Parabolic springs: What exactly are they?

ARB/Old Man Emu recently announced, with great fanfare, a rear suspension kit for the 70-Series Land Cruisers that includes a two-leaf parabolic spring for each side, plus adjustable air bags to compensate for overload conditions. It can replace a standard semi-eliptic spring pack that might require 12 or more leaves to support an equivalent load.

Other manufacturers, such as Terrain Tamer, have also introduced parabolic springs kits for 70-Series Land Cruisers, as well as Series II and III Land Rovers.

But what exactly is a parabolic spring? And is it really better than a standard leaf spring?

The individual leaves of a standard, semi-eliptic, multi-leaf spring pack are stamped and then bent from strips of heat-treated, medium- to high-carbon steel, more or less rectangular in cross section, and of consistent thickness and width the length of the leaf (except for, in some cases, when the ends are rounded or have the corners relieved). When attached to a simple pivot at one end, with the other free to rotate a movable shackle, a single leaf resists bending in a fairly uniform fashion throughout its travel. To increase strength—that is, load-carrying ability—and add progressive resistance, progressively shorter leaves are added beneath the top leaf, held loosely in place with floating brackets that do not restrict movement. As the spring pack is compressed, each leaf slides against the adjacent leaves. This inter-leaf friction results in a self-dampening effect—unlike, for example, a coil spring, which has little internal resistance and relies almost entirely on a shock absorber (damper) to control oscillations.

However, that inter-leaf friction also degrades the ride quality of a leaf spring as well as its compliance—the ability to compress or extend fully. And this effect worsens as the spring gets dirty and/or rusty. Some manufacturers (such as OME) install replaceable anti-friction pads at the leaf tips, which help noticeably but do not eliminate the problem.

Years ago a few manufacturers—among them Nissan—attempted to create a progressive-rate leaf spring by making the leaves thicker in the middle, tapering in a linear fashion to the tips, as in the (very) simple schematic below. This involved a relatively easy manufacturing process. However, these “taper-leaf” springs proved less than ideal as bending stresses were not evenly distributed through the length of the leaf, resulting in weak points and failures.

Enter the parabolic spring.

While it’s difficult to discern looking at it from the side, the thickness taper of a parabolic spring follows a complex mathematical formula. Rather than simply tapering straight from the center of the leaf to the end, a parabolic spring looks like an extremely stretched-out version of the illustration below. As you might imagine, it’s significantly more difficult—i.e. expensive—to design and manufacture than simply stamping out flat lengths of steel and piling up enough of them to support a load.

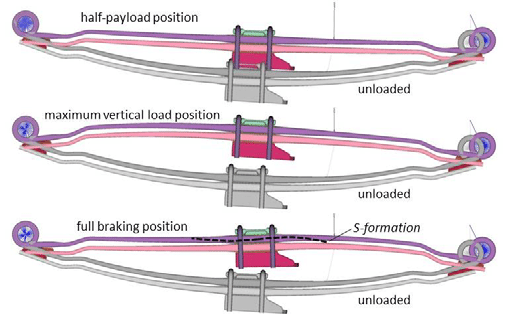

The results, however, are worth it. Not only is a parabolic leaf progressive in its operation, it is also nearly as compliant as a coil spring due to the lack of internal friction and stress. Theoretically a single parabolic leaf would be sufficient to function as a spring; however, due to the ramifications if the leaf did break, most parabolic spring kits for vehicles comprise at least two leaves, and the lower leaf will have a full military wrap on each eye, to contain the upper spring should it break. These leaves touch only at the spring seat in the middle, and at the ends, so there is virtually no interleaf friction. Most kits also include a free-floating overload leaf that only engages under high load or compression. The illustrations below are from a (densely technical) Researchgate-published paper on leaf spring design, available to read or download here.

There’s more: A parabolic spring equivalent in load-carrying capacity to a standard multi-leaf spring weighs at least 30 percent less, drastically reducing unsprung weight and further improving ride and handling. Convert an all-leaf-sprung vehicle to parabolics and you could take 80 pounds off its total mass.

The conversion job is straightforward, no more complex than changing out standard springs, although the vehicle will almost certainly require new, firmer shocks to compensate for the loss of inter-leaf friction. Series Land Rover owners I know who’ve converted describe it as “transformative.” This diagram shows the magnitude of travel possible with a parabolic spring system, as well as the longitudinal “S” deformation any leaf spring undergoes during severe braking.

While it’s easy to find parabolic spring kits for Series Land Rovers and the 70-Series Land Cruisers, diligent searching revealed no such kits for my FJ40, although I heard that one company did offer them for a while years ago. Damn. (Edit: See later articles for much better news!)

Incidentally, there is no relation between the terms “semi-elliptic” and “parabolic” in leaf spring terms. Semi-elliptic refers to the shape the entire spring pack assumes from the side; if one were to draw this shape out into a connected oval, it would be roughly elliptical. A parabolic vehicle spring pack assumes this same profile and is thus also semi-elliptical.