Antigravity’s new LiFePO4 batteries

One morning in the early 1990s, when I was still leading sea kayaking tours in Mexico, I found myself stranded on a remote beach at the end of a tour with a suddenly dead Sears Die-Hard battery in my FJ40 (this was before I’d ever heard of a dual-battery system). Rather embarrassed, I got a jump start from a client, sent everyone home ahead of me, then drove the entire way back to Tucson, towing a trailer full of kayaks, without turning off the engine. (It took some doing to convince the U.S. customs people I wasn’t just preparing to do a runner after I was pulled into the inspection lane. In an FJ40 pulling a trailer? They could have caught me on foot.)

Not the best place for battery failure.

The battery was well within its pro-rated warranty period, so once home I got a new one for around half price. But that really wasn’t the point, was it? If I’d sent everyone home before discovering the dead battery, I would have had a very long walk to the nearest fishing village—I certainly couldn’t have push-started an FJ40 solo in beach sand. I was also aware of other circumstances I’d been in that could have been as bad or worse if a battery had failed. My experience with Die-Hards—then the much-hyped premier battery on the market—was that they lasted an average of two years before failing, usually abruptly.

There had to be a better way. I did some research (remember when that took actual effort?), which led me to news of a recently available type of über SLA (sealed lead acid) battery called a “gel cell” or AGM (for absorbed glass matt). A company called Optima made them, and the one that suited my FJ40 was around $130 special order—an outrageous price when a Die-Hard went for $55. I winced and ordered one anyway, and that first red-top Optima lasted six years before—very politely—showing signs of weakening. Thus, not only did it prove less expensive in the long run, it saved me at least two battery failures that could have happened anywhere. The AGM battery (I switched to Odyssey later on) became my standard battery configuration—as did a dual-battery system.

Twenty five years later there is a new über battery on the market, with a price as startlingly higher than a typical AGM as that Optima was higher than the Die-Hard. Does the lithium iron phosphate, or LiFePO4, battery represent as much of a leap as the AGM did? Can an overlander on a modest budget justify spending $800 or more for a single battery?

I’d like to find the answer—for myself as well as readers who might be contemplating the upgrade. So I’ll be installing a new dual-battery system in our Land Cruiser Troop Carrier, using one of Antigravity’s new DC-100-VI deep-cycle LiFePO4 batteries, along with one of their already introduced LiFePO4 starting batteries.

Not your father’s car battery . . .

I’ve been a fan of Antigravity’s products since their pioneering, pocket-sized Micro-Start jump-starting unit, which I embraced very early on and with which I’ve astonished more stranded motorists than I can count, including dozens at several Overland Expos who immediately headed for the Antigravity booth to buy their own. I also astonished, and rather horrified, Scott Schafer, the founder of the company, when I called to tell him that Tim Scully and I had successfully daisy-chained three Micro-Starts and performed an excellent field weld. That function was definitely not within his original design goals—yet we still have all three of those units and they still work perfectly.

NOT recommended!

Given that history, I have every expectation that Antigravity’s LiFePO4 automotive batteries will display similar quality. But I had to promise Scott I wouldn’t try welding with them.

So what’s all the fuss about LiFePO4 technology?

Most articles covering lithium batteries (to use the convenient shorthand) immediately mention the weight savings. And that aspect is impressive—The 100-amp-hour deep-cycle battery Antigravity sent me weighs 30.5 pounds; an equivalent Odyssey AGM unit weighs 69.5. Switching to a dual-battery system employing both starting and deep-cycle lithium units will, in our case for example, completely offset the weight of our 60-liter National Luna fridge-freezer. With a case of beer inside.

Thus there is an obvious advantage in energy density to the lithium battery. However, it’s even greater than the weight difference implies.

Consider a deep-cycle AGM battery and a deep-cycle LiFePO4 battery, each rated at 100 amp hours. While that seems equivalent on the surface, in delivery it is not. As soon as a draw is placed on an AGM battery, its voltage begins to drop in a more or less linear fashion. Once that voltage drops below 10.5 or so, a 12V appliance such as a fridge will shut itself off. At that point the battery retains nearly 50 percent of its theoretical energy, but it is unavailable to a 12V appliance because the voltage is too low.

By contrast, the energy delivery of a LiFePO4 battery is a nearly flat line that remains above 12 volts until the unit is almost fully discharged, at which point it drops off rather rapidly. Thus you get far more actual available power from a lithium battery than you would from an “equivalent” AGM.

But that’s not all. A LiFePO4 battery is also capable of accepting a charge at three to four times the rate of an AGM battery. A typical AGM in a vehicle can take as long as 10 hours to recover from a completely discharged state. A LiFePO4 battery can be recharged completely in four. And while an AGM battery typically can withstand around 300 such discharges, a lithium battery can withstand around 2,000—which brings up the last comparison: lifespan and amortized cost.

Currently a high-quality LiFePO4 battery costs two and a half to three times as much as a high-quality AGM battery from a manufacturer such as Odyssey. However, it appears likely the lithium battery will outlast the AGM battery by about the same factor—if not more. Thus over time the LiFePO4 battery should recoup its cost—and that doesn’t count the hassle of having two or three AGM batteries fail in that time. On an amp-hour basis, there’s no comparison—the LiFePO4 delivers far more energy over its lifespan.

(This obviously assumes that you keep your vehicle for a long time, or that you swap the lithium batteries from old truck to new truck, and say, “Get your own!” to the buyer of the old one.)

There are other advantages. For example, the Antigravity lithium starting battery has a built-in wireless jump-start feature. Leave the lights on or in some other way run down the battery, and it will shut itself down while retaining sufficient starting power to start the vehicle. Just tap a button on a wireless key fob to activate it; you don’t even need to open the hood. (You can also hit the button on the battery itself.)

So . . . end of argument? Not quite.

The bête noire of the LiFePO4 battery is temperature, or rather temperature extremes. Most lithium automotive batteries, including the Antigravity unit, can be used (i.e. discharged) at temperatures down to -20ºC (-4ºF). However, they cannot be charged at temperatures lower than about 0ºC (32ºF). The Cliff’s Notes reason for this is that, when recharging at temperatures above 0ºC, the lithium ions are absorbed by the porous graphite that comprises the anode—the negative side of the battery. Below this, the lithium instead begins sticking to the outside of the graphite, a process called lithium plating. This not only reduces efficiency but can permanently damage the battery.

Keep in mind that these critical numbers represent the internal temperature of the battery, not the ambient air temperature. As the outside temperature drops, the internal battery temperature will lag significantly. A night that drops to freezing or even several degrees below is unlikely to chill the internals to critical level—and we never charge batteries at night anyway. Also, drawing power from the battery—even for efficient LED camper lights—raises its internal temperature somewhat.

Fortunately, each Antigravity battery incorporates a sophisticated battery management system (BMS), which prevents charging when the temperature drops too low. So you don’t have to worry about damaging the battery; however, this aspect might be important if you camp for long periods in persistently below-freezing weather. Antigravity is also preparing to introduce a LiFePO4 battery with an automatic internal heat source that runs off the battery itself, as some other manufacturers have done. We don’t feel the need for this in our application—for Roseann, the words “snow” and “camping” never appear in the same sentence.

(As usual, clever owners who adopted LiFePO4 technology ahead of the rest of us have figured out their own hacks to deal with the low-temperature issue. Some have combined a simple temperature-controlled switch such as this with an inexpensive 12V heating film like this.)

(Another parenthetical aside: While researching all this I came across an article detailing the efforts of NASA scientists to extend the low-temperature parameters of lithium batteries—of obvious importance when sending them into space. The article noted that engineers had significantly extended these parameters by using an electrolyte formation of—ready?—1.O MLiPF6EC+DEC+DMC+EMC (1:1:1:2 v/v) and 1.O M LiPF6 EC+DEC+DMC+EMC (1:1:1:3 v/v). If they’d only called me I would have suggested that in the first place.)

Very high temperatures can also affect LiFePO4 performance. The listed upper limit for discharging the Antigravity deep-cycle battery is 55ºC (131ºF). For this reason, some owners install their lithium “house” batteries inside the vehicle or camper rather than in the engine compartment. This has the doubled effect of keeping the battery warmer on cold nights, especially if any kind of heat source is used in the camper for the comfort of occupants.

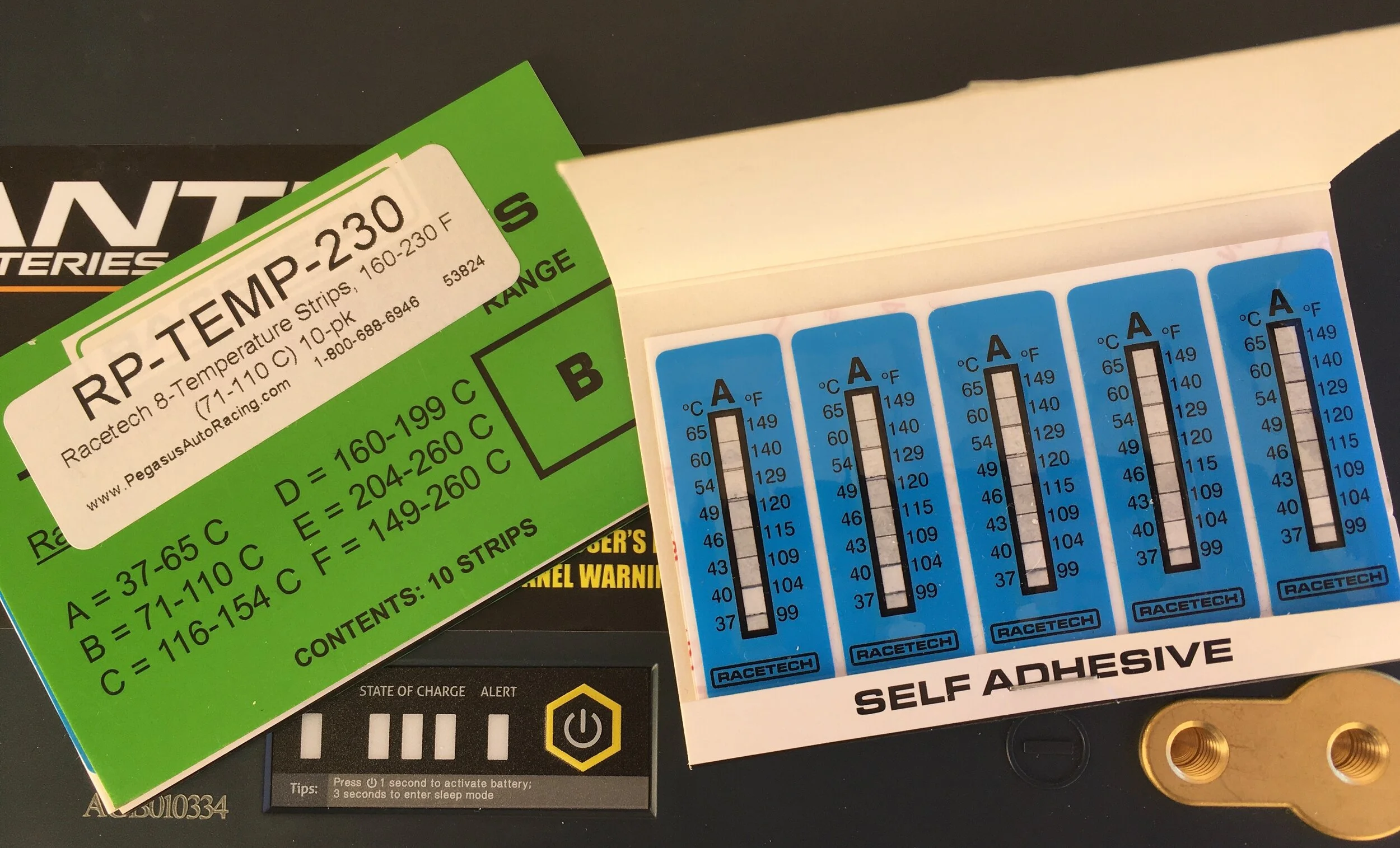

I’ve decided to take a slightly bolder approach, partially as an experiment to see the effects of different installations. Our Troopy has the stock dual-battery tray in the engine compartment, and I plan to mount both batteries there and monitor the temperature extremes they experience, using (in part) Racetech stick-on temperature strips, which record the high temperatures reached on the surface to which they’re attached.

The other part? That will be courtesy the built-in Bluetooth connectivity of each battery, which will enable me to monitor, through my iPhone:

Battery voltage

Current/amps going in or out

Watt output

State of charge percentage (SOC)

Interior temperature

Individual cell voltage

Number of cycles the battery has experienced

In addition to that internal temperature readout, the state of charge in percent will be especially helpful—given the LiFePO4’s characteristic of maintaining flat voltage delivery, it’s difficult if not impossible to ascertain the state of charge by voltage alone, as on an AGM battery.

Our Troopy’s battery tray is in the back right corner of the engine compartment, looking from the front of the vehicle. The 1HZ diesel’s exhaust manifold is on the opposite side of the engine, which will help mitigate heat gain. I also plan to have fabricated a metal heat shield that will block the inside faces of the batteries, to help even more. I’ll add some sort of heat barrier to the sheet metal as well. In a few months the southern Arizona summer should give us some solid data on the effects on both batteries; then we can re-evaluate their placement.

I’m going to take the opportunity to replace the existing cables and terminals with new ones, and clean up the rather tangled routing resulting from adding on the winch, driving lamps, and National Luna isolator.

There is one other cost factor to consider when considering a LiFePO4 battery. As I mentioned, a lithium battery has a very different charging profile from an AGM battery. Thus, for the deep-cycle unit I’m installing in the Troop Carrier, I’ll need to swap the existing DC-DC charger, designed for AGM batteries, for one that includes a setting for lithium batteries and is suitable for routing and managing both alternator and solar power to the Antigravity battery. Such units can run from about $300 to $400. This is pretty much a one-time outlay, but it still needs to be factored into the initial investment.

I’ll be doing regular updates here as soon as the starting battery arrives.