Overland Tech and Travel

Advice from the world's

most experienced overlanders

tests, reviews, opinion, and more

New Safe Jack universal base plate . . . and a sale

I’ve written several times before about Safe Jack’s unique products. Read here and here about the expanded base plates they invented for the Hi-Lift jack and bottle jacks, which transform the nature of both kinds of lifting tools.

Previously you had to choose which base you wanted. Now Richard Bogert of Safe Jack has introduced a universal base that accepts either a Hi-Lift base, or a clip-in plate on which almost any standard bottle jack can be clamped. So during a recovery situation in soft substrate, when you need the extra flotation for your Hi-Lift (or the clever and rock-solid guy-wire stabilizing system), you’ve got it, and when you shortly thereafter need to jack up one wheel for a tire repair, you can just snap in a bottle jack to the same base. Nice.

Safe Jack will be at Overland Expo WEST with show specials. If you won’t be there, don’t feel bad: Richard will be running a “Gear up for Overland Expo” web special through May 20th. The website is here, and the promo code is GEARUP2016.

Battery welding done right

The magic of battery welding has been known to field mechanics for years now, and one of the most popular classes at the Overland Expo is the hands-on introduction to the skill, taught by experts such as welding wizard Tim Scully. Briefly, by combining several standard automotive batteries in series—that is, positive terminal to negative terminal, in a chain—you create in effect one large 24V (with two batteries) or 36V (three batteries) cell, and this produces enough power to weld a lot of things that can be prone to breaking on vehicles used in rugged conditions: shock and spring mounts, motor mounts, ancillary brackets, roof racks—the list is endless, and full of items that can bring a trip to a sudden halt.

Until now, most impromptu battery welding has been jury rigged with standard jumper cables. While this works, it is far from ideal. Jumper-cable wire is cheap stuff designed for a few second’s starting duty at a time; its coarse strands are inefficient at conducting the power produced by series-connected batteries. And the toothed clamps, although adequate for attaching to battery terminals, are poor for gripping slender welding rods. In addition, you need a way to connect the batteries to each other, which either requires another set (or two) of jumper cables, or yet more jury rigging with your existing battery leads.

All that just ended, thanks to the Trail Weld kit, developed by Tim Scully himself. Tim evaluated the compromises that go into the normal battery-welding setup, and fixed them all.

- The cables are now fine-strand, four-gauge Temco welding wire, with 360-degree crimps on all fittings. A 12-foot length on positive and negative leads allows you to put a safe distance between the batteries and sparks. The flexible cable makes controlling the clamp and rod much easier.

- The positive lead ends in a proper welding-rod clamp, and the negative lead ends in a dedicated ground clamp.

- Two short leads of Temco wire make quick work of connecting batteries, and reduce voltage loss.

- All battery connections are high-quality terminal clamps, greatly enhancing conductivity and thus efficiency.

- All connections are color-coded with heat-shrink wrap.

- A selection of correctly sized welding rods is included in a plastic protective case.

- A pair of self-powered auto-darkening goggles is also included.

- Available containers range from a simple bag to a .50-caliber ammo can to a Pelican Case.

The complete system is so efficient that Tim reports two batteries are sufficient to weld material that requires three if using jumper cables. As he told me, “If you are using three batteries you’d better be welding at least quarter-inch-thick stock.” Since an increasing number of overland vehicles these days are equipped with two batteries, that means you can be completely self-sufficient for field-welding repairs.

For welding amateurs such as myself, the auto-darkening goggles make all the difference when welding with rod, as there’s no pre-positioning the rod at the correct gap and then fumbling with a standard goggle or, worse, a jury-rigged square of welding glass taped to a cardboard face shield, as I’ve always carried. (Of course you’ll still want face, arm, and hand protection.)

For more information, visit the Trail Weld site, here. At the upcoming Overland Expo WEST, Trail Weld kits will be on display during the welding classes, and available for purchase at the 7P booth. Highly recommended.

Buy the tire you need, not the one you want

Recently I received a set of the all-new Yokohama Geolandar AT GO15 tires to review for OutdoorX4 magazine. While sold as an “all terrain” tire, the tread on this Geolandar looks mild compared to many similarly marketed tires. And that got me to thinking about overlanders and our tire choices.

It’s natural to gravitate toward an aggressive tread design when buying tires for a four-wheel-drive vehicle. A more aggressive tread means better traction in steep or loose terrain, right?—which is why we have four wheel drive in the first place, right? And besides—let’s be honest—a mud-terrain tire just looks cooler than a more street-oriented “AT” tire. If appearance has never, ever entered into your tire-buying decision you’re a more logical thinker than I am.

Obviously, however, there are logical aspects to tire selection besides traction. The most critical of these—in fact the most critical of all— is safety. A street-biased tire with more closely spaced, shallower tread blocks will exhibit significantly better grip for both handling and braking than one with hyper-aggressive, open-blocked tread. That aspect could quite literally be a lifesaver in the right (wrong) scenario.

Fuel economy is a factor as well. When I switched from BFG All-Terrains to BFG Mud-Terrains on my FJ40 (partially because, yep, they just looked better) my fuel economy dropped by almost exactly one mile per gallon—and one mile per gallon on an FJ40 makes a difference, let me tell you. Then there’s tread life. Those closer tread blocks translate to less squirm, which translates to longer tread life given the same compound. Finally, even with modern computer-designed tread, aggressive tires tend to be louder at high speed, which can be a fatigue factor on long drives.

All these advantages to street-biased tires are obviously mostly advantageous on the street, and that’s where logic butts up against romance. Most of like to think we spend more time off pavement than we actually do. The reality is, if more than ten percent of the miles you put on your overland vehicle are actually off pavement, you are quite an adventurer. I’m not sure Roseann and I hit that, and we cover seven miles of dirt road just to reach our house. Much more frequently a backcountry journey will entail several hundred miles of highway and maybe 40 or 50 miles of trails. Thus, for most of us, for most of our time behind the wheel we would enjoy better handling, braking, fuel economy, and tread life with a less-aggressive tire choice. And we wouldn’t have to crank up the sound system so much to count how many times Terry Gross says “like” or “um” in one interview. Sorry, personal gripe.

Where was I? Right: There’s an additional factor to consider for those of us who own modern vehicles with sophisticated ABS-based traction systems and hill-descent control: We have more and better inherent traction available to us than we did when driving older vehicles with simple part-time four-wheel-drive systems. So we can enjoy just as much off-pavement ability with a less-aggressive tire—as anyone can confirm who’s watched Land Rover’s LR4s on street tires negotiate the Overland Expo driving course.

So the next time you buy tires for your overland vehicle, consider carefully—and logically. Do you really need those BFG Mud-Terrains, or would the All-Terrains perform better most of the time? For that matter, would BFG’s Rugged Trail suit your needs? Get the tire that works best, not the one that looks best. Then you can smile condescendingly at the guy driving by in the jacked up truck riding on those howling Super Swampers.

Energy independence . . . for your overland vehicle

This will come as a shock to many of you, but it is actually possible to camp without electricity.

Reliable visual records from the Middle Ages (1950—1985) clearly show families surviving—even, at times, apparently enjoying themselves—in campsites lit only by white gas or propane lanterns, retrieving food from insulated boxes cooled only with ice, and engaging in such non-electrically dependent activities as fishing, swimming, climbing trees, and reading books manufactured in the ancient Gutenberg manner, on paper. (A few disputed images even purport to show family members talking to each other.)

Of course it’s easy to idealize scenes in vintage Kodachrome transparencies. What isn’t so apparent are the tragic effects of those primitive times: respiratory problems from second-hand kerosene smoke, salmonellosis caused by eating chicken stored at above-optimal temperatures, blindness brought on after repeated attempts to read Field and Stream by the light of a candle lantern (not to mention the devastating tent fires also associated with open flames), ugly cases of fratricide sparked when siblings were forced to interact directly with each other. (“Where’s Timmy?” “I don’t know, mommy. Maybe a bear ate him.”)

We can thank the advances of civilization—the Cree, the Engel, the earbud—for the blessedly longer median life expectancies now enjoyed by overland travelers. But LED lanterns, 12V fridges, and the myriad of electronic entertainment and communication devices now virtually grafted to our persons—they all require electrical power. Those of us who’ve moved even farther upmarket with such things as truck-mounted campers need yet more, for water pumps, vent fans, heater blowers . . . although personally I’ll draw my line of sympathy this side of anyone who wants to power a flatscreen TV in the wilderness.

An auxiliary deep-cycle battery has become nearly standard equipment for a well-sorted overland vehicle, and with good reason. It keeps the starting battery free for its critical duty, and serves as a starting backup as well if connected with a selectable isolator such as the National Luna (although the advent of the brilliant Micro-Start and similar products has made this function nearly redundant). With a battery monitor it’s easy to keep track of usage and voltage.

However, depending on load (especially that fridge), you can run down even a high-quality Group 34 AGM battery in anything from six or seven days to less than one. If you’re on the move day to day, it’s likely your engine’s alternator will be more than adequate to bring the voltage back up to an ideal float level of 13.4 volts or so. But what if you’ve found the perfect beach or forest campsite and don’t want to move for a week, or two? Idling the engine is a notoriously poor (slow) way to recharge a battery, irrespective of the fact that you’re pointlessly burning fuel, causing pollution, and spoiling your ideal campsite with noise. You need a different power source—and the finest one you could ask for is a mere 93 million miles away.

For years auxiliary photovoltaic (PV) solar panels for vehicles fell into two broad categories and capabilities: You either had a permanently mounted rigid unit or units of decent (50 to 200 watts) output installed on the roof with brackets, or you made do with much smaller flexible PV panels which clipped directly to your battery and could be laid out on either the hood, roof, or ground. The former, while sometimes capable of maintaining auxiliary battery voltage nearly indefinitely, were bulky and heavy, and created serious overhead hazards for tree limbs, etc. The latter were rarely if ever capable of doing more than delaying the necessity for running the engine.

That’s all changing. Roseann and I now have two 100-watt semi-rigid PV panels on the roof of our Four Wheel Camper; attached directly to the roof via stout adhesive backing, they create essentially no windage or clearance issues, and over many trips have proven to keep our auxiliary fully topped up to run the camper’s fridge, (LED) lights, vent fan, and water pressure pump, and recharge capabilities for our extensive array of journalist-oriented electronic devices and cameras.

And now it’s possible to get that same level of input with a completely portable kit displayed by P3Solar at the Overland Expo. Their 200-watt flexible panel weighs barely five pounds, and rolls into a 35-inch by 5-inch tube. While it obviously takes more time to set up than a permanently mounted panel, you can use it on different vehicles, and if you want to park in the shade you can run the panel out into the sun (although since the panel is equipped with bypass diodes it handles partial shade quite well). Your roof is also now free for bicycle or kayak racks, or a roof tent.

The P3Solar panel connects with standard 2-pin SAE plug. You could run that through alligator clips and simply hook it up directly to your battery, but with that much input you’d need to monitor the system very carefully to avoid exceeding maximum voltage. Much better to run it through an MPPT (maximum power point tracking) charge controller, which will optimize the unit’s 24-volt output. A standard charge controller will work as well, but will pull the voltage down a bit and thus not exploit the panel’s full output.

The panel can be deployed by laying it flat on the ground; however, the company also offers a clever folding aluminum frame that positions the panel at a more optimum angle for those in latitudes above the tropics. It expands accordion-like in about five seconds and snaps into place; the panel then attaches to it securely with Velcro. The frame can be (that is, should be) staked to the ground with included stakes that are stouter than anything I’ve ever seen included with a family sized tent. Impressive. Thus anchored the assembly shrugged off a 20mph breeze out at our desert camp; Wally Stoss at P3Solar assures me it’s been tested at over twice that. The EZ-out kit include a larger diameter bag and a rigid tube to separate the panel and frame, and the whole kit is still under 20 pounds.

On a very warm (95ºF) summer morning with the sun still low, I recorded a bit over 100 watts out of the panel mounted on the frame. Since PV output is lower in high temperatures, and obviously lower when the sun isn’t directly overhead—and since most PV panels never see their theoretical maximum—this is astounding performance. Most fridges draw in the neighborhood of three amps (36 watts at 12volts—and of course only intermittently), so I was already well ahead of that.

It’s clear the P3Solar panel would give most overland vehicles complete electrical independence—and then some—for as long as you wanted to stay and enjoy that beach. I’m curious what the output of this panel will be in colder temperatures with the sun overhead. Imagine selling your excess electricity to fellow campers . . .

P3Solar is here.

Inflate tires with your Micro-start

I make no secret of my continually renewed admiration for Antigravity Batteries’ Micro-Start XP-1 and XP-10 battery pack/jump-start kits. The half-dozen or so of them scattered among the Overland Expo training team have been used and abused beyond reason, and they continue to function. We’ve started everything from motorcycles to 460-cubic-inch gasoline engines to turbodiesels. We’ve hooked three in series and produced excellent field welds (much to the horror of company president Scott Schafer). We make sure one is in any vehicle we’re driving.

Motorcyclists have begun carrying the smaller XP-3 and XP-5 Mini, freeing them as well from the tyranny of jumper cables or the need for a good Samaritan if caught with a discharged battery. Now Antigravity has come up with a cunning little air compressor, about the size of a sandwich, that can either be powered from a Micro-Start battery or plugged into a standard cigarette lighter socket.

I expected it to perform as well as the company’s other products, and it did: A quick test on Roseann’s R80 G/S took the front Continental 90/90-21 tire from 8 PSI to 35 PSI in two minutes flat, and the compressor didn’t even get warm doing so. The inflation hose is only about three inches long, so the pump simply hangs off its screw-on chuck. A dedicated 18-inch cord connects it to a Micro-Start power source (I used our XP-1); the ten-foot cigarette-lighter cord is long enough to reach into a vehicle or to another motorcycle.

Of course, since this is a Micro-Start product, there's by now a certain assumption we'll abuse it. So I left the compressor hooked up to the power pack and connected it to a 235/85 16 BFG AT KO2 on our Tacoma. Ambient temperature was 95ºF. The tire was at 20 PSI; 16 minutes and 30 seconds later it had reached its nominal 40 PSI, and the compressor, while quite warm to the touch, was still buzzing away happily. The power pack still showed three of five status lights. So, while I certainly wouldn't use this as a primary compressor for a four-wheeled vehicle, in a pinch it would suffice.

What more can I say, except I hope the manufacturer edits the features list on the box. The tire inflator is yet another excellent offering from Antigravity Batteries. And at $25 it is a bargain.

A more storage-friendly sand mat

The one big problem with proper, rigid sand mats is their size. Storing them inside the vehicle is a pain due both to bulk and their ability to damage nearby gear or luggage. Outside storage demands either a roof rack, a rear tire-carrier rack, or some other specialized arrangement.

So I was intrigued to stumble upon the Traction Jack, a two-piece sand mat only 25 inches long when folded. A pair fits inside a box about a foot wide by six inches deep.

The Traction Jack is stoutly built—in fact a pair weighs a substantial 28 pounds (compared to just 18 for a pair of MaxTrax). They are rated to 1,900 pounds per tire each, which easily handles most overland vehicles; a special-order version molded from high-strength nylon boasts a 4,500 pound per tire rating, which is up in fully loaded Unimog territory.

Obviously, the hinged Traction Jack will be of absolutely no value for bridging, even compared to the relatively flexible MaxTrax, which bridges surprisingly well when doubled. On the other hand, the two-piece construction of the Traction Jack should virtually eliminate kick-up into the vehicle's bodywork as you drive on or off it.

The company cautions against wheel spin when driving a tire onto the mat, as excess heat can melt the poly composite nubs that provide grip. I'm not sure how one would completely eliminate wheel spin when buried in sand; I expect a little extra pre-recovery shovel work would help—which is a good idea anyway. Fortunately the company's excellent guarantee grants one free replacement of a damaged section, and a discount on further replacements. By then one would hope to have learned the proper technique. It seems to me larger nubs would reduce the issue and provide more traction as well, but I need to test these in the field to be sure.

Even folded, the Traction Jack is thinner than a MaxTrax.

Besides ease of storage, another advantage to the Traction Jack is price: At $180 per pair (black), they undercut the MaxTrax by $120.

Competition in the sand mat/bridging ladder market seems to be heating up. The excellent MaxTrax has in a short time become a (slavishly copied) standard by which other one-piece sand mats are judged. I think the Traction Jack will provide a viable alternative for some people, giving up some versatility (bridging) in exchange for convenient storage options.

The Traction Jack website is here. I'll have a pair with me at the Overland Expo. Come by the BFG booth where the sand pit tire demo area is. I'll try to keep them there.

A dual-band radio for the JATAC

If you do any overlanding with a group, especially in remote areas and on routes where the vehicles might be out of sight of each other for periods, it’s smart to have some means of intra-group communication. Cell phones are okay for person-to-person talking, but cell coverage is still far from universal (more so where many of us like to explore), and in any case a phone is worthless for broadcasting a quick message to multiple vehicles at once. For that you need a radio.

Handheld UHF (Ultra High Frequency) FRS (Family Radio Service) transceivers are okay for very short-range work, as are the CB (Citizen’s Band) radios made famous by the 55mph speed limit, Smokey and the Bandit, and several bad country songs. But if you want some real range you’ll need to go the pro route and install a two-meter transceiver.

Two-meter communication uses the 144 to 148 MHz band of the spectrum. Due to the frequency allocation, and the power allowed to the units, range is significantly greater than possible with FRS or CB units—and it can be extended even farther by using repeaters. You need an FCC Technician Class amateur radio license to operate a two-meter radio, but the test is easy to pass after a review of the associated technology and rules available several places online, such as here. I’ll never live down my test, when I missed one question out of 35 while Roseann at the next desk aced hers. I should have cheated. (If you are attending the Overland Expo, you can study on your own, then pay the nominal fee and take the test at the Expo on Sunday between 8:00 and 10:00 a.m.)

For some reason I kept putting off installing a two-meter radio in the JATAC—we used a handheld throughout the entire Continental Divide trip last year, which is pretty lame for the trip leaders. So I rectified the situation for this year’s upcoming CD journey.

On the advice of ham-radio guru Bob McNamara (a frequent instructor at the Overland Expo), I ordered a Yaesu FT-8800R/E dual-band transceiver. Operating either in the two-meter or 70cm bands, the FT-8800R/E can put out 50 watts of transmitting power on the former (compared to five for most handhelds), and has a bunch of additional features that will take me years to master. If you’re faced with a difficult installation scenario (common in modern trucks with crowded dashes and even more crowded wiring harnesses behind them), the faceplate can be mounted on its own, connected to the remotely positioned main module with an included cord. It turned out in our case (2012 Tacoma), that a pocket in the center console just in front of the (manual transmission) gear shift seemed almost deep enough for the entire unit. I needed to pull everything out to determine if that was the case.

Modern truck interiors are a bit of a jigsaw puzzle. Taking one apart can be an hours-long struggle or—if you know the sequence—a matter of minutes. A call to our friend and master Toyota mechanic Bill Lee (who, annoyingly, keeps moving farther and farther away—first 250 miles, now 400 and counting*), and I had the secret to the center console. The cup holder assembly is held in by clips; pop it straight up and a couple of bolts and screws underneath release the rest of the assembly.

I cut a hole in the back of the pocket large enough to accept the back of the radio and allow access to the power cord, antenna, and remote speaker jack. However, a trial fit revealed something else in the way: a large, bolstered plastic tab extending vertically downward from the dash structure itself. Even Bill had no clue as to its function. Its position directly above the air bag computer implied a relationship—some sort of protection? In any case it was barely but indubitably in the way of the antenna jack, so I unceremoniously took a hacksaw blade to it and cut off just enought to create a path for the antenna cable. Wit that accomplished, another trial showed the radio to sit nicely, clear of all movements of the shift lever.

Note the grey mystery tab on the right. Relieving a notch out of the left side allowed clearance for the antenna lead.

I’d bought a quick-release bracket for the radio; removing the console and loosening a few bolts on the bottom dash section gave me barely enough room to get my hand in behind and above the support piece to install stainless 10/24 locknuts and washers on the bolts holding the bracket. Amusingly, the perfect tool to drill the holes for those bolts through the plastic, with little maneuvering room, proved to be the awl attachment on my Swiss Army knife.

With the radio in place, it was time to run the positive and negative leads of the power wires through the firewall. In my old FJ40 such a task is easy: Find a blank spot on the steel firewall, drill a hole, run the wires through it and shove in a rubber grommet. Done. Today’s trucks are different. There are multiple layers of plastic, carpet, and soundproofing to get through—and masses of wiring to avoid—before you even reach the firewall. Fortunately, on the driver’s side of the Tacoma is a very large rubber seal through which a bunch of wiring connects the engine and battery to the dash. I found a phillips screwdriver with a long shaft, taped the end of each radio lead to it, and poked through the seal into the engine compartment. The Yaesu positive and negative leads are each equipped with inline fuse holder, and I wanted to be able to use the radio even with everything else in the truck turned off, so I ran the leads directly to the battery. (This is a good idea anyway, as a transceiver requires full voltage to function properly, and wiring from the vehicle's fuse box can introduce spurious electrical noise. The FT-8800 has an adjustable auto shut-down function to prevent draining the battery.)

For the antenna lead I found an existing hole in the passenger footwell, up behind the vent fan assembly. After removing the rubber plug in it, I had to file a slot in the hole to get the antenna lead through it, but it went through easily afterwards with the glove box assembly removed for access.

I had several options for mounting the antenna, but decided on a hood lip mount—a Comet RS-840 with a PL-259 connector—and a Comet CSB-750A dual-band antenna. The mount adjusts to enable a vertical stance for the antenna—I can’t stand tilted antennas—and in addition to clamping to the lip of the hood with four hex-head screws, has a brace that extends to the fender to enhance rigidity. On our truck the brace didn’t rest against the fender lip, resulting in an obnoxious side-to-side wobble in the antenna, so I glued a thin piece of rubber to it. That made a solid connection. Once mounted thusly, you don’t want to close the hood as so many people do, by dropping it from a foot or so high. Since I’ve always loathed this habit, and instead close all hoods by lowering them gently over the safety latch, then pushing down, this is not an issue for me.

One other note here: The antenna needs to ground to the hood via the four hex-head clamping screws. On the Tacoma hood, the edge underneath is trimmed with a thin strip of rubber, so you need to be sure the screws get through the rubber to the bares steel. I used a very small flat-head screwdriver to twist through the rubber strip.

And . . . finished, aside from mounting the microphone holder to the side of the transmission tunnel, and ordering a Yaesu external speaker. At last we’ll have a radio suitable for our responsibilities as trip leaders, and great for simply sharing interesting sights along the spine of North America and elsewhere.

*If you own a Toyota or Lexus and live within, say, 400 miles of Farmington, New Mexico, Bill's Toy Shop is worth the trip for major work. He'll also be teaching several mechanics classes at the Overland Expo. billstoyshop.com

A more Affordable aluminum bridging ladder

One of the most basic and effective tools for self-recovery in sand, mud, or snow is what we generically call the sand ladder or sand mat. For decades these typically comprised a cut-down section of WWII surplus PSP (Perforated Steel Planking, also called Marsden matting), originally designed to be linked together to build impromptu runways on boggy ground. Shoved edge on against a tire buried in sand, PSP provides a ramp on which the vehicle can gain traction and climb (especially when combined with some judicious pre-shoveling). PSP is effective but heavy, thus the popularity of a modern version—PAP—made from aluminum.

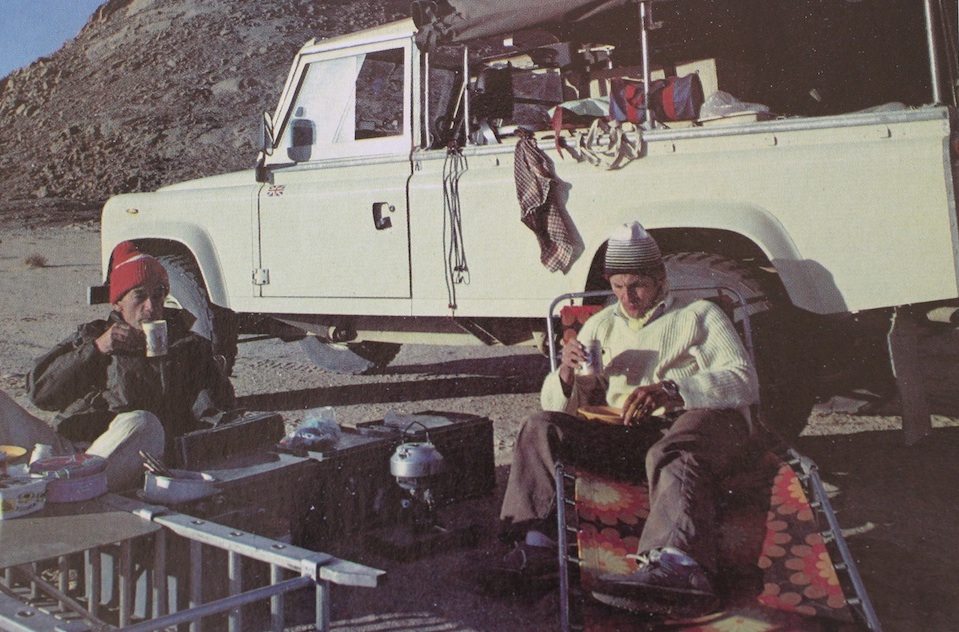

Semi-rigid material such as PSP and PAP works well to provide flotation and traction in soft substrates, but is not stiff enough to be used to bridge a deep ditch, or to function as a ramp to surmount a vertical ledge, unless doubled—in which case the normal complement of two allows only one wheel to be supported. Sahara explorer Tom Sheppard surmounted this problem decades ago by simply ordering a pair of custom-made ladder sections such as one would use at home, but with extra-deep side rails and rungs spaced just 15cm apart. Each section was sturdy enough to provide bridging support for one side of a loaded Land Rover—and with some connecting pieces also served as a convenient framework for kitchen furniture.

Today, plastic sand mats such as the excellent Max Trax offer a lightweight (18 pounds per pair) alternative to traditional versions; however, the Max Trax is still insufficiently rigid to be used as a bridging ladder unless doubled. The connoisseur’s choice for combined traction and bridging duty has for some time been the excellent Mantec bridging ladder (known as a bridgy by the abbreviating Brits), a beautifully trussed and welded structure of aluminum more than strong enough to support a fully laden expedition vehicle. But the Mantec ladders currently run about $650 per pair when you can find them this side of the Pond, and their bulk and weight—42 pounds for the two of them—is a handicap, too.

However, a significantly more affordable ($349) aluminum bridging ladder is on the horizon, thanks to Jeremy Plantinga of the newly formed Crux Offroad. Jeremy contacted me a year ago and showed me a few prototype designs before finalizing a design and shipping me this set—which comes disassembled via UPS, saving yet a bit more in shipping costs (a flat $30 to the lower 48).

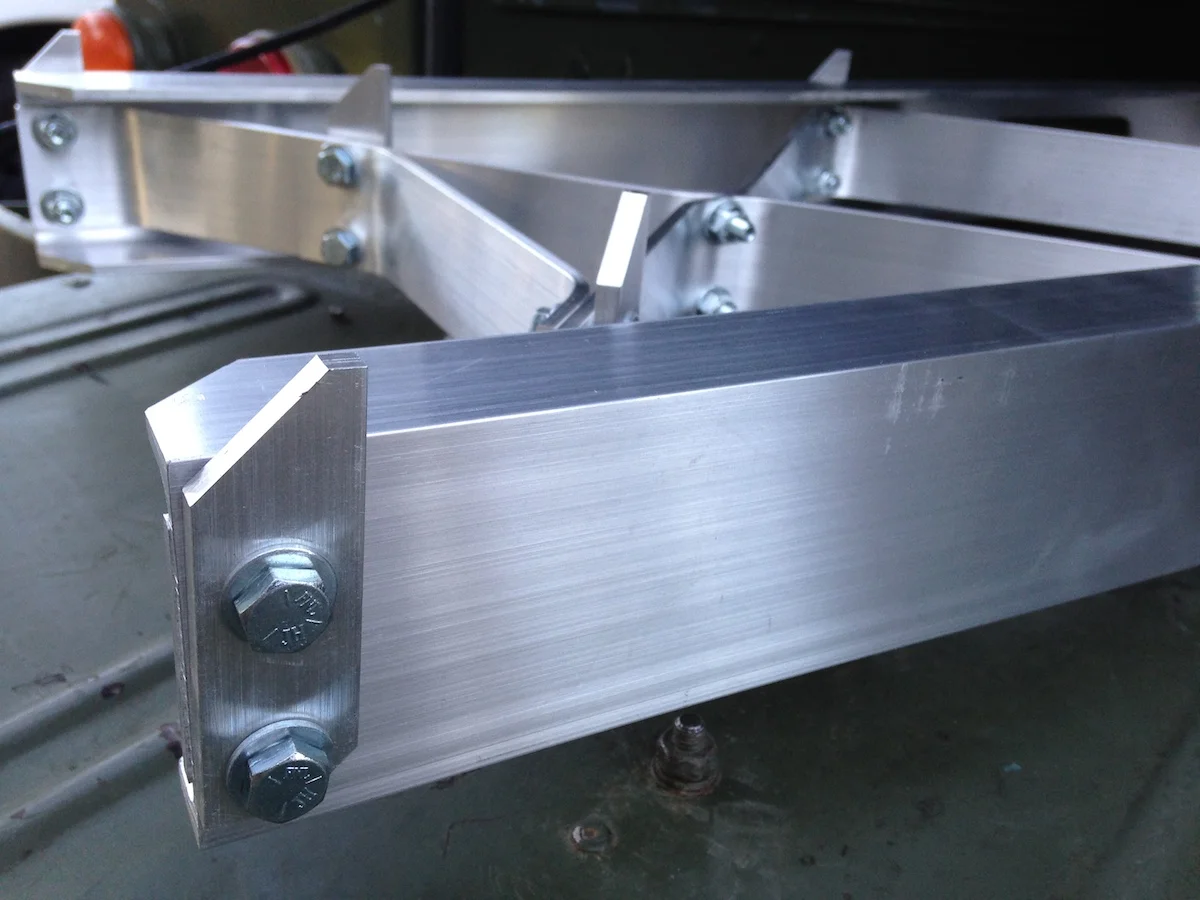

The main structure of the Crux ladder comprises two 48-inch-long U-shaped side channels and two W-shaped cross treads, with a brace at each end and a total of 12 aluminum grip spikes that extend beneath the rails. The ladder is designed so the tire contacts the cross treads only after passing the ends of the side channels, to reduce the chance of kick-up. The instructions say assembly takes about an hour; I did the first one in 25 minutes and the second in 20. The side channels can be assembled with the U either in or out, depending on the width of your tires—with the U facing in the ladders appear more than wide enough for either the 235/85x16 ATs on our Tacoma or the 255/85x16s on the FJ40. The modular design means it will be easy for the company to tweak dimensions for different applications.

Mantec on the left, Crux on the right

In a quick visual comparison the Crux ladder lacks the monolithic support of the Mantec. It's obvious the Crux will offer less flotation in very soft sand, mud, or snow; on the other hand its open cross treads should significantly enhance traction and reduce kick-out when climbing. At 34 pounds per pair the Crux ladders are 20 percent lighter than the Mantecs (although they are also 20 percent shorter). Last year on the Continental Divide, when an FJ Cruiser pulling a trailer got stalled on some uphill ice, a pair of Max Trax we deployed simply zipped right under the tires when power was applied; the plastic offered no purchase against the ice. I’m willing to bet the grip spikes on the Crux ladders will do better in the same situation. For bridging, Jeremy rates the Crux ladders at 2,000 pounds each, which, given the insight I’ve had into his failure testing, seems appropriately conservative, and more than enough to support most full-size pickups, or a Land Cruiser or Jeep Wrangler Unlimited. Jeremy has plans to develop accessories such as table or bench tops and legs, which would enhance their versatility.

I’m looking forward to field-testing the Crux ladders, and expect they’ll perform well. If you’re intrigued too, they will be debuting and available at the Overland Expo in Mormon Lake next month. I plan to hand over my set to the Camel Trophy blokes to see what they can come up with for on-site testing.

The company's nascent website is here.

Update: I've had a little time to play with them. Supporting the front wheels of a Defender 110 in the middle of the span, the Crux ladders showed essentially zero deflection. Impressive . . .

Another update: The Crux ladders nest securely, located by the traction spikes. When joined, the adjacent handle holes make it easy to carry both ladders with one hand.

Hint: When using “Search,” if nothing comes up, reload the page, this usually works. Also, our “Comment” button is on strike thanks to Squarespace, which is proving to be difficult to use! Please email me with comments!

Overland Tech & Travel brings you in-depth overland equipment tests, reviews, news, travel tips, & stories from the best overlanding experts on the planet. Follow or subscribe (below) to keep up to date.

Have a question for Jonathan? Send him an email [click here].

SUBSCRIBE

CLICK HERE to subscribe to Jonathan’s email list; we send once or twice a month, usually Sunday morning for your weekend reading pleasure.

Overland Tech and Travel is curated by Jonathan Hanson, co-founder and former co-owner of the Overland Expo. Jonathan segued from a misspent youth almost directly into a misspent adulthood, cleverly sidestepping any chance of a normal career track or a secure retirement by becoming a freelance writer, working for Outside, National Geographic Adventure, and nearly two dozen other publications. He co-founded Overland Journal in 2007 and was its executive editor until 2011, when he left and sold his shares in the company. His travels encompass explorations on land and sea on six continents, by foot, bicycle, sea kayak, motorcycle, and four-wheel-drive vehicle. He has published a dozen books, several with his wife, Roseann Hanson, gaining several obscure non-cash awards along the way, and is the co-author of the fourth edition of Tom Sheppard's overlanding bible, the Vehicle-dependent Expedition Guide.