Friction . . .

Have you ever tried to slide a cardboard box full of books or other weighty contents across a floor? Did you notice that the box was difficult to get moving, but that once sliding it became easier to push?

If so, you’ve experienced the difference between static and kinetic friction.

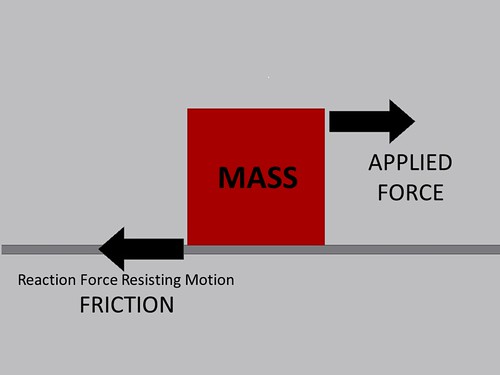

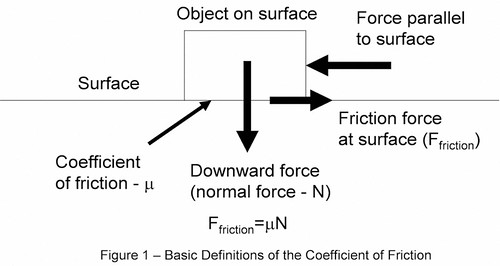

While it might seem counterintuitive, friction between two surfaces is greater when there is no movement between them. Once that initial bond is broken with an applied force, friction is reduced. That force can be a push or pull, as when you moved the box of books, or another force such as gravity. Put that same box of books on one end of a table and lift that end. The box will stay put until gravity overcomes the static friction, at which point it will slide right off the other end.

What does this have to do with us? The differences between static and kinetic friction explain many of the interactions between a vehicle’s tires and the road. Again counterintuitively, when your tires are rolling along in a straight line there is essentially no movement between the contact patch and the road aside from slight hysteresis in the tread. When you apply force to the tire, during acceleration, braking, or cornering, you’re still dealing mostly with static friction—right up to the point when the tire loses traction and begins slipping, when kinetic friction takes over. That’s why locking up the tires during a panic stop increases braking distance, why an early Porsche 911 whose rookie owner lifts off the gas pedal in a decreasing-radius turn is likely to wind up backwards in the bushes, and why a four-wheel-drive vehicle or motorcycle climbing a steep slope suddenly stops climbing when the wheels start spinning.

Rubber generates friction essentially three ways: though adhesion, deformation, and wear. Adhesion refers to the simple stickiness of the material. Adhesion friction is thought to be created by transient molecular bonding between the adjacent materials. Deformation occurs when the rubber in the tire molds to minute imperfections in the surface and creates a momentary mechanical bond (also called keying). Tearing is just that: if the tire’s tread material is stressed beyond its tensile strength, it sheds microscopic particles of material, and that process absorbs energy, which increases friction.

These principles apply to a tire turning on a loose surface as well, but in varying degrees. Frequently when a tire loses traction, it has not lost traction against the substrate directly under it; rather that layer of substrate directly against the tire is shearing against the material beneath it. You get an exaggerated example of this when a tire fills with mud and spins. A whole bunch of mud is sticking to the tire quite happily, but it’s slipping against the mud below.

Awareness of that frequently thin line between static and kinetic friction can help make you a better driver or rider. The trick is to balance the throttle (when climbing) or brakes (when stopping or descending) to keep the tires just this side of that edge. Of course, most modern four-wheel-drive vehicles incorporate computer-controlled devices that do some or all of it for you. I recently experienced Jeep’s Hill Descent Control (HDC) on a steep, bouldery downhill trail. Even though I was aware of the capabilities of the sytem, it was unnerving in an automatic-transmission vehicle to simply select low, push a button on the dash, and then head over the edge, foot off the brake pedal. I could hear the ABS engage the brakes on individual wheels to keep the speed down to a comfortable crawl. In my FJ40, even though it has a manual transmission and a very low first gear in low range, engine braking would not have been sufficient to control the speed on a descent this steep, and I would have been actively cadence-braking—intermittently pumping the brake pedal until the wheels almost locked—to approximate what the Jeep did on its own (except, of course, I could not have engaged the brakes individually). It was an impressive performance, if completely reliant on software.

Anti-lock braking systems are becoming prevalent on motorcyles as well—in fact the EU has mandated ABS on all bikes larger than 125cc beginning in 2016.

Likewise, modern traction-control systems such as Land Rover’s Terrain Response can detect when the static/kinetic line has been crossed, using speed sensors at each wheel, and will reduce torque to or brake a wheel that has lost traction on a climb or cross-axle ditch, sending power to the opposite wheel. I had equivalent terrain-conquering capability in the long-term 2008 (pre HDC) Jeep Wrangler Rubicon I drove for two years, but the software part of the equation was in my head, as I chose when to disengage the Jeep’s front sway bar to increase suspension compliance, and when to engage the front and rear differential lockers to prevent wheelspin. The single real-world advantage there was the fact that, unlike Terrain Response, I could tell when a difficult section was coming up several feet before I actually reached it, and take the appropriate actions proactively. Terrain Response (and its cousins) can only respond when its sensors detect that a wheel has lost traction, a second or two after the static/kinetic line has been crossed. Nevertheless, these automatic systems make child’s play of situations that used to require considerable finesse and experience.

Is that a good thing or a bad thing? You decide—but, just as when navigating with GPS versus map and compass, it’s a wise thing to have backup skills. If someone with a new Range Rover were to ask me the best way to become proficient at off-pavement driving, I’d say, “Buy a Series III 88 and start with that.” If you can master a manual-transmission, straight-axle, leaf-sprung, open-diff Land Rover—and the concept of static versus kinetic friction—you’ll be able to climb back in the Range Rover and soon have that computerized wizardry doing your bidding, instead of just being along for the ride.