Overland Tech and Travel

Advice from the world's

most experienced overlanders

tests, reviews, opinion, and more

Do you want it hard or soft? (your motorcycle luggage, that is)

I equipped this test Royal Enfield with a combination of AndyStrapz canvas panniers, a Wolfman duffel, and a Pelican case rack trunk for a traverse of the Grand Canyon's North Rim

I equipped this test Royal Enfield with a combination of AndyStrapz canvas panniers, a Wolfman duffel, and a Pelican case rack trunk for a traverse of the Grand Canyon's North Rim

Just as our instinctive mental image of an expedition vehicle is more than likely a Land Rover 110 or Land Cruiser Troopie equipped with a roof rack loaded down with jerry cans and sand mats, so our image of an adventure motorcycle is likely to involve a giant BMW GS bulging with several square meters of aluminum sheet artfully folded and welded into rugged panniers and trunks covered with flag stickers from far-off places.

Thousands of the owners of these bikes have actually been to those far-off places. But how many riders chose those aluminum cases based solely on Long Way Round videos and magazine articles? How many remained satisfied with the approach after several thousand miles of travel? How many riders switch to soft luggage later on—and by the same token, how many riders start out with soft luggage and later switch to hard cases? Is there an overwhelming argument in favor of either, or is the choice simply a matter of trade-offs and priorities?

The debate has been the subject of endless forum threads begun by curious and innocent new riders. Replies generally fall into one of two categories: 1) “USE THE SEARCH FUNCTION!” or 2) Fifteen pages of opinions backed by rock-solid logic (and sometimes rock-solid experience) but little nuance. It’s either hard-luggage-is-the-only-way-to-go or soft-luggage-is-the-only-way-to-go.

The basic arguments for each are easily summarized. Soft luggage is less expensive, significantly lighter (with the equally important resultant benefit of a lower center of gravity), and not as likely to injure a foot or leg caught between luggage and ground during a spill or when working though rock gardens or sand. Soft luggage rarely requires special brackets to mount, generally results in a narrower bike profile, and can be compressed even further for shorter trips. If a soft pannier clips a rock or other obstacle during slow-speed maneuvering, it’s less likely to catch and throw the bike off balance.

Hard cases provide much better security from both outright theft and slash-and-grab attacks, are sometimes (but not always) more weatherproof, they sometimes can protect both rider and bike in a spill (as long as the situation described above doesn’t happen, and the luggage or its bracketing doesn’t damage the bike’s frame), and if easily removable can serve as seats or tables. Hard cases are easier to pack, provide better protection for fragile equipment, and can be modified easily with brackets for extra fuel canisters, etc.

Doug Mote's hard cases, ready for "easy going."

Doug Mote's hard cases, ready for "easy going."

Summarizing arguments is easy, but it doesn’t make a choice any easier. What I wondered, and had never seen in any luggage threads except as vague hints, was if there might be a formula that would use easily quantifiable variables specific to the rider to point him or her in the right direction.

My own motorcycle luggage expertise (not counting long ago rides wearing a Camp Trails frame pack, which provided spectacular windage) is limited to the excellent canvas luggage from Andy Strapz, combined with an equally excellent Wolfman duffel, and a Pelican case pressed into service as a security trunk. The combination suited me perfectly, but I wanted to get input from those with far more extensive riding history. So I sent out a poll asking the question: hard or soft, and why? I hoped the results might coalesce into a logical hierarchy that would lead to a simple formula.

Those who shared their experience included Carla King, Tiffany Coates, Lois Pryce, Austin Vince, Doug Mote, Kevan Harder, Nicole Espinosa, Brian DeArmon, and Bruce Douglas. The result comprised what I considered to be a useful cross-section of the long-distance riding community—both sexes, and a mix of body sizes, travel styles, and motorcycle choices (from 250 to 1200 cc).

Indeed, as I began going through the responses from this vast pool of experience, definite trends became apparent. In the end I was able to come up with an algorithm accurate enough that I could plug in variables from almost any of the experienced riders I polled and correctly predict what kind of luggage he or she used in what situation.

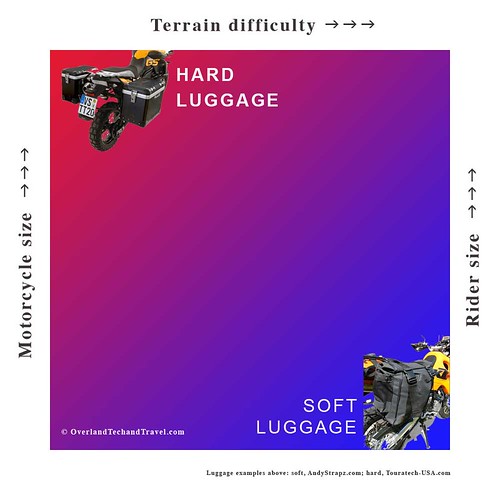

Essentially (aside from your budget), I decided only three variables are necessary to determine which type of luggage will best suit you. While there is some gray area, in general I think most people will find themselves trending one way or the other. The variables are:

- Size of motorcycle

- Size of rider

- Difficulty of terrain

No earth-shaking revelations there, but the relationship between the three can shift things one way or another. The chart shows how the recommended choice shifts from hard (red) to soft (blue), with purple as the could-go-either-way middle ground.

Simply explained, if you’re a big rider on a big bike and stick to asphalt or fairly well-maintained dirt roads, the advantages of hard luggage will most likely outweigh its disadvantages. Conversely, a small rider on a small bike who frequently challenges technically difficult routes would almost certainly be better off with soft luggage.

Some ambiguity arises if we start mixing and matching variables, but the observations of our experts still tilt the smart choice one way or the other. For example, small bikes—say under 650 cc—have a harder time coping with the weight and windage of hard luggage, regardless of terrain. Similarly, a big rider on a big bike who finds himself in central Africa during the rains, or deep in Egypt’s sand seas, or even on three-plus-rated 4x4 trails in the American West, will still benefit from the lighter weight, lower CG, and forgiving impact absorption of soft luggage.

As filmmaker Sterling Noren recently found out, even anodized aluminum cases aren't impregnable

As filmmaker Sterling Noren recently found out, even anodized aluminum cases aren't impregnable

There’s also one more option to be considered regarding hard cases: While the Ewan-endorsed, steamer-trunk-sized aluminum cases represent the paradigm of hard luggage, lighter and smaller plastic cases, such as those offered by BMW for the F 650 GS, represent a viable middle ground in price, weight, and windage (and security). Another increasingly popular approach is to mount a small hard case such as a Pelican as a rack trunk, to provide security for cameras, laptops, and such, and go with soft cases for the rest of the luggage.

Here are some of the comments from our panel of experts, who collectively total a couple of million miles of motorcycle travel, including four circumnavigations.

Carla King’s motorcycle adventures began in 1995 with a 10,000-mile circumnavigation of the U.S. on a Ural with a sidecar, and haven’t stopped since. You can order the delightful book documenting the trip, along with her other published works, from her website here. Carla wrote, “Right now I’m setting up a new-to-me KLR, for which farkle options are famously infinite. After much research into cost, durability, security, convenience, and safety, I chose the Giant Loop soft luggage. Seems I can throw it on any bike, stuff almost any size and shape of thing into it, check it as luggage, and perhaps most importantly it’s not going to crunch my bones when I ride beyond my skill level and fall on (insert hard object here).”

Tiffany Coates set off on her first motorcycle trip, from the U.K. to India, with two months of riding experience. She has a bit more now—over 200,000 miles worth and counting, including the riding she did while filming a BMW unscripted commercial on Thelma, her much loved and well-used BMW R80GS. Tiffany still nurses the factory plastic cases that came on the bike, the latches of one of which long ago gave up trying to hold in the contents (small wonder - see photo below). According to her, “For me, the BMW plastic cases are ideal. Perfect size, with the ‘suitcase compression’ system which means I cram everything in and then sit on it (or two of us if we’re two up). Apparently we get more in these cases than the large metal ones due to the compression. Cheaper and lighter than metal cases and smaller—no risk of getting a leg caught under them if there is a fall. Also ultra-easy to unlock and whisk off the rack ready to carry into a hostel, or for emergency unloading in a river fall! As they are hard cases they are secure as well. I’m not anti-soft luggage, I have just never used it as the BMW panniers were on Thelma when I got her and so I never had a decision to make about what luggage to use.” Find out where Tiffany is now here.

Tiffany and a friend do a little cargo compacting

Tiffany and a friend do a little cargo compacting

Lois Pryce couldn’t seem to exorcise the motorcycle travel bug by riding a 225 cc Suzuki from Alaska to Tierra del Fuego. So she traded up to a much bigger bike (250 cc) and rode from her home in England to Cape Town (two excellent books here). As she was on tour in the Netherlands with her bluegrass band, the Jolenes, when I emailed her, her reply was short but thorough: “I prefer soft luggage: lighter, less ostentatious, no need for a rack, easy to lift on and off, easy to repair, and cheaper to buy. AndyStrapz panniers are the best.” (Want to hear the Jolenes? Go here. Lois is the banjo player.)

Austin Vince’s main claim to fame is that he’s married to Lois Pryce. Oh, well . . . he’s also ridden a Suzuki DR350 around the world. Twice. And made a rousing film of each trip. Austin is the antidote to anyone who tells you you need a $20,000 motorcycle and a further $5,000 in kit to do any serious adventuring. His riding suit is a pair of mechanics’ coveralls. His goggles appear to be Audrey Hepburn’s castoff sunglasses from Breakfast at Tiffany’s. Tent? A surplus shelter half. Luggage? I’ll let Austin explain.

“Soft. Here’s why:

1) Looks cooler and less aggressive compared with armoured-car-ish aluminum boxes. I really do think this is important when travelling amongst poorer societies.

2) Easily personalized and created from government surplus stores, etc. If your luggage is improvised then you are richer in terms of investment in your project. My current ALICE pack system has two major bags of 40 litres each, and 12 separate mini pouchlets of varying smaller volumes, all super-useful: Oil, rags, toilet paper, sun cream, water, etc. is all instantly accessible without undoing a single flap. Total cost, $35 U.S. No manufacturer can match this.

3) Safety. No one has broken a leg on a soft pannier.

4) Luggage is easily repaired and conversely, if it gets damaged, it only cost $35 so who cares?

5) All my DIY luggage is zero waterproof so I simply put my gear in a $5 waterproof liner therein—it’s so simple I want to cry.

6) Hard luggage makes the bike physically massive and far too unwieldy.

7) Jonathan, I love you (call me—like the old times).”

(Editor’s note: I take no responsibility for number 7. Just passing it on in the interest of full disclosure.)

Austin Vince's $35 pannier system (courtesy U.S. government surplus)

Austin Vince's $35 pannier system (courtesy U.S. government surplus)

Brian DeArmon is the thinking rider’s rider. Every equipment choice he makes is the result of not just long experience as a motorcyclist, but extensive research into pros and cons, competing brands, and above all, quality. Generally when Brian adds something to one of his bikes, that’s the last you hear about it, because it works. Given all that, it was no surprise that his detailed response more or less summarized my conclusions before I even reached any.

“Short version: Bigger bikes that are being used on easy to moderate terrain, with predictable weather conditions, I tend to favor hard bags (primarily for the security and ease of access). For small bikes, or any bike going where trail conditions are unknown, I prefer soft bags.

Long version:

Suspension: It’s too easy to overload a small bike already. Add in 15 or 20 pounds for the hard panniers and mounting brackets, you eat into valuable capacity. The big bikes are better able to handle those loads. Unfortunately, hard panniers also make it real easy to strap even more crap on the bike since they typically create a nice big surface area & include those nice tie down points.

Power: Smaller bikes typically don't have the power to push big loads down the road at the speeds required in the west. I've ridden the DR200 on the freeway with no load, and it’s kinda scary, even in the slow lane. I couldn't imagine doing it with an extra 40 pounds of pannier/gear/food/water (state highways and back roads, sure, just not freeways where traffic is moving 70 to 80 mph). Put that load on a GSA or big KTM and you don't have the same problem.

Trail conditions: On relatively tame roads, in known weather conditions, hard panniers are not much of a liability, IMO. The risk of crashing isn't that high. But once conditions become unknown, or weather conditions make a turn towards the wet side (mud), hard panniers become a huge liability. There is the obvious danger of tib/fib breaks, but also damage to the bike itself. My GS has a bent subframe caused by smacking a pannier on a rock. That is hardly a concern with soft bags.

Security and Convenience: Hard bags have a hands-down advantage for security and ease of use. Dump in your gear, close the lid, lock the latch, and you’re done. They’re typically easy to dismount and move into a hotel room, etc. Soft bags often have a convoluted mess of straps that makes it more difficult to access gear and install or remove. Soft bags also need to be checked regularly as loads change and straps loosen. Of course there is also the problem of having nothing between your gear and a thief but a knife.

Basically, I see soft bags as the default luggage system, with hard bags being a legitimate option if certain conditions are met.”

Nicole Espinosa didn’t like the racks available for the Suzukis she rides, so she made her own. Now she runs a business, Rugged Rider, which specializes in high-quality accessories for the reliable and overachieving small DRZs. Nicole wrote: “I feel the DRZ400 is the perfect bike to set up for adventure. It has a strong enough engine to maintain a comfortable 70 MPH on the highway, and is a nimble enough size to have fun on tight single-track fully loaded. That said, I prefer soft luggage for a tighter profile on highway against wind, and on trails for width. I only keep my clothes and rain gear in my Ortleib dry side bags, and have only traveled in North America as of yet, so I haven’t put the security of soft bags to the test internationally. I keep my expensive gear in my tank bag that I can carry with me or ratchet down on my locking combo luggage rack.”

All you need to know about Doug Mote as a rider is summed up below in his reference to “easy going.” Anything else I’d add would be superfluous, except to say he’s one of the nicest guys I know (despite his comment about kicking KTM ass). As a lumberjack and body double for Paul Bunyan, Doug was at the far end of my bell curve for big riders with big bikes. He sent: “I have hard and soft luggage, and use both. My preference depends on itinerary. For easy going, like say a run to Prudhoe Bay on a schedule, hard bags offer several advantages, not the least of which is better weather protection. On this type of good road trip in wide open spaces, there is little risk of leg or foot injury such as I have witnessed friends incurring when trapped between bag and earth. For tough going, where lightness and flexibility are key, soft luggage is superior. Spills are not so risky, and my entire kit weighs less than empty hard bags with mounting racks. I use only soft bags on the 650, either soft or hard with the 1150 depending on the route and how much KTM ass there is to kick. For extended travel with diverse route conditions, soft luggage is my clear choice."

I won’t claim that Bruce Douglas sometimes uncovers a motorcycle in his yard he’s forgotten he owns, but he does own a lot of them, and has based his transportation on motorcycles since his very first vehicle, a two-stroke Yamaha 360. His main backroad bike is a thoughtfully modified Suzuki DR650. Bruce wrote: “I’d say hard cases for security, appearance, and good mounting surface for other stuff. I think they’d be fine if I knew I wouldn’t be riding through any difficult terrain, but if there was a chance I might go down I’d have to go with soft bags. A few times when I’ve put my foot down while moving on the TransAlp I had it get caught under the hard case. It was clear how easily you could break something—and it wouldn’t be the case. I think I’m sold on soft bags now after the Baja trip. I like their versatility; I can use different bags with my mounts, since the main function of most mounts is to keep the bags away from the rear wheel. I’m happy with what I have, they’re simple and straight forward. The Wolfman Gen 2 mounts are interesting: a little complicated but they add more mounting points, and a means to carry extra fuel. Also knowing I can repair them with a sail needle and thread is nice. In a spill they flex, rather than dent. If the mounting straps tear off you can come up with a repair, or just tie it on with cord. The chance of the mounts coming out of hard cases is slim, but if they did, a field repair would be difficult. Soft bags aren’t as secure, but after undoing a few straps you can pull them off as saddle bags and carry them over your shoulder (a la John Wayne). In Baja I was able to carry all my gear in one trip: saddle bags on my shoulder, the tail bag in one hand, and whatever in the other hand. Soft bags also make you think about packing and not be tempted to just dump stuff into metal boxes.”

And finally, from Kevan Harder, a California police and SWAT officer who also works for RawHyde Adventures, where it often seems motorcycles are defined as BMW or . . . everything else . . . comes a firm vote for the red corner of the chart: “I strongly recommend hard bags for durability, protection of gear, and versatility (bike service stand, chair, table, etc).”

So there you have it, courtesy of some of the most experienced riders on the planet: an easy way to determine what type of motorcycle luggage will best suit you, your bike, and your riding.

Think this will end all those forum debates?

Ditch the cigarette lighter

On the left, cigarette-lighter outlet: plastic body and lock ring, guaranteed-to-break rubber cover "hinge," press-fit back plate. On the right, German-made DIN receptacle: metal body, brass lock ring, rigid cover with spring-loaded hinge. The cordless automotive cigarette lighter was patented 90 years ago, and assumed its present configuration in 1956. I know for a fact that by 1960, car campers already had a range of 12-volt appliances from which to choose, such as the Boilmaster Junior Compact Kitchen coffee percolator featured in my old copy of The Ford Treasury of Station Wagon Living.

On the left, cigarette-lighter outlet: plastic body and lock ring, guaranteed-to-break rubber cover "hinge," press-fit back plate. On the right, German-made DIN receptacle: metal body, brass lock ring, rigid cover with spring-loaded hinge. The cordless automotive cigarette lighter was patented 90 years ago, and assumed its present configuration in 1956. I know for a fact that by 1960, car campers already had a range of 12-volt appliances from which to choose, such as the Boilmaster Junior Compact Kitchen coffee percolator featured in my old copy of The Ford Treasury of Station Wagon Living.

That means that for five decades those wishing to use their vehicles’ cigarette lighters for anything besides igniting a Pall Mall have put up with the “UL Standard 2089” 12-volt plug to try to get DC power to their portable percolators, tire pumps, GPS units, inverters—even their National Luna 74-liter double-door fridge-freezers.

Are we really that submissive to the dominant paradigm? If GM reintroduced front drum brakes and two-speed automatic transmissions would we all go, “Well . . . okay!” We’re talking the same era here.

Anyone who has ever used a standard auto lighter receptacle as a power outlet knows they’re garbage for that application. It’s impossible to tell when the positive post in the center of the male plug makes contact with the positive tab at the back of the female unit, and—especially if your appliance’s plug doesn’t have a spring-loaded post, or if the spring has seized, as most do after about two months of use—contact can be lost with no warning except when you stop for a cold Coke three hours later and find only tepid Cokes in the fridge. Worse, the most common aftermarket cigarette-lighter-type “power outlets,” which many of us install to run extra equipment, are constructed with a plastic back plate for the positive contact that is a simple press fit into the plastic body. Push too hard on the plug and the whole back end of the receptacle pops off.

There’s a better way, and by this time European readers and a lot of American BMW GS riders will be nodding their heads knowingly. They’ve been happily using the DIN (Deutsches Insitut für Normung) 12-volt plug system for years. The DIN plug, while more compact than the cigarette lighter (11/16-inch mounting hole versus one and a quarter) is significantly more rigid and wobble-free. The dash (female) socket grips the positive post of the plug with spring-loaded fingers—push in the plug and it snaps home with an authoritative click. No risk of pushing too hard, no risk of accidental disconnection, even on the roughest roads.

After years of muttering and cursing, and a brief consulation with my friend Brian DeArmon, I finally made the switch, courtesy of our local BMW motorcycle dealer in Tucson, Iron Horse. It’s easy to do, although if you want to install a DIN outlet in a hole made for a cigarette lighter you’ll need to buy or fab a thin washer to reduce its diameter. On the dash of my FJ40 I decided to leave the old receptacle in place so I wouldn’t have to use an adapter when borrowing or testing appliances equipped with that plug. I had a perfect place just below the old receptacle to install a DIN unit, where my stock dome-light switch was located. Since I use a Hella map light for a dome light now I had no need for the switch, so I simply enlarged the hole and installed the DIN receptacle. For now I just siamesed the wires to both receptacles and use a single fuse, since I never run two heavy-draw appliances from the dash at the same time.

FJ40 dash with cigarette-lighter outlet, stock dome light switch underneath.

FJ40 dash with cigarette-lighter outlet, stock dome light switch underneath. DIN receptacle in place, wired in parallel.

DIN receptacle in place, wired in parallel.

If you don’t have a BMW dealer nearby, you can get DIN plugs and accessories from a company called Powerlet. The standard socket is part #PSO-001, and there is a selection of plugs, including a nifty low-profile right-angle version. They even have a pretty decent-looking cigarette-lighter plug if you’re a fan of two-speed transmissions, or would like to leave one standard socket in the vehicle as I did.

Swapping plugs on your old appliances is easy, too. Some 12V fridges come with convertible plugs; a red spacer allows use with a cigarette lighter; remove the spacer for a DIN receptacle. It works okay, but switching to a DIN-only plug is more compact and stronger.

Straight and right-angle DIN plugs are available.As with many such simple and effective modifications, my only regret has been, why did I wait so long?

Straight and right-angle DIN plugs are available.As with many such simple and effective modifications, my only regret has been, why did I wait so long?

Speed vs. economy, or Fd = 1/2pv(squared) x CdA

Diesel engines such as this fine 1HZ are inherently economical, but they still have to work harder to push a vehicle faster Fuel economy is a funny subject. Very, very few people want to admit their vehicles get poor mileage. The overwhelming tendency is to fudge the other way when the subject comes up. I know for a fact there are guys who get 25 miles per gallon at 75 miles per hour in their one-ton diesel pickups while towing their 30-foot Airstream trailers, because I hear it with astonishing frequency.

Diesel engines such as this fine 1HZ are inherently economical, but they still have to work harder to push a vehicle faster Fuel economy is a funny subject. Very, very few people want to admit their vehicles get poor mileage. The overwhelming tendency is to fudge the other way when the subject comes up. I know for a fact there are guys who get 25 miles per gallon at 75 miles per hour in their one-ton diesel pickups while towing their 30-foot Airstream trailers, because I hear it with astonishing frequency.

I also know they don’t.

I never say as much when presented with these or similar absurd boasts, because there’s simply no profit in doing so. All I do is raise my eyebrows and say, subtly, “Wow. That would be impressive.” To show skepticism, much less outright derision, provokes the same peculiar outrage one receives doubting someone who claims to have been abducted and studied by aliens. There’s just no point in arguing.

There’s also no point in arguing with the laws of physics—especially those relating to speed. Note that formula in the headline. In plain English it states that the drag (Fd) on a solid object moving through a fluid medium (which in physics includes air) is a function of one-half the density (p) of the medium times the speed (v) of the object, squared, times the drag coefficient (Cd) of the object times its cross sectional area (A).

Note in particular the reference to the square of speed. That means that as speed goes up, the drag that results rises on a logarithmic curve. If speed doubles, drag quadruples.

Diesel engines such as this fine 1HZ are inherently economical, but they still have to work harder to push a vehicle faster Fuel economy is a funny subject. Very, very few people want to admit their vehicles get poor mileage. The overwhelming tendency is to fudge the other way when the subject comes up. I know for a fact there are guys who get 25 miles per gallon at 75 miles per hour in their one-ton diesel pickups while towing their 30-foot Airstream trailers, because I hear it with astonishing frequency.

Diesel engines such as this fine 1HZ are inherently economical, but they still have to work harder to push a vehicle faster Fuel economy is a funny subject. Very, very few people want to admit their vehicles get poor mileage. The overwhelming tendency is to fudge the other way when the subject comes up. I know for a fact there are guys who get 25 miles per gallon at 75 miles per hour in their one-ton diesel pickups while towing their 30-foot Airstream trailers, because I hear it with astonishing frequency.

I also know they don’t.

I never say as much when presented with these or similar absurd boasts, because there’s simply no profit in doing so. All I do is raise my eyebrows and say, subtly, “Wow. That would be impressive.” To show skepticism, much less outright derision, provokes the same peculiar outrage one receives doubting someone who claims to have been abducted and studied by aliens. There’s just no point in arguing.

There’s also no point in arguing with the laws of physics—especially those relating to speed. Note that formula in the headline. In plain English it states that the drag (Fd) on a solid object moving through a fluid medium (which in physics includes air) is a function of one-half the density (p) of the medium times the speed (v) of the object, squared, times the drag coefficient (Cd) of the object times its cross sectional area (A).

Note in particular the reference to the square of speed. That means that as speed goes up, the drag that results rises on a logarithmic curve. If speed doubles, drag quadruples.

Here’s an example using an algorithm I found recently, calculated around a theoretical but representative vehicle with a drag coefficient of .30 (very low), and a frontal area of 30 square feet, on a paved road. Our vehicle requires just 2.6 horsepower to move at 20 mph. To reach 40 mph it needs 8.2 horsepower, and to reach 60 it needs 19.6. To cruise at 80 would require 39.9 horsepower—twice that needed to maintain 60. (To give you an idea of the drag acting on very high-performance sports cars, our vehicle would need 521 horsepower to hit 200 miles per hour.) The unassailable fact of highway driving is that beyond about 40 miles per hour aerodynamic drag overtakes powertrain friction and rolling resistance as the chief factor in fuel consumption—and from there on up it wages a rapidly escalating war on the level in your tank.

Another . . . interesting . . . claim I’ve heard is from guys (mileage fudging seems to be strictly a male pastime) who say something like, “I get better mileage at 80 than at 60 because my engine is in its power band there.” Sorry, but nonsense. There might be situations in which, say, shifting from fourth gear at 55 mph into an overdrive fifth gear and adding a few miles per hour will do no harm to or perhaps even slightly improve economy, but for a given gear, adding speed will increase fuel consumption, plain and simple. No one is going to get better gas mileage at 80 than at 60.

Algorithms are all well and good, but accurate real-world figures are more difficult to locate. Fortunately one of my best friends, Michael Cox, is diligent about recording the mileage he achieves with his 2006 4WD Dodge 2500 pickup, which has the Cummins turbodiesel, a six-speed manual transmission, and BFG All-Terrain tires. He can just break 21 mpg at 55 miles per hour. At 60 it drops to 19.5, at 65 it’s down to 18, and 70 mph knocks off another mile per gallon. He recorded similar changes with his Four Wheel Camper on the truck: 18.5 mpg at 60 mph, 16.5 at 65, and 15.5 or less at 70.

The immediate lesson from all this is so obvious I won’t bother to state it. But more subtle contributors to drag are worth investigating. Cleaning up the aerodynamics of a vehicle can have a significant effect on fuel economy, even on one with the base Cd of an apartment building. Removing the tall porthole ConFerr roof rack on my FJ40 increased my highway (i.e. 60 mph) fuel economy by a full one mile per gallon—and going from 16 mpg to 17 in an FJ40 is a blessing. Suspension lifts and wider tires increase drag, the former hugely. So, somewhat surprisingly, do such add-ons as bull bars and driving lights, which create a dirty front of turbulence before the air even hits the vehicle proper. Extreme example: When my nephew Jake exploited his newfound skills at welding and fabricated an exoskeleton roll cage for his V6 Tacoma, his mileage plummeted from 18 to 13 mpg. So, do you really need a fat grille bar to fend off stray kangaroos, or would you be served with a simple winch bumper? Do you need that Paris/Dakar-esque bank of driving lights, or would a headlamp upgrade provide all the safe illumination necessary? With gasoline poised to top $4.00 per gallon and diesel above that as I write this, every bit will help on a long highway trip.

Ditching the roof rack helps. Brush guard and lights might not hurt the “aerodynamics” of an FJ40, but they can on a more streamlined vehicle.Although rolling resistance becomes less important than aerodynamic drag at high speeds, it’s still worth considering. That one mile per gallon I gained on my FJ40 made up for the exact same amount I lost when I switched from BFG All-Terrains to BFG Mud-Terrains on that vehicle. Long experience with various tread types has led me to the conclusion that there’s not a big mileage difference between street/trail tread patterns such as BFG’s Rugged Terrain and the slightly more aggressive All-Terrain—but jumping to a Mud-Terrain you’ll take a quantifiable hit. So if you put mud-pattern tires on your vehicle just because you like the look, think again. You’ll get better mileage, better handling, a better ride, and longer tread life with an all-terrain pattern, probably equivalent traction in most circumstances, and better in some.

Ditching the roof rack helps. Brush guard and lights might not hurt the “aerodynamics” of an FJ40, but they can on a more streamlined vehicle.Although rolling resistance becomes less important than aerodynamic drag at high speeds, it’s still worth considering. That one mile per gallon I gained on my FJ40 made up for the exact same amount I lost when I switched from BFG All-Terrains to BFG Mud-Terrains on that vehicle. Long experience with various tread types has led me to the conclusion that there’s not a big mileage difference between street/trail tread patterns such as BFG’s Rugged Terrain and the slightly more aggressive All-Terrain—but jumping to a Mud-Terrain you’ll take a quantifiable hit. So if you put mud-pattern tires on your vehicle just because you like the look, think again. You’ll get better mileage, better handling, a better ride, and longer tread life with an all-terrain pattern, probably equivalent traction in most circumstances, and better in some.

What about tire width? Wider tires certainly increase frontal area and drag, but I’ve never seen an authoritative study to determine if a wide but short contact patch produces more rolling resistance than a longer, narrower one. You’d need to determine loading per square inch, hysteresis of the carcass, heat buildup, and other factors to make a solid judgement. With that said, I believe narrower tires offer advantages in so many other areas that I invariably stick with unfashionably skinny sizes. I just spent two weeks in Egypt’s sand seas in gargantuan Land Cruiser Troopies riding on pizza-cutter 235/85x16 All-Terrains, and we were never more than nominally stuck despite running near-street pressure in areas mined with the razor-sharp limestone outcroppings called kharafish.

Narrow tires reduce frontal area and possibly rolling resistance, and they work just fine in sand if aired down properlyThe unique characteristics of individual vehicles can make a difference in fuel economy as well. For example, my mechanic friend Bill Lee had a customer who drove an FJ60 with a five-speed conversion, who complained of wildly varying mileage on the highway in the 60-65 mph range. Bill figured out that the secondary venturi on the 2F engine’s two-barrel carburetor started opening at around 63 miles per hour. If the driver kept the speed just below that, mileage was a full two or three miles per gallon better than just above it.

Narrow tires reduce frontal area and possibly rolling resistance, and they work just fine in sand if aired down properlyThe unique characteristics of individual vehicles can make a difference in fuel economy as well. For example, my mechanic friend Bill Lee had a customer who drove an FJ60 with a five-speed conversion, who complained of wildly varying mileage on the highway in the 60-65 mph range. Bill figured out that the secondary venturi on the 2F engine’s two-barrel carburetor started opening at around 63 miles per hour. If the driver kept the speed just below that, mileage was a full two or three miles per gallon better than just above it.

Modern fuel-injected engines are unlikely to have such a sharp break in efficiency. Nevertheless, it’s worth experimenting with varying speeds—especially if you have a mileage function on your vehicle’s computer—to see if it has a “sweet spot” above which consumption spikes.

In general though, you can expect your computer to tell you, “Yep—when you drive faster you use more fuel, stupid.”

Is Gross Vehicle Weight Rating . . . Overrated?

We all know most of America is overweight these days. But 2,000 pounds overweight?

Scott Lesak wrote us regarding his 1997 Mitsubishi Montero (the one in front here), which he has outfitted extensively for overland travel (his brother Mark owns the one following). Recently, Scott weighed virtually every piece of gear that goes into the Montero for a typical camping trip, and after adding in the curb weight of the vehicle, plus occupants, was concerned, if not really surprised, to find the total nearly 2,000 pounds higher than the factory’s listed 5,700-pound GVWR (Gross Vehicle Weight Rating includes empty vehicle weight plus all fluids, occupants, and cargo). He wondered if by carrying that much excess weight he was, a) risking damage to the vehicle, and, b) compromising safety on the road through reduced braking performance, etc.

To which, of course, the short answer is yes and yes.

We all know most of America is overweight these days. But 2,000 pounds overweight?

Scott Lesak wrote us regarding his 1997 Mitsubishi Montero (the one in front here), which he has outfitted extensively for overland travel (his brother Mark owns the one following). Recently, Scott weighed virtually every piece of gear that goes into the Montero for a typical camping trip, and after adding in the curb weight of the vehicle, plus occupants, was concerned, if not really surprised, to find the total nearly 2,000 pounds higher than the factory’s listed 5,700-pound GVWR (Gross Vehicle Weight Rating includes empty vehicle weight plus all fluids, occupants, and cargo). He wondered if by carrying that much excess weight he was, a) risking damage to the vehicle, and, b) compromising safety on the road through reduced braking performance, etc.

To which, of course, the short answer is yes and yes.

If you’ve never weighed your own vehicle completely kitted and fitted for an overlanding trip, you might wonder how anyone could wind up a ton over the maximum recommended weight for a sturdy 4WD vehicle such as a second-generation Montero (which has a 1,300-pound cargo capacity including occupants). Trust me, it’s not that difficult. In many cases, the weight of just the modifications we bolt to our vehicles can come perilously close to topping the GVWR, before a single down sleeping bag gets tossed in the back. Look at Scott’s list of his own modifications:

150 lbs for upgrade to 35-inch tires

150 lbs for (empty) Garvin 84-inch roof rack

300 lbs for ARB bumper and 12,000-lb MM winch

200 lbs for custom rear bumper and swing-out mount

100 lbs for custom skids under transmission & transfer case

60 lbs for 15-gallon (empty) auxiliary fuel tank

100 lbs for rock sliders

80 lbs for extra AGM battery (105 amp hour; big and heavy for a 2nd battery)

100 lbs for custom drawer system (empty)

20 lbs for ExtremeAir compressor

50 lbs for fridge slide

80 lbs for Engel 60 freezer fridge (empty)

45 lbs for cargo barrier

25 lbs for 84-inch roll out awning

35 lbs for Hi-Lift Extreme jack

Remember that 1,300 pound cargo rating for the Montero? Scott just blew past that by almost 200 pounds—and he hasn’t loaded a single item of camping gear. Or fuel. Or himself. Let’s look at the rest of his list.

200 lbs for 25 gallons non-potable water for showering/cleaning

80 lbs for two 5-gallon jerry cans of potable water

92 lbs for 15 gallons fuel in auxiliary fuel tank

123 lbs for fuel in main tank

60 lbs clothing for 4 persons for 5 days

30 lbs for storage box #1 containing propane grill/heater and various accessories

40 lbs for storage box #2 containing cookware, electric coffee pot, dry food items

40 lbs for 4 sleeping bags, towels, pillows

20 lbs for 4 folding chairs

20 lbs for tent/awning mosquito net/folding table

20 lbs for firewood

10 lbs for propane tank

5 lbs for axe/sledge

700 lbs for passengers

40 lbs for hiking pack

60 lbs for gear in drawer (hoses for shower system, chains, recovery straps, 1 qt engine oil, 1 qt trans fluid, Hi-Lift attachments, basic tools, air hoses for tires/air mattress, lantern, fire ring, 1200 watt inverter)

20 lbs food/drink in the fridge

10 lbs cold weather clothing/rain gear suits

That’s another 1,570 pounds of people and stuff. And while it’s certainly comprehensive, there’s nothing in the entire list that’s really out of the ordinary for a vehicle set up for backroad exploration and camping with a family in mind. But what about unforeseen consequences from all that weight?

Every vehicle has a GVWR, or Gross Vehicle Weight Rating, specified by the manufacturer. The information is usually on a sticker on the edge of the driver’s door or door frame, as well as in the owner’s manual. There are dozens of factors that can be used to calculate GVWR, which isn’t to say that all manufacturers use the same list. Most obvious is the suspension, including spring rates, shock valving, anti-roll bars, etc. Braking capacity is another critical variable. Chassis design, wheel and tire size and rating, engine horsepower and torque, transmission capacity, differential gear size and ratio, driveshafts, axles, wheel bearings, CV joints—all these and more contribute in some way to the vehicle’s capacity to haul a load. Whether or not they’re all included by the manufacturer, they should be considered as an interdependent system by the owner.

You might think fear of litigation would drive manufacturers to be conservative regarding GVWR, but, particularly when discussing pickup trucks, advertising trumps reality. If your pickup has an 8,000-pound GVWR, and the brand across the street boasts a 8,500-pound GVWR, that makes your truck look puny in the one-upmanship game with which the American truck market is obsessed. So just because your vehicle is rated to carry 2,000 pounds of cargo doesn’t mean it can do it comfortably—or even safely. As an example, our 2000 Toyota Tacoma Extra Cab with the TRD package was rated to carry 1,400 pounds, if memory serves. Yet with nothing but an 800-pound Four Wheel Camper in the bed the rear end sagged alarmingly, the headlights lit up bedrooms in third-floor apartments, and we negotiated corners looking like a sailboat rounding a leeward buoy. Immediate suspension modification was called for. In our case, a set of heavy-duty shock absorbers and a pair of adjustable air bags handled the situation perfectly.

Scott’s Montero is equipped with a set of custom coil springs, and from photographs they appear to handle the extra load very well. The factory shocks that came on the vehicle are adjustable, and now live permanently in the “firm” mode (brother Mark’s Montero didn’t have that option and rides on Old Man Emu shocks).

Scott also extensively modified the vehicle for better performance on challenging trails. The tires are 35-inch Goodyear Wranglers, significantly taller (and heavier, as noted in his list) than the stock 30-inch tires. To fit them, Scott raised the suspension two inches and installed a two-inch body lift as well. He compensated for the taller tires by changing the differential gears from 4.2/1 to 4.9/1. In addition, the modest stock transfer case ratio of 1.9:1 is now a healthy 3.15:1, giving the Montero a very good 43:1 crawl ratio in 1st/low. The vehicle also has a stock Mitsubishi rear diff lock and an ARB front locker.

On Class 3 and 4 trails, there’s very little doubt Scott’s Montero would outperform a stock one. But how do his modifications, combined with the oversized load, affect its durability and safety as an overland vehicle?

The springs are clearly doing their job keeping the vehicle level and retaining sufficient suspension travel. The next component to consider is the braking system. Scott is lucky in that his Montero came with four-wheel disc brakes, not very common on mid-90s SUVs. Nevertheless, at nearly a ton over GVWR those discs are obviously working harder than they would be in a lightly loaded truck, and there’s no need for a track test to confidently assume emergency stopping distances are increased. And the bigger tires don’t help at all, as they add an enormous amount of rotating mass. I have a study in hand from the American Association of Motor Vehicle Administrators, in which they tested braking effectiveness with successively larger tires on a 1992 F150 Ford standard-cab pickup, in terms of the g-force generated by specific pressure on the brake pedal. For example, 76 pounds of pedal pressure—equivalent to a hard stop—produced .57g of retardation with 32-inch tires, but only .51g with 35-inch tires. With 150 pounds of pedal pressure—a full panic stop—they recorded .68g with the 32-inch tires, and only .62g with 35-inch tires. Since Scott’s Montero’s stock tires were 30-inchers, we might expect the difference to be larger in his case. In addition, the weight of the roof rack and its contents puts more stress on the front brakes in a panic stop, and will kick in the Montero’s rear anti-lock system earlier.

Those larger tires, combined with the suspension and body lift and the loaded roof rack, also negatively affect the center of gravity of the vehicle. In the same study referenced above, the Ford truck was evaluated for Static Stability Factor (SSF), an industry standard for determining the vehicle’s chances of rolling during a violent emergency maneuver. On stock 29-inch tires with no suspension modifications, the chances of rolling were calculated at 10 to 20 percent—low enough to earn the truck a four-star rating (out of a possible five). On 35-inch tires, with a three-inch body lift and a four-inch suspension lift—not at all out of the ordinary on a full-size truck—the chances of rolling went up to 30 to 40 percent, enough to drop it to a two-star rating. And that’s without a loaded roof rack. (I doubt any of this is a revelation to Scott, but I found it interesting to see actual figures attached to what we know instinctively.)

I got a dramatic seat-of-the-pants lesson in the effect a loaded roof rack can have on a trip to Mexico in my FJ40 (with its short 90-inch wheelbase and tall profile), when I rashly decided to carry an uninflated 14-foot Zodiac and a 40-horsepower Yamaha outboard up top. Total weight, including the massive Con-Ferr rack, about 600 pounds. All went reasonably well on the curvy road to Hermosillo—until I had to dodge a cow that stepped into my lane: Oh. ooh. C’mon. Jeeeez.

Back on four wheels, I thought calmly to myself, Right. Last trip with a powerboat on the roof.

Looking at the rest of Scott’s modifications, the 4.9 ring and pinion gears he installed are weaker than the stock 4.2 gears, due to the smaller pinion needed to achieve the higher ratio. Combined with the 35-inch tires this compromises the drivetrain strength. However, the second-generation Monteros came with mighty 9.5-inch rear ring gears, and substantial 8-inch gears in the front (independent) diff. So I suspect this won’t be the problem it is for those kids who stick 42-inch Mudders on Toyota pickups with 7.5-inch front diffs, then punch the locker when one wheel is spinning in thin air.

On the other side of the coin, the lower crawl ratio in the Montero is a definite asset, since it allows Scott to tackle rough sections at lower speeds, reducing the possibility of drivetrain stress, enhancing engine braking on descents, and easing transitions into off-camber situations with that higher CG. Of course high range isn’t negatively affected, so road performance remains normal—although I’d bet the combination of weight, windage, lift, and tires on Scott’s vehicle drops fuel economy of the V6 into the low teens more often than he’d like.

The last concern for Scott would be stress on the Montero’s bodywork and chassis. Again, he’s fortunate to have a strong, fully boxed ladder frame with no known weak points. The front double-wishbone and multilink rear suspension structure is sturdy and easy to modify for increased capacity. The roof rack mounting points on the drip rails might be a concern, but frequent inspection should be sufficient to detect any incipient issues.

What do the lessons from Scott Lesak’s thoughtfully outfitted, but overloaded, Montero tell the rest of us?

First, most obviously, is that if possible one should keep the all-up weight of the vehicle below the manufacturer’s GVWR. It’s easy to add a set of heavy-duty springs or air bags and then just start throwing stuff in, but just because the truck sits level doesn’t mean it isn’t dangerously overloaded. Scott showed a great deal of thoughtfulness by calculating the total weight of his Montero; how many of us have done the same, or paid five bucks at a commercial scale to see what our fully loaded overland vehicle weighs? With solid figures in hand, it’s a lot easier to decide if action is necessary to alleviate the situation.

However, rather than assembling a completely modified vehicle and camping kit, and then finding out what it all weighs, a better and less expensive strategy would be to learn from Scott’s example, and pay attention to weight from the beginning, when first modifying the vehicle and buying camping gear.

It’s common for those starting out in the overlanding world to be tempted to get the “look” down first (I certainly was). Those winch-mounted bull bars, roof racks with six driving lights, and multi-function rear bumper/swing-outs look absolutely ace, but each one not only adds weight, it does so in the worst possible place: on the ends of the vehicle, and on top. Decide carefully whether or not you really need each. How I wish more manufacturers made sturdy winch bumpers without the bull bar, which very, very few of us really need. But apparently the market demands the full-on Aussie look . . .

Camping equipment can get out of hand easily too. Personally I think it’s odd to drive a 4,000-pound vehicle somewhere, then sleep in a five-pound mountaineering tent and cook over a microweight backpacking stove, as some friends do—but if sleeping and eating are just chores to be dealt with for you in between hikes or fishing, why carry more weight? I like to tell people to evaluate their priorities and splurge there first. For example, when car camping I like to have a tent with stand-up headroom inside, and real cots to sleep on. But I’m happy with a single-burner stove and one-pot meals. Roseann enjoys cooking, so she prefers a more comprehensive kitchen. We’ve picked and chosen to arrive at a compromise—a modest-sized but full-height tent and lightweight aluminum cots; a well-equipped kitchen mitigated by such things as a Worthington aluminum propane cylinder, which weighs half what an equivalent steel tank does. The result is a comfortable camping setup for two people (a vital distinction from Scott’s family situation). Yet, according to my calculations taking into account the known weight of our FJ60 (with M8000 winch, Slee rear bumper, and 40 gallons of diesel), with everything aboard we are just nudging past its 5,380-pound GVWR—not too bad.

When loading gear for a trip, remember that everything adds up, not just the big bulky items. Do you really need an axe, or would a hatchet or folding saw suffice? One day not long ago I finally tossed out the never-used 25-pound choker chain in our winch kit. What a difference that made. I also discovered we had somehow wound up with two folding shovels in the vehicle—not really necessary. And what on earth was that old three-D-cell Maglite still doing stuffed under the front seat? Two pounds saved . . .

If you do find yourself unavoidably abusing your vehicle’s GVWR, there are several ways to mitigate the potential side effects. First, make sure your most vital item of safety gear—the braking system—is completely up to snuff. Eschew the $49.99 lifetime brake job at the muffler shop and install the best brake pads and shoes you can find. Likewise, suspension bits should be the best available. I’ve found that, especially with shock absorbers, you really do get what you pay for. If your vehicle is equipped with anti-roll bars (a.k.a. sway bars), consider upgrading them to thicker units to reduce body roll in turns (although this will diminish compliance on trails unless you have disconnectable bars). And when on a trip, force yourself to check everything on the vehicle religiously, from the tires on up, every day—particluarly those pieces that take the most abuse from weight.

Research your vehicle to see if there are well-known weak points in its running gear or chassis. The internet has made this child’s play—you can bet if a vehicle has a common problem, word will get out. For example, a search for “Toyota Tacoma frame problems” will acquaint you with the known weakness in the rear of the frames on first-generation Tacomas. Several companies sell weld-in gussets to address the issue on this otherwise superb truck. Mid-80s Chevy trucks are notorious for numerous frame, shock-mount, and steering box weaknesses. Even Ford’s recent über-truck, the Raptor, is showing early signs of a serious chassis flaw, at least for those owners who insist on driving them like the commercials suggest. All these problems have been extensively discussed on the web.

Finally, most obviously: Pay attention to your driving, and adjust it to suit the lower capabilities of the overloaded vehicle in terms of braking performance, emergency maneuvering, side-slope security, and so on.

What would I do differently in Scott’s place? Monday-morning quarterbacking is the easiest job in the world. However, given the situation he described, I’d be very tempted to look into a 4WD-capable utility trailer from one of the growing number of companies offering them. Offsetting the hassle of a trailer would be the elimination of that 150-pound roof rack (and ladder), and the redistribution of its load, along with much more gear from the Montero’s cargo bay—which would likely mean that the 100-pound drawer system could be tossed out, along with, perhaps, the 45-pound cargo barrier. That 280 pounds of water could go in the trailer as well, as could the jerry cans which now have to reside on that 200-pound custom rear bumper and swing out. Toss that too (or go for a much lighter Hi-Lift-capable bumper with just a tire mount). With the fridge in the trailer the 50-pound fridge slide could go. We just lost over 500 pounds in one paragraph—which would, ahem, go some ways toward offsetting the weight of the trailer (although towed weight is much different from carried weight). The entire load would be distributed much more evenly (and lower), relieving the burden on the Montero. I’d be curious to see a controlled experiment regarding highway fuel economy comparing a vehicle with a high roof load to one towing a utility trailer. I strongly suspect the trailer would add more drag, but it might not be a huge difference.

On the vehicle itself, a few things jumped out at me, but again from my own perspective. The Garvin roof rack seems immensely heavy—the full-length aluminum Front Runner rack we use when necessary on our FJ60 is light enough for me to lift with one arm, yet sturdy enough to stand on. Scott’s 12,000-pound-capacity Mile Marker winch is actually well-matched to the total weight of his vehicle (gross weight x 1.5 is the general rule), but depending on frequency of use I’d be tempted to go with a Warn M8000 and synthetic line—total weight less than 80 pounds—and employ snatch blocks to increase pulling power. That would not only save weight but would remove it from the end of the vehicle, where its effects are magnified.

Scott apparently knows what he needs in the way of tires, given where he wants to go (those dual diff locks and 43:1 crawl ratio are clues). For myself, I’ve never seen a need for tires larger than 33-inch on a vehicle that size. That would eliminate the need for the body lift, thus saving rotating weight (the worst kind) and lowering the center of gravity at the same time.

In the end, while Scott is certainly stretching the load-carrying ability of his vehicle, he could have done much worse than to choose the fine second-generation Montero as his platform. Here’s hoping it and Mark’s twin hold up for many thousands of miles of family adventuring.

Fit to be tied: Tie-down torture tests the metal of Expeditionware Transport Loops

I’m never sure which alarms me more: a vehicle loaded with completely unsecured cargo and equipment, or one loaded with cargo and equipment secured poorly. After all, the former implies simple ignorance on the part of the owner, and ignorance can be overcome with education. But the latter implies some rudimentary level of awareness—and then a complete failure to do the simple arithmetic that will tell you what will happen to the 30-pound Hi-Lift jack bungeed to your front brush guard should you be, say, rear-ended at a stoplight. No, I am not making this up, and yes, I checked. Two neatly wound bungee cords comprised the total attachment of that jack to that brush guard. I’ve seen another Hi-Lift bungeed to a very well-constructed internal roll cage (talk about Manichaean reasoning), and uncounted tool boxes, fridges, and Pelican cases all held down by what are, let’s be frank, glorified rubber bands.

I’m never sure which alarms me more: a vehicle loaded with completely unsecured cargo and equipment, or one loaded with cargo and equipment secured poorly. After all, the former implies simple ignorance on the part of the owner, and ignorance can be overcome with education. But the latter implies some rudimentary level of awareness—and then a complete failure to do the simple arithmetic that will tell you what will happen to the 30-pound Hi-Lift jack bungeed to your front brush guard should you be, say, rear-ended at a stoplight. No, I am not making this up, and yes, I checked. Two neatly wound bungee cords comprised the total attachment of that jack to that brush guard. I’ve seen another Hi-Lift bungeed to a very well-constructed internal roll cage (talk about Manichaean reasoning), and uncounted tool boxes, fridges, and Pelican cases all held down by what are, let’s be frank, glorified rubber bands.

I’m never sure which alarms me more: a vehicle loaded with completely unsecured cargo and equipment, or one loaded with cargo and equipment secured poorly. After all, the former implies simple ignorance on the part of the owner, and ignorance can be overcome with education. But the latter implies some rudimentary level of awareness—and then a complete failure to do the simple arithmetic that will tell you what will happen to the 30-pound Hi-Lift jack bungeed to your front brush guard should you be, say, rear-ended at a stoplight. No, I am not making this up, and yes, I checked. Two neatly wound bungee cords comprised the total attachment of that jack to that brush guard. I’ve seen another Hi-Lift bungeed to a very well-constructed internal roll cage (talk about Manichaean reasoning), and uncounted tool boxes, fridges, and Pelican cases all held down by what are, let’s be frank, glorified rubber bands.

I’m never sure which alarms me more: a vehicle loaded with completely unsecured cargo and equipment, or one loaded with cargo and equipment secured poorly. After all, the former implies simple ignorance on the part of the owner, and ignorance can be overcome with education. But the latter implies some rudimentary level of awareness—and then a complete failure to do the simple arithmetic that will tell you what will happen to the 30-pound Hi-Lift jack bungeed to your front brush guard should you be, say, rear-ended at a stoplight. No, I am not making this up, and yes, I checked. Two neatly wound bungee cords comprised the total attachment of that jack to that brush guard. I’ve seen another Hi-Lift bungeed to a very well-constructed internal roll cage (talk about Manichaean reasoning), and uncounted tool boxes, fridges, and Pelican cases all held down by what are, let’s be frank, glorified rubber bands.

Bungees have their uses, but heavy cargo in an overland vehicle should be secured with ratchet straps capable of withstanding the forces generated should you experience an unplanned encounter with Isaac Newton. Anything much heavier than a sleeping bag can cause injury or worse in an accident or rollover. (Come to think of it, I wouldn’t want to be clobbered by my 18-pound Butler sleeping bag . . .)

Decent ratchet straps are available at any hardware store. But very few, if any, vehicles come from the factory with tie-down points strong enough and numerous enough to anchor those straps. It’s almost always up to the owner to add proper loops or eye bolts. The conundrum of where to locate them is rarely solved permanently. A few items such as the fridge might have a more or less permanent location, but the distribution of other gear is subject to change, and to the addition of new gear. Bolt in too many tie-down loops and they can be almost as much a hindrance as a help to properly securing stuff. Adjustable rails such as those from Mac’s Custom Tie-Downs add versatility; the anchor plate systems from the same company, which leave only an unobtrusive rounded base when not needed, are useful as well. But both of these need a fair amount of space to install.

A few years ago, while looking for tie-down loops for the rear of my FJ40, I found the Ring Products Transit Loops at Expedition Exchange. The stainless-steel loops were originally designed to be attached to motorcycles to provide easily accessible points on which to hook tie-down straps when transporting the bike on the trailer or in a truck. Lightweight and unobtrusive, they obviated the need to loop cinch straps awkwardly around handlebars or luggage racks. However, with my FJ40 in mind, I realized they looked just the right size to bolt down on top of the join between the body tub and hardtop, using the numerous existing 10mm bolts.

Indeed, such proved the case, and a half dozen of the rings gave me a solid perimeter tie-down system. I added a few more on the wheel wells, then started looking at our other vehicles and realizing there were a nearly infinite number of places the little rings could be utilized to secure a nearly infinite number of items. They could be installed in very tight spaces, and needed only a single 1/4-inch hole to mount. Visually, a pair didn’t look like overkill when securing something as small as a pack of road flares (with a bungee—a proper use for one), but four of them would lock down an Engel immovably.

And then the company went out of business. Damn.

I moved on to other tie-down systems for other projects—but how I missed those versatile little rings.

The fellows at Expedition Exchange apparently shared my thoughts, because after trying in vain for years to track down the Ring Products company or principals, they decided they’d exercised due diligence—and had a leftover reproduced at a local machinist. Skimming the EE website a few months ago, I noticed the newly introduced Expeditionware Transport Loops. Woohoo! I immediately ordered some to look at, and found them to be apparently exact copies. Excellent.

However, as I examined the new loops I found myself, for the first time, wondering about the ultimate strength of such a compact fitting. I’d always assumed that, since four of the originals were designed to hold down a motorcycle during road transport, they were certainly strong enough to secure a fridge or a Pelican case full of tools. But now I was curious about their limits.

With a loop in hand, I looked around our shop and carport for a way to put it to the test. I had neither a strain gauge nor a scale sufficient to register the several hundred pounds I assumed the loop would take before it failed. Bolt it to one of the steel roof beams in the carport and hang successive weights off it? Perhaps, but how to suspend 400—or 600 or 800—pounds in successive increments? Hook one between two Land Cruisers and try to pull it apart? But that wouldn’t tell us what the failure point was, and sounded like a procedure that would wind up either as an object lesson at the next Overland Expo, or a feature on YouTube.

With a loop in hand, I looked around our shop and carport for a way to put it to the test. I had neither a strain gauge nor a scale sufficient to register the several hundred pounds I assumed the loop would take before it failed. Bolt it to one of the steel roof beams in the carport and hang successive weights off it? Perhaps, but how to suspend 400—or 600 or 800—pounds in successive increments? Hook one between two Land Cruisers and try to pull it apart? But that wouldn’t tell us what the failure point was, and sounded like a procedure that would wind up either as an object lesson at the next Overland Expo, or a feature on YouTube.

But, hmm . . . the Land Cruiser. I looked at the rear bumper/tire carrier on the FJ40, specifically at the stout, one-inch-thick shackle mounts on either corner. Then I looked at the Hi-Lift jack nearby. That might do . . .

Using a grade 8 bolt and some graduated washers, I affixed the ring to the shackle mount via the smaller of its two holes. Then, with a steel quick-link connector through the larger hole, I attached the ring to the slot on the bottom of the Hi-Lift’s tongue, which I’d position just above the shackle mount.

Now I had a mechanism, but I still didn’t have a means of measuring the stress on the ring. Given that my FJ40 weighs a bit over 4,000 pounds, I decided rather arbitrarily that if I could lift one rear wheel off the ground—or even come reasonably close to doing so—the Expeditionware Transport Loop would have proved its mettle as far as I was concerned. I donned a heavy Carhart jacket, gloves, and safety glasses in case the ring exploded and flung bits of stainless steel hither and yon.

I began working the Hi-Lift’s handle and the loop took up strain. The assembly started to emit ominous metallic creakings, and for the first time I begin to wonder if this was a good idea. How could I expect a tiny ring a few millimeters thick to lift a corner of a 4WD vehicle?

The bumper rose, and the right rear leaf spring started to flex. Now, if I peaked around the Hi-Lift’s main beam, which I was keeping between me and the poor little ring, I could see the latter flattening. Was there some stretching going on as well? The sidewall bulge came out of the right rear tire as the bumper continued to rise with each stroke of the jack handle, but it remained planted on the ground. Now I could clearly see the large hole in the Transit Loop elongating. More creaking, and a ping or two from somewhere in there.

The bumper rose, and the right rear leaf spring started to flex. Now, if I peaked around the Hi-Lift’s main beam, which I was keeping between me and the poor little ring, I could see the latter flattening. Was there some stretching going on as well? The sidewall bulge came out of the right rear tire as the bumper continued to rise with each stroke of the jack handle, but it remained planted on the ground. Now I could clearly see the large hole in the Transit Loop elongating. More creaking, and a ping or two from somewhere in there.

But then—the tire was a few millimeters off the ground. I could spin it with a boot. A single Transit Loop had successfully lifted the corner of an FJ40 off the ground—and one equipped with a massive Stout Equipment bumper/tire rack at that.

I have no way of knowing exactly how much strain the loop was withstanding at the end, but I’m certainly convinced that, employed in suitable numbers, the Expeditionware Transit Loops are more than up to the job of safely locking down the heaviest fridges, tool boxes, and equipment cases.

At nine bucks each you can afford to buy a bunch. I guarantee you’ll find uses for as many as you have.

Unless you’re still convinced a bungee or two will suffice. Expeditionware Transport Loops

The Myth of Compression Braking

Recently a remark by an acquaintance triggered me to dredge up a bit of knowledge I came by ages ago, during a short stint driving a diesel tractor/trailer rig for J.C. Penney between Phoenix and Tucson. The fellow, a UK resident, had recently sold his mid-90s Land Rover Discovery V8 with a five-speed manual transmission, and purchased a similar Discovery equipped with a 200 Tdi turbodiesel engine, also with a five-speed. Besides instantly doubling his fuel economy and then some, he’d noticed something else and mentioned it in an email. “I might be daft,” he wrote, “but I swear the petrol engine had better compression braking. But I know that’s impossible. It only had 9:1 compression, and the Tdi is 19:1. Something else must be at work.”

Recently a remark by an acquaintance triggered me to dredge up a bit of knowledge I came by ages ago, during a short stint driving a diesel tractor/trailer rig for J.C. Penney between Phoenix and Tucson. The fellow, a UK resident, had recently sold his mid-90s Land Rover Discovery V8 with a five-speed manual transmission, and purchased a similar Discovery equipped with a 200 Tdi turbodiesel engine, also with a five-speed. Besides instantly doubling his fuel economy and then some, he’d noticed something else and mentioned it in an email. “I might be daft,” he wrote, “but I swear the petrol engine had better compression braking. But I know that’s impossible. It only had 9:1 compression, and the Tdi is 19:1. Something else must be at work.”

I wrote him back a short reply: “That’s because diesel engines have no compression braking.” Which caused him to respond, “Now I think you’re daft.”

Recently a remark by an acquaintance triggered me to dredge up a bit of knowledge I came by ages ago, during a short stint driving a diesel tractor/trailer rig for J.C. Penney between Phoenix and Tucson. The fellow, a UK resident, had recently sold his mid-90s Land Rover Discovery V8 with a five-speed manual transmission, and purchased a similar Discovery equipped with a 200 Tdi turbodiesel engine, also with a five-speed. Besides instantly doubling his fuel economy and then some, he’d noticed something else and mentioned it in an email. “I might be daft,” he wrote, “but I swear the petrol engine had better compression braking. But I know that’s impossible. It only had 9:1 compression, and the Tdi is 19:1. Something else must be at work.”

Recently a remark by an acquaintance triggered me to dredge up a bit of knowledge I came by ages ago, during a short stint driving a diesel tractor/trailer rig for J.C. Penney between Phoenix and Tucson. The fellow, a UK resident, had recently sold his mid-90s Land Rover Discovery V8 with a five-speed manual transmission, and purchased a similar Discovery equipped with a 200 Tdi turbodiesel engine, also with a five-speed. Besides instantly doubling his fuel economy and then some, he’d noticed something else and mentioned it in an email. “I might be daft,” he wrote, “but I swear the petrol engine had better compression braking. But I know that’s impossible. It only had 9:1 compression, and the Tdi is 19:1. Something else must be at work.”

I wrote him back a short reply: “That’s because diesel engines have no compression braking.” Which caused him to respond, “Now I think you’re daft.”

My next email was much longer, and read something like this:

First, the term “compression” braking is a misnomer. While there are several forces at work (including simple internal friction) when a driver lifts off the throttle in a vehicle and the engine slows it, the force often referred to as compression braking is more accurately called vacuum braking. It occurs in a gasoline engine because the throttle, i.e. the gas pedal, works by regulating the amount of air entering the engine—the fuel-to-air ratio is kept relatively constant. The air flow is controlled by a rotating plate or series of plates in the fuel injection’s intake system (or, in older vehicles, in the carburetor). When you lift off the gas pedal, that plate closes off the intake nearly completely. The engine, which is still turning at speed via its connection to the turning wheels, then has to suck air past the closed plate, and that retards the engine, and that is what allows our manual-transmission, gasoline-engined vehicles to creep down quite steep inclines in first gear low range, without the need for brakes.

A diesel engine is different. In a diesel, the throttle controls the amount of fuel being injected into the engine, rather than the air flow. The air intake system in a diesel is always fully open. Thus, when you lift off the pedal in a diesel-engined vehicle, the fuel supply is reduced, but there is no vacuum effect to slow the engine. Thus, no “compression” braking.

You might ask, but what about the air still being compressed in each cylinder as the piston rises on that 19:1 compression stroke? Doesn’t that retard the engine? The answer is, yes, it does; however, once the piston passes top dead center, that compressed air is still pushing against the piston, only now it’s trying to speed up the engine, even without enough fuel injected to produce real power via combustion. So the two forces essentially cancel each other (the same effect applies to gasoline engines).

Opening photo: A 3.8-liter gasoline engine. This photo: A 3.0-liter Turbodiesel. Which one has more engine braking?

Opening photo: A 3.8-liter gasoline engine. This photo: A 3.0-liter Turbodiesel. Which one has more engine braking?

This lack of what we really should just refer to as engine braking is why many big diesel trucks, such as that J.C. Penney tractor/trailer rig, employ what is known generically as a Jake brake, after Jacobs, the company that originally manufactured the device. A Jake brake opens the exhaust valve on each cylinder at the top of the compression stroke, so the compressed air is released out the exhaust (with a machine-gun-like hammering that prompts communities to post those signs prohibiting their use within urban areas). That leaves just the compression stroke working to retard the engine—so a diesel truck with a Jake brake really does have compression braking.

The exhaust brake is another, quieter (although generally less effective) method of engine braking on a diesel truck. This device partially closes off the exhaust, so the air pushed out through the exhaust valve on the exhaust stroke is restricted, slowing the engine and the vehicle. Some trucks now employ both Jake and exhaust brakes to maximize efficiency while reducing noise.

So that’s why an engine with more compression can have less “compression” braking.

I checked: Unfortunately, Jacobs doesn’t make a model for the 200 Tdi . . .

Do I really need a winch?

Recently my friend Sergio Mendez Santiago emailed me from Puerto Vallarta, Mexico, where he and his wife, Ruth, are putting the finishing touches on their new Mitsubishi Triton, a fine turbodiesel-powered 4WD pickup (sadly unavailable in the U.S.). Like so many of us setting up a new vehicle, Sergio has been vacillating on the decision of whether or not to install a winch. We both thought it would be a good subject to explore. Since I have a Warn 8274 on my FJ40, and I installed a Warn M8000 on Roseann’s FJ60, I certainly appreciate their value (and I think my objectivity is on solid ground)—however, I certainly don’t think one absolutely needs a winch to be able to undertake even ambitious journeys.

Recently my friend Sergio Mendez Santiago emailed me from Puerto Vallarta, Mexico, where he and his wife, Ruth, are putting the finishing touches on their new Mitsubishi Triton, a fine turbodiesel-powered 4WD pickup (sadly unavailable in the U.S.). Like so many of us setting up a new vehicle, Sergio has been vacillating on the decision of whether or not to install a winch. We both thought it would be a good subject to explore. Since I have a Warn 8274 on my FJ40, and I installed a Warn M8000 on Roseann’s FJ60, I certainly appreciate their value (and I think my objectivity is on solid ground)—however, I certainly don’t think one absolutely needs a winch to be able to undertake even ambitious journeys.

Recently my friend Sergio Mendez Santiago emailed me from Puerto Vallarta, Mexico, where he and his wife, Ruth, are putting the finishing touches on their new Mitsubishi Triton, a fine turbodiesel-powered 4WD pickup (sadly unavailable in the U.S.). Like so many of us setting up a new vehicle, Sergio has been vacillating on the decision of whether or not to install a winch. We both thought it would be a good subject to explore. Since I have a Warn 8274 on my FJ40, and I installed a Warn M8000 on Roseann’s FJ60, I certainly appreciate their value (and I think my objectivity is on solid ground)—however, I certainly don’t think one absolutely needs a winch to be able to undertake even ambitious journeys.

Recently my friend Sergio Mendez Santiago emailed me from Puerto Vallarta, Mexico, where he and his wife, Ruth, are putting the finishing touches on their new Mitsubishi Triton, a fine turbodiesel-powered 4WD pickup (sadly unavailable in the U.S.). Like so many of us setting up a new vehicle, Sergio has been vacillating on the decision of whether or not to install a winch. We both thought it would be a good subject to explore. Since I have a Warn 8274 on my FJ40, and I installed a Warn M8000 on Roseann’s FJ60, I certainly appreciate their value (and I think my objectivity is on solid ground)—however, I certainly don’t think one absolutely needs a winch to be able to undertake even ambitious journeys.

No matter what vehicle you drive, from a two-wheel-drive pickup with street tires to a Jeep Rubicon on BFG Mud-Terrains with diff locks front and rear, a 4:1 transfer case, disconnecting sway bar, etc. etc, you’re going to find yourself in situations for which a judgement call is needed. Obviously the two-wheel-drive pickup will have a much, much lower threshold at which discretion should kick in and you turn around, but the Rubicon will have its own threshold, beyond which you stand a good chance of getting stuck.

In such cases, a winch can give you the leeway to push the threshold, a little or a lot depending on several factors:

- Are you with other vehicles that can serve as anchor points for the winch line, or which are equipped with winches themselves?

- If you are traveling solo, are there natural anchor points, such as substantial trees, within reach of your winch line? If not, would it be possible to rig an anchor, such as by burying a spare wheel in sand?