Overland Tech and Travel

Advice from the world's

most experienced overlanders

tests, reviews, opinion, and more

A different Dormobile

Most people reading this are familiar with the iconic Land Rover Dormobile and its clamshell pop-up roof, which converts a long-wheelbase Series II into a stylish camper with full standing headroom. But I didn’t realize that Dormobile modified other vehicles as well, such as this 1961 Bedford CA van. Very practical if you didn’t need the four-wheel-drive of a Land Rover. Read more about it on Silodrome, here.

The truth about aftermarket "high-performance" brakes.

Few people reading this would argue that the single most important component of your vehicle is the braking system. Everything else—engine power, handling, comfort, fuel economy, off-pavement capability, number of USB outlets—is secondary to the critical need to be able to stop that vehicle safely and quickly, time after time.

Yet despite that single-purpose, critical function, there are a lot of myths circulating about brakes, how they work, and how they can be improved—and a lot of those myths originate from, or are promulgated by, companies trying to sell you something.

In terms of physics, brakes do exactly one thing: They convert the kinetic energy of the moving vehicle into thermal energy, i.e. heat. All brakes function this way, whether disc, drum, or Fred Flintstone’s feet. In fact, even the parachute on a top-fuel dragster converts the kinetic energy of the vehicle into heat, through friction with the atmosphere; it is simply dissipated more diffusely in the dragster’s slipstream.

The energy those brakes must convert does not increase linearly with speed; instead it increases with the square of speed (kinetic energy equals mass times velocity squared). Thus a vehicle moving at 50 mph requires four times as much energy conversion to stop as one moving at 25 mph, and one moving at 100 mph requires sixteen times as much. Given the same speed and the same vehicle weight, the heat produced by stopping is also the same, whether it is done via cast-iron drum brakes on a Series 2 Land Rover or the carbon-ceramic discs on a Porsche GT3.

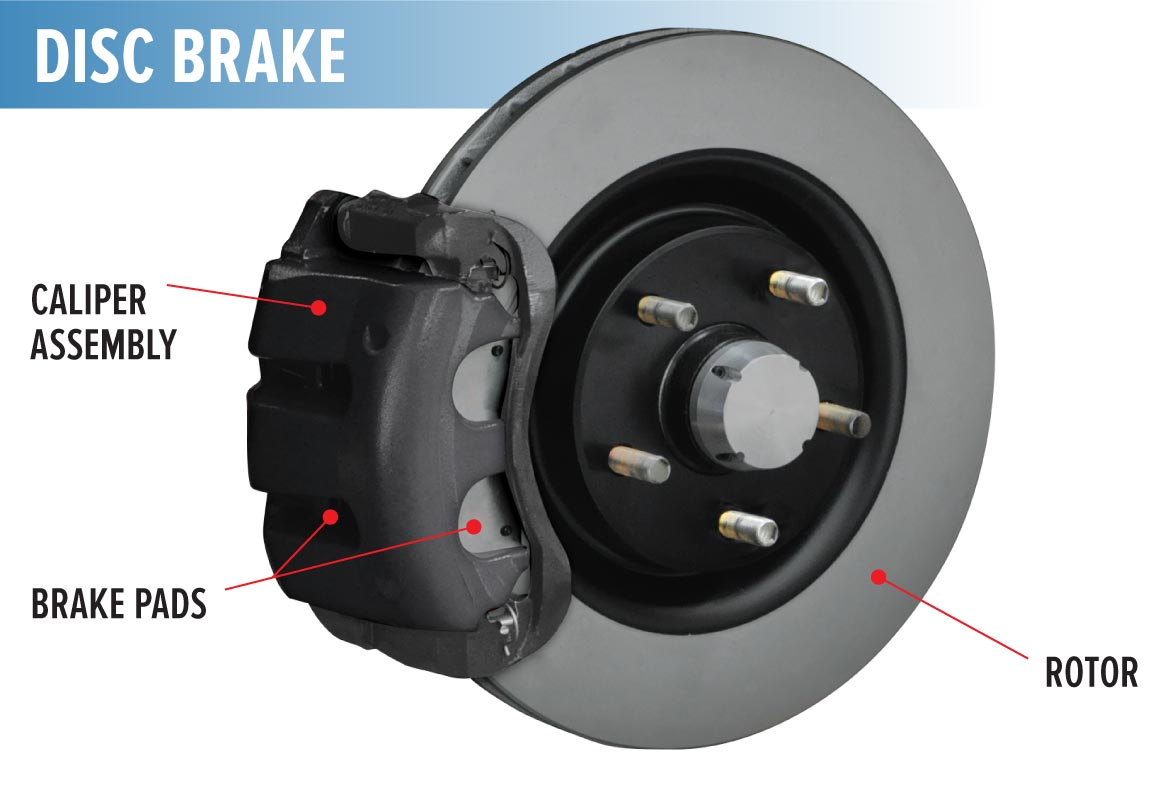

The basic operation of a brake goes like this: When the driver presses the brake pedal, the pedal pushes a plunger into a hydraulic cylinder filled with brake fluid—a viscous substance resistant to heat. The cylinder, called the master cylinder, is connected to a brake caliper in each wheel via tubes. The caliper wraps around the perimeter of the brake disc, and incorporates a piston on each side (sometimes several), which bear against brake pads made of friction-resistant material. The master cylinder forces the brake fluid, which is essentially incompressible (more about that later) through the tube and against the pistons in the caliper, which in turn push the brake pads against the disc, squeezing the disc (also called the rotor) with tremendous force, creating friction and slowing the vehicle.

The drum brake, which has virtually disappeared except on the rear axles of the cheapest economy cars and Toyota Tacomas (see here), is different. Instead of a flat disc there is a cast-iron drum shaped like a flat pan with vertical sides, turned vertically so it rotates with the wheel. The master cylinder pushes against a slave cylinder (a quaint term, no?) which in turn pushes a friction-resistant brake “shoe” against the drum. Drum brakes have (mostly) gone the way of flathead V8s and carburetors because they retain more heat (more on that soon) and don’t work well when wet.

There have been many advances to the basic hydraulic braking system. Originally (and still in a few applications) each caliper employed only one piston and the caliper could slide slightly back and forth. The piston pushed one brake pad against the disk while simultaneously pulling the opposite pad against the other side. This was much less efficient than the later multi-piston calipers. Modern brake calipers on high-performance sports cars can employ six or even eight opposed pistons.

Virtually all brakes today are power-assisted via a vacuum-operated device incorporated into the master cylinder. This reduces braking effort, sometimes hugely in the case of a heavy truck. Also, all brake systems are now (by law) dual-circuit: The master cylinder is essentially two master cylinders combined in line, each of which operates on both front brakes and one rear brake. This redundancy insures that if one circuit fails, the vehicle will still retain reasonable stopping power.

A big advance in the efficiency of brakes arrived with anti-lock braking systems (ABS), which use a simple sensor at each wheel to monitor revolutions of the wheel. If a sensor detects a wheel locking up (i.e. turning slower than the others or stopping altogether), the ABS computer pulses power to that brake so that it unlocks. This system reduces braking distances and increases the driver’s control over the vehicle. (To see why a turning tire stops shorter than a skidding tire, look here.)

As vehicles have become heavier—and wheel diameters larger—manufacturers have been installing larger and larger-diameter discs in their brake systems. Most disc brakes are now ventilated—the disc comprises two discs joined by a vaned center section to dissipate heat more effectively. Thanks to such advances—as well as better tire compounds—average braking distances have been steadily shrinking.

Mostly.

Obviously it’s easier to stop a light vehicle than a heavy one. By extension we can state categorically that it is easier to stop, say, a stock FJ60 Land Cruiser than one that has been modified with an ARB winch bumper and a Warn 9,000-pound winch, a rear spare/jerry can rack, a roof rack, a 60-liter fridge, a drawer system, an auxiliary fuel tank, and . . . you get the picture. With surprising suddenness your 5,000-pound Land Cruiser x velocity squared can become a 7,000-pound Land Cruiser x velocity squared.

I discovered the results on our own FJ60 on a biological survey in Mexico’s Sierra Madre some years back. This 60 had a turbodiesel engine conversion plus most everything on the list above. And on a steep, winding descent of about 3,000 feet, the brake pedal began to feel mushier and mushier, even as I downshifted to use engine braking. By the time we reached the plains the brakes had seriously deteriorated, and only regained effectiveness after ten minutes of cooling down.

I had experienced classic brake fade.

Brake fade can occur essentially two ways. First, a brake pad can overheat from extended application—such as a long descent—and form a slick glaze on its surface. When this happens the brake pedal will still feel firm, but increased pressure will have little or no effect. Second, the brake fluid itself can heat to its boiling point. When this happens, the fluid turns to a gas—and gas, unlike the fluid, is compressible. So your desperate standing on the pedal just compresses the gas in the calipers and does little to squeeze the brake pads. This is what we experienced. The condition can be aggravated if you don’t regularly flush your brake system. Brake fluid is hygroscopic, meaning it absorbs water, and since water has a much lower boiling point than pure brake fluid, old, contaminated fluid can cause premature boiling and fade.

Of course even stock vehicles with no weighty accessories bolted to them can be subject to brake fade, and even if no calamities ensue when it occurs it is a deeply unsettling experience. The logical first response is, “I need better brakes!” Indubitably true, but the path to obtaining them is fraught with hype and numerous ways to spend lots of money for very little if any gain.

Let’s start with that brake fluid. Brake fluid is graded on a DOT scale, based on its minimum boiling point, both dry (uncontaminated with water), and wet (contaminated). Most braking systems come from the factory filled with DOT 3 fluid, which has a minimum boiling point of 401ºF dry and 284º wet (see now how much water can degrade your brakes?). Dot 4 fluid is rated at 446º and 311º minimum, respectively, and DOT 5.1 fluid carries a 518º and 374º rating. So simply spending 20 bucks or so upgrading your brake fluid can give you a full 100-degree margin over DOT 3 before gassing occurs. Note that these standards are minimums; many premium brake fluids will perform well above that and will say so on the label. And what happened to DOT 5 fluid? That’s a silicone-based fluid as opposed to the glycol base of DOT 3, 4, and 5.1. You can mix glycol-based fluids all you like, but cannot mix glycol and silicone fluids.

It will do little good to install better, high-temp brake fluid if your brake pads are sub-standard. Most vehicles come from the factory with organic-compound pads, or NAO (non-asbestos organic). These are sufficient for most use—they are quiet, don’t create much brake dust, and are easy on the discs—but if overheated can be subject to the glazing we discussed earlier. Semi-metallic pads, which are a mixture of iron, copper, steel, and graphite in an organic matrix, are significantly more resistant to glazing, at the expense of (sometimes) more noise, more dust, and faster disc wear—and of course slightly higher cost. A third type of brake pad, ceramic, attempts to solve the noise and dust issues of semi-metallic pads, and is resistant to fade, but less aggressive and generally not recommended for heavy-duty use, especially in cold climates—although the technology is still advancing..

So if your braking system is in good order, you’ve upgraded your brake fluid and switched to semi-metallic pads, and you’re still experiencing brake fade, what then? (I’ll refrain from suggesting, “Leave some of that crap at home.”) It might be time for a more drastic upgrade.

And that’s where marketing hype gets really tricky.

Many commercial kits (as well as a whole bunch of do-it-yourself threads on forums) “upgrade” the front brakes—where most braking occurs—simply by means of replacement calipers with more and/or larger pistons and larger pads than the originals. More pistons equals more squeeze and better braking, right?

Not so fast.

Remember all that kinetic energy we’re turning into thermal energy every time we stop? That energy (heat) has to be dissipated to enable repeated stops—or a safe descent down a mountain grade—without overheating the pads or brake fluid. And the way that heat is dissipated is through the brake disc. So if you install more powerful calipers on your existing discs, here’s what’s likely to happen: You’ll take the vehicle out for a trial run around town, and be impressed at the increase in stopping power. Those new four- or six-piston calipers grab that disc right now. Awesome. So you’ll then head confidently to that long downhill that resulted in a scary spongy brake pedal last month, and . . . oh. Whoa. Halfway down, the pedal feels like it’s got an entire bag of Sta-Puft marshmallows between it and the calipers. That’s because you’ve installed the means to inject more heat into the braking system without installing the means to get rid of it. As long as you’re just trundling around town you’ll get some benefit from the more powerful calipers, but under prolonged application all they’re likely to do is make your fade problem worse.

Okay . . . plan B then. Let’s install a set of those fancy (and awesome-looking) cross-drilled brake discs. You know, like Porsches and Ferraris have? Cross-drilled discs stay cooler, right, with all those holes?

Sorry . . . wrong again.

Cross-drilling of brake discs began in the early days of disc brakes, when existing pad materials and adhesives tended to outgas strongly when heated. Cross-drilling relieved the fractional layer of (compressible, remember) gas the pad would exude between it and the disc. But modern brake pads exhibit virtually none of this outgassing. More importantly, a cast-iron brake disc relies on its mass to absorb and dissipate heat. When you drill a bunch of holes in it, you are reducing that mass. (One company actually boasts that its drilled discs are 16 percent lighter than non-drilled discs.) Some arguments—especially from those who sell them—still maintain that the ventilation and added surface area of cross-drilled discs provide enough cooling to offset the loss of mass. But the further I investigated, the more testimonials I read from objective experts in the field who called nonsense. At best, many referred to any cooling effect as a wash, and several pointed out how often cross-drilled discs wind up plugged with brake dust—a giveaway that not much air flow is occurring through those holes (unlike the well-documented radial flow through the center vanes of a ventilated disc). Add to that the fact that, even when properly cast in and chamfered rather than simply drilled, cross-drilling can introduce stress risers into the disc that promote cracking, and you have a powerful argument against it, no matter how stylish it looks. (And if you look at the ads from companies who sell them you’ll be amused at how many mention the style factor as an actual reason to spend your money.)

The sole theoretical advantage to drilled discs mentioned by those same experts was a slightly enhanced initial “bite” in wet conditions, when the holes might provide an exit for surficial water on the disc. But brake pads quickly squeegee water off that surface anyway, so even this attribute is of questionable value in the face of the expense and loss in mass of a drilled disc.

Thus we can say pretty confidently that replacing your plain brake discs with cross-drilled discs of the same size will probably result in no reduction in fade, and could conceivably exacerbate it.

(Incidentally, the above does not apply to disc brakes on motorcycles, since a motorcycle disc is a solid rotor rather than a vented, double-sided unit. On a solid rotor, cross-drilling does at least theoretically create some turbulent cooling flow.)

What about the more recently popular slotted discs? Slots actually perform a different function than drilling. The edges of the slots perform a microscopic scraping function on the pad, keeping the pad surface fresh and possibly forestalling glazing. While they won’t in themselves enhance cooling or prevent heat-related fade, they might help forestall the fade resulting from overheated pads of inferior composition. Be advised, however, that slotted discs, as you might expect, will wear out pads more quickly than solid discs, and are likely to exacerbate any brake-dust issues.

Inevitably, aftermarket manufacturers are now offering discs that are both cross-drilled and slotted. At least the slots will provide some function, and where the slots are there is less room for the pointless holes . . .

All this leads to a logical conclusion. Once you’ve optimized your brake fluid and brake pads—and assuming the rest of your braking system is operating as it should—the only sure way to add braking power and reduce the chance of fade is to install, surprise, larger brakes—specifically discs of larger diameter and/or width, with calipers to match. Sometimes this is possible within the constraints of your existing wheels and front end design, sometimes it is not.

Automobile manufacturers are perfectly aware of this. To give you a random example—outside the realm of overland vehicles but one with which I’m familiar—when Porsche upgraded the 1983 911SC to the 1984 Carrera, including a 15-percent bump in power, they improved the braking by increasing the width of the front brake discs from 20 to 24 millimeters, while keeping the diameter the same at 289mm. For the significantly more powerful Turbo of the same era, they increased both the diameter and the width of the discs, to 300 and 32mm respectively. Those were the largest brakes that could fit within the factory 16-inch-diameter wheels. When Porsche added even more power, they switched to larger-diameter wheels as well to accommodate larger discs.

There is one minor exception to the only-bigger-is-better rule. If you look at different aftermarket discs, you’ll notice significant variations in the spacing of the center cooling vanes. Inexpensive discs will be made with more widely spaced slots, which means there is both less mass in the disc to radiate thermal energy, and less radial air flow as well. The one way an aftermarket disc of the same dimensions as the stock disc might outperform it is if the aftermarket disc has a higher density of vanes, and thus weighs more than the stock disc. StopTech, for example, makes a replacement disc for the Tacoma that is stock diameter, but weighs over a pound more, thanks to more closely spaced vanes. That translates to more thermal capacity.

A comparison of vane spacing on a vented brake disc.

Looking at our own class of vehicles, it is all too easy to find “high-performance” brake kits comprising nothing but inexpensive stock-sized replacement discs that have been cross-drilled and/or slotted. Some of the claims for these border on outrageous.

Note that line, “Improves stopping power up to 30 percent over stock brake rotors.” Seriously? Thirty percent meaning 30-percent shorter stopping distances? Or thirty percent less fade? I’d love to see an independent test of that claim. Also, there is simply no chance that their “custom slots” do any cooling, and they will more than likely increase dust due to the scraping function. Finally, check the “reducing heat” claim at the top, which we know from physics is impossible. The only component in this kit likely to modestly improve braking performance is the semi-metallic pads, if they are replacing stock pads—and those certainly won’t “reduce noise.” That’s a stunning amount of misinformation in a single ad.

Finding kits to actually upgrade brakes is much, much harder, in part because it so often requires installing larger-diameter wheels as well. TRD offers a front disc upgrade kit for Tacomas that increases the disc size from 319mm to 332 mm but still fits within the stock wheels. That’s a worthwhile enhancement.

Redline Land Cruisers offers a Big Brake kit for the front of FJ40s, 55s, and 60s that increases the disc diameter from 12 inches to a full 13.3 inches and includes calipers from a later 100-series Land Cruiser—a significant upgrade. But the kit requires a switch to 17-inch wheels for clearance (the company also wisely recommends rear discs, a larger master cylinder, and a proportioning valve to correctly balance front-to-rear braking force). They also mention a big brake kit for 16-inch wheels, but I’ve not received any more information on that one.

I’ve seen a few other legitimate kits for various vehicles, but there is far more in the way of chaff to wade through to find it. The good news is, I suspect for the majority of us a simple upgrade to better pads and fluid will solve anything but chronic brake fade. If that won’t do it, at least now I hope you’ll be better able to distinguish hype from fact.

And if you really want to drill holes in something, maybe you could take up carpentry . . .

JL Wrangler frame issues

Photo: Brett Stevens

The folks over at Jalopnik have a good and extremely important article about the issues some owners are having with welds on JL Wranglers. The critical issue is the weld that holds the track bar to the frame, and the article includes photos and a video of the problem.

The track bar is what locates the front axle side to side, so if it goes so does directional control and steering—not a good thing.

If you own a JL Wrangler you will probably be receiving information about this, but in the meantime you might want to take action yourself. Reportedly FCA has issued a stop-sale order until the matter is addressed.

The new Defender appears, sort of . . .

Currently making the rounds of forums, at last, is a photo of a heavily disguised test prototype of the much-awaited, much-delayed, resurrected and re-invented Land Rover Defender.

The speculation about this vehicle has been on a level like nothing I’ve seen in the four-wheel-drive universe, even beyond the theories that swirled around Jeep’s re-designed Wrangler.

The Wrangler rumor mill terrified aficionados with hints that the new model would lose its solid front axle for independent suspension—perhaps even on the rear axle as well. Then we heard its separate, fully boxed chassis would be abandoned for unibody construction, rendering it in the faithful’s eyes no more than a glorified jacked-up sedan.

In the event, the new JL Wrangler stayed built the way God intended Jeeps to be built: solid front and rear axles, body-on-fully-boxed-frame construction. Parent company FCA managed to incorporate modern safety and convenience features into a decades-old blueprint, and the new Wrangler remains a superb choice for extended travel in rough country.

Tragically, at least for thousands of traditionalist Land Rover faithful, the exact same rumors (or perhaps I should say rumours) proved well-founded as Jaguar/Land Rover gradually released details of the new Defender. The 2020 replacement for the 70-year-old expedition icon will ride on all-independent suspension and will be built on aluminum-intensive unibody architecture shared with other Jaguar/Land Rover products.

Thus one thing is clear: The old Defender is dead and buried (recent outrageous £150,000 factory specials notwithstanding). No more will Land Rover ship CKD (Complete Knock Down) Defenders in crates to be assembled in developing-world countries and pressed into rough service in the remotest backwaters of the Realm. No more will adventurous owners boast of accomplishing major drivetrain rebuilds with hand tools outside an Angolan village. The new Defender will be a completely different vehicle than the old one. The question is, will it be a better vehicle?

J/LR swears the new Defender will be more capable off-road than its predecessor—not at all an outrageous claim given the huge advancements in traction control systems since the relatively primitive system installed in the last generation. And, honestly, it won’t be difficult to exceed the capabilities of the pre-traction-control Defenders, which relied solely on gearing and compliant suspension to negotiate challenging terrain, thanks to Land Rover’s obstinate decades-long refusal to fit cross-axle differential locks. Even the independent suspension will only be a handicap in certain situations, such as when both front wheels compress upon hitting an obstacle, reducing clearance to the fixed front differential. It will certainly enhance ride and handling. And while traditionalists might not like it, unibody construction actually results in a vehicle with far higher torsional rigidity than a vehicle riding on a separate frame, even a fully boxed one. You simply lose the ability to unbolt the body from the chassis with your sockets and wrenches. And repairing collision or trail damage on a unibody vehicle is considerably more involved.

So the capability will be there. Whether J/LR offers the new Defender in suitably basic form to satisfy those who eschew leather and carpet and 10-inch entertainment screens in their overland vehicles—as well as to create an affordable version—remains to be seen.

One area where I suspect the company will get it right is styling—not that there’s much to tell from the disguised test vehicle. After the PR disaster that was the DC100, I’m willing to bet J/LR went to great lengths to evoke the original’s styling without being overtly retro. I predict it will look properly sturdy and adventurous.

Thus we’ll have a capable vehicle that looks the part. The only remaining big question involves market placement. Will Jaguar/Land Rover aim for existing Defender owners, or will they exploit that iconic model name and shove it toward the upscale end of buyers, those who want the look and the rugged association, but who wouldn’t dream of actually shipping their rugged-looking vehicle around the Darien Gap or across the Strait of Gibraltar and exploring another continent?

If you look at sales history I think the answer is clear. The last Defender—the solid-axle, separate frame, bolted-together genuine expedition machine, went extinct for one reason: It stopped selling. Why would Land Rover aim at the exact same customers with the new one?

In some ways the decision will be out of their hands. A technologically advanced vehicle, built largely out of aluminum, with all-independent suspension, sophisticated traction-control and safety systems, and advanced powerplants, is going to be expensive to produce and will cost a lot to buy. I’ll wager the base price of the new Defender 110 (or whatever it will be called) will be substantially above that of the already dear Wrangler Rubicon Unlimited. The temptation to just go with that and load it up with leather and carpet and entertainment screens will be powerful.

I’ll wager further that ads for the new Defender will be stoked with historical family references, and heavy on images in rainforests and sand dunes. Just which magazines those ads appear in will betray the direction the new Defender will take—towards the real jungle or the concrete one.

Cosmetics versus function . . . and safety

This morning I was scanning the excellent Silodrome site, and found this BJ40 restored by Legacy Overland, one of the ever-growing crop of companies exploiting the skyrocketing values of classic 4x4s such as the Land Cruiser and Series Land Rovers.

Legacy is headquartered in Greenwich, Connecticut. They don't specify where their restorations are done, but from various photos it appears to me to be in some Latin American country, which would make sense given that competitors such as The FJ Company do theirs there, taking advantage of cheap and plentiful labor. However, I have no hard evidence of this, and in any case it's not the location of the workshop that matters, but the quality.

To that: This BJ40 is done up in fine style, with a matt black finish, nicely stitched leather upholstery (emblazoned with the company's crest), lots of shiny new bits, and a beautiful engine compartment showing off the four-cylinder diesel powerplant. It also boasts a few actual trail modifications, such as the Hi-Lift jack, BFG Mud-Terrains, and what appears to be Old Man Emu suspension.

However. Closer inspection reveals a couple of disturbing details.

The front bumper is equipped with shackle mounts and D-rings for recovery. Generally speaking, D-rings are considered inferior to bow shackles for recovery, as the former are only suitable for straight-line pulls. More importantly here, blowing up one photo revealed the D-ring to be stamped with a working load limit (WLL) of one ton, or 2,000 pounds. This is drastically underspecced for a vehicle weighing close to twice that.

Undersized recovery points are alarming, as some poor rookie buyer might quite logically assume they are adequate for their intended (or implied) task. But take a close look at the suspension, and you'll note that all four anti-inversion shackles are installed backwards and upside down. That's more than alarming, as it calls into question every aspect of the assembly of this truck. If something as simple—and visible—as shackles are installed backwards, what horrors might be hidden in the engine or transmission? Roseann and I have been on the receiving end of such horrors, and fixing them when the company at fault has washed its hands of the situation and tacitly invited you to sue them can get very expensive.

Of course the drivetrain of this Land Cruiser might very well be impeccably assembled, and the shackles and recovery points isolated issues. Then again, looking at another of the underside photos I'm wondering what the visible yellow nylon strap is holding up . . .

It's easy to put a cosmetic gloss on a classic vehicle and sell it for a lot of money (this one went for $87,360). But engineering a reliable and safe restoration takes much more skill. If you are contemplating a professionally refurbished classic 4x4 vehicle, do your homework on the company, and perform a very, very close inspection.

Update: On the advice of a commenter, I sent the company an email notifying them of the problems with this vehicle, and suggesting strongly that they contact the new owner and have them rectified.

I heard nothing back.

Side slopes . . .

I've always loved this image of a Series I Land Rover tilted at 45 degrees, with an advisory for drivers that the "safe operating angle" is 30 degrees. When was the last time you saw a consumer vehicle advertise its side slope capability, complete with a photo to prove it?

Negotiating a significant side slope is without doubt the most nerve-wracking maneuver you can do with a four-wheel-drive vehicle—at least it is for me. I remember not too long after I got my FJ40 sticking one of those liquid-filled angle gauges on the dash (Roseann annoyingly referred to it as the "tilt-o-meter"). I took the 40 out on a local trail and put it on what felt like a pretty steep side slope in a rutted section of the track, then looked at the gauge . . . which read 15 degrees. It was humiliating. I drove farther up the slope until I got to 20 degrees, which seemed seriously tipped. At 25 degrees I surrendered, even though I knew intellectually that was well below the danger point for an FJ40. I turned the engine off, left it in gear with the parking brake on, and got out to see what it looked like from someone else's viewpoint.

Oh. Jeez. Seriously? Drawing an imaginary line from the outside tire straight up it was clear there was all kinds of weight left on the safe side of the line. Back inside it stilled looked scary, but significantly less so.

Side slopes always look steeper from inside the vehicle. Photo courtesy Matt Scott

I've since had the FJ40 tipped somewhat beyond 25 degrees (the "tilt-o-meter," however, is long gone, replaced by an iPhone app when needed . . .), and had a Jeep Wrangler Rubicon to significantly beyond that. But those kinds of angles remain wince-inducing for me.

And that's a good thing, because side slopes in the real world aren't like tipping a vehicle up on a table in a garage for a photo. When you are moving across an incline of dirt or mixed substrate or rocks, that safe-but-thrilling 20 or 25-degree angle can transition to a very-possibly-unsafe 30 or 35 degrees or worse in an instant if a downhill tire hits a divot or an uphill tire hits a rock. The movement of the vehicle then adds momentum to that tilt, exacerbating the situation. Also, if traversing a steep and loose slope and the vehicle starts to slide sideways and then catches grip again suddenly, or the downhill tires dig in, it's as if someone on the high side of the vehicle gave it a really good shove.

Negotiating a loose, sandy side slope in Peru above the Pacific. Even a relatively lightweight camper raises the center of gravity significantly.

In the syllabus for the N.P.T.C. (National Proficiency Test Council) certificate in four-wheel-drive proficiency, the guidelines for negotiating side slopes don't mince words: "Avoid if possible" is number one. But what other precautions should you take?

First make sure there is a recognizable track across the slope, to prove others have crossed it successfully. A well-used track also helps ensure there are no surprises in the substrate.

Follow the golden rule of handling any challenging situation in a four-wheel-drive vehicle: "As fast as necessary; as slow as possible."

Watch the placement of your tires to avoid low spots on the low side and high spots on the high side—especially rocks in the latter case, which due to suspension bounce can bump the vehicle farther over than the actual height of the rock.

Prep the vehicle in advance to keep the center of gravity as low as possible, especially if you're carrying gear on a roof rack. If I were forced to traverse a slope I felt was on the edge of safety, I wouldn't hesitate to add some air to the downhill tires and take some out of the uphill pair.

If you're on a side slope and the vehicle begins to slide sideways out of control, or heaven forbid, tip, the escape clause is to immediately turn downhill. Whatever danger you might face driving straight down that slope is nothing compared to barrel-rolling down it.

Just before you do that, though, check the tilt-o-meter so you'll know when to back off next time.

The 2019 Ram 1500

You know the world of pickup trucks has changed when the central multi-function touchscreen in your test Ram 1500 is as big as the computer on which you are writing the review of it.

Well, almost—my Macbook Pro’s display measures 13.9 inches—but trust me, the Ram’s optional 12-inch UConnect touchscreen looks massive embedded in the middle of the dash. And I’ll say right off, that screen propels the factory navigation system into a new universe of legibility (It also makes the five-incher on the base Ram look like someone glued a flip-phone to the dash).

Ram (or Dodge if you’re stubborn) trucks have come a long way since 1992, when the company showed a group of potential buyers prototypes of a truck styled like no consumer truck before it. It sported a front end that called to mind an 18-wheeler, with a tall bulging hood and dropped fenders incorporating the headlamps. According to legend, the reaction was starkly love/hate, and not reassuring: 86 percent of the viewers hated it, 14 percent loved it. The whole idea was about to be scrapped when someone in the marketing department pointed out that Dodge’s share of the American truck market at the time stood at about seven percent. The design was approved, and sales of Dodge trucks quadrupled in three years.

Two decades on, Ram trucks still trail Ford and Chevy but now claim a comfortable 22 percent share of the full-size market (compared with Ford at 44 percent and, for example, Toyota at an undistinguished five with the Tundra).

Still, third is two places behind first, and Ram executives would love to climb another 10 or 20 percent up that sales chart. The 2019 Ram 1500 launch in Scottsdale was the first salvo in what will be a rolling release of optional engines, followed at some point by the heavier-duty 2500 and 3500 models. The new truck has been comprehensively revised from the wheels up, and cold, hard sales figures will soon tell how well the redesign fares with the public. Our question here is, how might it fare with overland travelers?

The demographics of pickup buyers have shifted massively in the last few decades. It used to be you bought a pickup if you had stuff to carry—a lot of stuff, like construction materials, or, if you were an outdoorsman (and, yes, the operative syllable was overwhelmingly “man” back then), a camper. Or you had a trailer to tow. A pickup was a working vehicle. Air conditioning and cloth upholstery were luxury options. To unlock the passenger door you scooted across the seat and pulled up on the button.

Not any more. Ford now sells two and a half thousand F-series pickups every day, and while their ads still stress the manly aspects of pickup ownership, most of them never carry a load larger than a pallet of Costo toilet paper. The pickup is now a lifestyle choice much more often than it is a practical necessity, and increasingly the competition among truck makers is as much about making a pickup not feel like a pickup as it is about making it function like one.

I know what you’re thinking: Isn’t overlanding a lifestyle choice? Absolutely true; however, in our defense we do actually need the functional aspects of a truck—load-carrying ability, reliability, durability, off-pavement capability—as much as we secretly hanker after the non-truck-like aspects prioritized by the guy down the street who wouldn’t know a GVWR from a GMC.

I can loftily claim to be conversant in both aspects of pickup ownership: We use a Ford F350 to tow the 10,000-pound Overland Expo equipment trailer to the shows in Flagstaff and Asheville, while our Tacoma permanently carries a Four Wheel Camper. But I remain much less impressed by car-like interior features than by high-quality engineering. So let’s start with that—specifically, the chassis of the new Ram.

Naturally, it remains a fully boxed structure. (Toyota is the only manufacturer moving backwards in this regard, with its “Triple-Tech” design that leaves the rear third open-channel, to the detriment of chassis rigidity.) Additionally, the Ram frame now comprises fully 98 percent high-strength steel (not sure why two percent remains “normal” steel?). Crossmembers extend through the side members and are welded on both sides. The result is increased rigidity compared to the previous Ram, yet a full 100 pound savings in weight (FCA claims a total 225-pound weight savings for the new model). That stiff frame contributes to—depending on the specific option package—a maximum 2,300-pound payload and a maximum towing capacity of 12,750 pounds. (By way of comparison our 2004 F350—a one-ton truck, mind you—is rated to tow 12,000 pounds.) Wheelbases range from 140.5 to 153.5 inches.

The frame rails in front of the engine splay curiously outward at about a 15-degree angle, a feature Ram says helps with crash protection, and is patent-pending. Below those rails is another feature standard on all new Ram pickups: a composite air dam that lowers automatically at speeds over 35 mph to reduce drag. Lest you think that such insignificant details could hardly make a difference, note that the dam combined with the body design results in a drag coefficient for the new truck of just .357, the lowest of any full-size truck. By comparison, the drag coefficient of my 1982 Porsche 911SC is .40 (although it of course has a fraction of the frontal area, which must also be figured in to arrive at the total drag on the vehicle—but still . . .).

More chassis tidbits: A pair of discs that resemble weights for a barbell, on either side of the frame under the passenger compartment, are actually “active tuned mass modules” that reduce vibration, especially when cylinder deactivation kicks in on the V8. The transmission and front suspension crossmembers are aluminum. Steel bars behind each front wheel deflect them outward in the event of a frontal offside collision.

Below the chassis sits a suspension comprising either progressive-rate all-coil springs or an optional all-air system, a first in the pickup market. The air suspension combines automatic load-leveling with manual control—Ram engineers demonstrated one advantage of the latter by hooking up a trailer: The driver reversed using the backup camera, lowered the hitch by deflating the rear air bags, and once the ball was under the tongue simply raised them again, coupling the trailer and lifting the tongue jack off the ground—no cranking necessary. The height of the vehicle can also be adjusted for easier passenger entry or greater ground clearance. The springs combine with new “Frequency Response Damping” (FRD) shocks incorporating internal bypass valves to improve ride and made by, I believe, Hitachi. Go figure.

The five-link suspension on the rear axle has been updated for more travel. The front combines aluminum lower control arms with upper arms comprising steel and—ready?—structural composite. That’s right: plastic. The composite wraps the steel so it looks like there’s nothing but plastic in the piece, a slightly unsettling illusion.

Outboard of the front control arms are brake discs a massive 14.9 inches in diameter, the largest in the class. The parking brake on the rear discs is now electric—another bit of weight saving.

Are you getting my picture? Just as with the redesigned Wrangler I reviewed here, a substantial part of the Ram’s redesign took place in spots invisible under anything but an on-the-rack inspection—or on the exposed chassis FCA had displayed for us at the launch. It was impressive.

Less impressive, from a what’s-new standpoint, was the drivetrain—at least the engine, which, for this session was limited to the existing 5.7-liter hemi V8. The 5.7-liter eTorque and 3.6-liter V6 eTorque “mild hybrid” engines will be introduced later, although they were there on stands for us to admire.

Soon-to-come 5.7-liter eTorque engine. The eTorque module is the Ram-branded device at top front.

If you’ll allow me an aside on that heavily hyped “Hemi” engine: hemi is short for hemispherical, which refers to the shape of the combustion chamber in a hemi, almost literally a dome shape. The hemi head allows for very large valves, which are placed across from each other, with the spark plug in between. So it’s a good way to develop a lot of power (thus the mythology)—the catch being it’s a good way to develop a lot of power from a two-valve-per-cylinder engine. You can’t put four valves in a hemispherical combustion chamber—the angles would be impossible to manage. For a four-valve engine you need a pent-roof combustion chamber. And four valves are better than two at developing power. Thus, evaluated objectively, the hemi produces decent power while avoiding the complexity of a four-valve head.

Where was I? Right: The standard 5.7 (395 hp, 410 lb.ft.) is a fine engine, and moves the Ram along briskly with the upgraded eight-speed 8HP75 TorqueFlite transmission. Shifting on all these new multi-speed transmissions I’ve tried recently is so seamless they are difficult to critique. Downshifting for passing seemed to lag just a bit, otherwise the drive was faultless. If any cylinder deactivation occurred during my drive I didn’t notice it (it only engages in third gear or higher). I was impressed enough with my short experience in the Wrangler with its 2.0-liter, four-cylinder eTorque engine that I look forward to trying the larger versions. In the Wrangler the eTorque seemed to add noticeable torque right off the line, before the internal-combustion partner climbed into its own torque curve. The fuel economy of these engines might determine their reception in the market.

Okay, so let’s plop the body of this truck on that impressive chassis (let me tell you, it was really hard driving the truck without it). The first thing I noticed is that the 18-wheeler look has been smoothed over so much it’s simply not a feature any more. There’s still a prominent power bulge to the hood, but the headlamps are now even with the top of the grille rather than the bottom. I bet the stylists figured Ram has enough market presence now to stand on its own, so they went for a smoother, more aerodynamic front end. It’s attractive, but not as Smokey-and-the-Bandit butch as the original—you decide whether that’s good or bad. It seemed more grown-up to me, and I liked it.

The high-end option packages such as theLimited and Laramie Longhorn incorporate sleek LED headlamps that swivel with the wheels. Substantial recovery hooks peek out from nacelles in the bumper, whether chrome on the Laramie or matte on, for example, the trail-oriented Rebel.

My first interior experience happens to be with the Limited. I open the door, climb in, shut the door. I check the rear-view mirror: Yep, there’s a cargo bed back there. But I’m fully ensconced in the not-like-a-pickup end of the new Ram’s design. Want some details on how not-like-a-pickup it is? Consider these features:

- Leather—lots of it. Ram assures me there is substantially more than I could find in a Chevy or Ford.

- Seating. The seats recline. So what, you say? I’m referring to the rear seats. The front seats adjust a bunch of different ways, and they’re very comfortable, although, as with most seats these days, built for people significantly wider than I.

The Laramie Longhorn has slightly tacky alligator-pattern leather bits, but genuine wood trim.

- Quietness. How about active noice cancellation? Acoustic glass? Ram claims a 66.6 db cruise. I think our old F350 is louder than that parked. With the engine off.

- That giant uConnect touchscreen is surprisingly practical. First, there are redundant manual controls alongside it for the climate control and sound system. Three cheers, because no multifunction touchscreen will ever match the speed of reaching down and turning a dial. With that said, the rest of the touchscreen’s functions are easy to access; you can even split the screen into still-quite-readable halves. And in navigation mode it is simply brilliant. (The bird’s eye perspective is cool too.)

- Did I mention sound system? This one is a Harmon Kardon, with 19 speakers and a 10-inch subwoofer. The only downside is, it’s not removable so you could use it in the living room too.

- Driver-assist features: Adaptive cruise control, blind-spot monitoring, rear cross-path detection, brake assist, surround-view cameras.

- Parallel and perpendicular park assist. You work the gearshift, throttle, and brake while the truck turns the steering wheel to maneuver you into a parallel spot (on either side of the truck), or to back you into a perpendicular space. My question is: Would this count for a 16-year-old trying to pass a driver’s license test?

- There’s more, especially a bewildering array of interface possibilities, with Android Auto and Apple CarPlay, fourth-generation Sirius XM Guardian Connected Services, which can provide a 4G wi-fi hotspot, all controlled through the uConnect touchscreen. The truck sports a raft of USB ports, and an optional wireless charging station (which is labelled “Ramcharger”).

- On a more practical note for long-distance travel, the new Ram 1500 has a two-level glove box . . . and the most spectacular center console I’ve ever seen on a factory truck. It’s massive—Ram says it’s twice the size of anything from competitors and I believe them—and boasts so many sliding trays and bins you could lose a chihuahua in there. An iPad fits in a special pocket, there’s 110VAC power available—400 watts worth—cupholders, coin holders, and a “feature” that I have to say was the silliest on the entire truck: On the bottom of one hinged lid is an engraved contractor’s conversion chart with a ruler and compass. I strongly suspect every contractor in the country has this on his or her iPhone and does not need to look at the bottom of the center console for the info. It took five minutes for my eyes to roll back down.

Brilliant and massive center console, but . . .

Hmm . . .

On our paved drive the Limited exhibited genuine carved-from-marble solidity and a taut ride at least as good as that of the Nissan Titan XD I reviewed some time ago, which at the time I thought exemplary. And by golly the thing is quiet. It handled the short stretch of dirt road to our press lunch spot with barely any increased noise.

After lunch we took turns on an off-pavement loop course in several examples of the Rebel, the trim level I suspect many overlanders will gravitate to. In addition to LT275/70R-18 Goodyear Wrangler tires and Bilstein shocks (with external reservoirs on the rear), the Rebel gets an electronic locking rear diff, hill-descent control, a one-inch suspension lift (if you don’t get the air springs), and several skid plates. You also get an interior that is any color you like as long as it is red and black, with Goodyear Wrangler tread pattern embossed on the seat upholstery. You also cannot get the 12-inch touchscreen with the Rebel (yet, at least), although the smaller eight-incher is just fine unless you’ve been pre-prejudiced by the bigger one.

Interestingly, I was told that an “off-road” package incorporating most of the Rebel options will be available on other trim levels. If this is so, you could conceivably equip your leather-clad, 12-inch-screen Limited or Laramie Longhorn with the good stuff.

The driving course we were set loose on in the Rebel was clearly meant to be driven quickly, a suggestion many in the press pool took to heart, especially since there were several videographers along the way to film our prowess. I thought the format might have been a mistake, since the Rebel is obviously not intended or equipped to compete with Ford’s Raptor in the wannabe desert racer category. Indeed, the example I got, previously flogged by who knows how many hot-footed journos, displayed a worrying banging noise in the left front suspension area when pushed, so I took it easy. I later rode in the same truck and the new driver noticed it as well. (From a quarter view behind, I watched one truck on the course approach a “Slow Down!” sign warning of a sharp, angled pair of ditches where water had flowed into the main wash course. The driver didn’t lift off a bit, and the front suspension slammed to its bump stops and tossed the truck in the air. This is why manufacturers don’t think highly of most automotive journalists.) With that said, the Rebel would clearly be right at home exploring back roads at sane speeds, and capable with the locker and hill-descent control of going anywhere most overland travelers are likely to.

So . . . to that point, several things come to mind. First is wondering whether the optional air suspension has the capacity to compensate for the weight of, say a Four Wheel Camper, while retaining a decent ride when the camper is off. I asked of FCA, but the we-can’t-authorize-that liability/warranty clause kicked in immediately, which I more or less expected. The top-level 2,300-pound payload is technically up to the task of camper transport, but technical capacity does not always translate to practical (safe) capacity. Still, it would be worth the experiment, except if it didn’t work you’d have spent the extra money for nothing. Having to change out the air springs for coils to accept a camper would be at best expensive and at worst impossible. The air system is certainly adequate to handle lesser camping loads, or a rack carrying a rooftop tent, for example, while maintaining proper ride height and safe handling.

For general overland travel, the new Ram—in any of its guises but especially the Limited and Laramie versions—represents a new high water mark in the evolution of comfort in a pickup truck. After all, even for the most adventurous of us, 90 percent of our travel—even while actually on a journey—is usually on pavement. I’d think little of tackling an 800-mile freeway day in the new Ram to get somewhere interesting.

That brings up the subject of fuel economy. Numbers are not yet out for the eTorque engines, but for ultimate economy the answer will still be a diesel, and I did not hear any information about when (or, actually, even if) the new Ram will get one.

My lasting impression from both the Ram and the previous Wrangler launch is that FCA is genuinely throwing a lot of thought and engineering into its redesigned working vehicles. The new Wrangler retained its spot in my opinion as America’s own world-class expedition vehicle. I think the new Ram 1500 can stand confidently alongside America’s Big Two half-ton pickups, and all three are ahead of the import competition.

The JL Wrangler Part 2: Rubicon

Scuffing tires on the demo course. Matt Scott photo.

I wonder if any of the corporate liability attorneys who signed off on the Jeep Wrangler Rubicon’s front and rear diff locks, anti-roll-bar disconnect, 4:1 transfer case, and 77:1 crawl ratio were ever given a demonstration of the vehicle’s capabilities.

Probably not. “Oh, those modifications? They, um, just help traction. You know, to enhance safety,” the engineers told them, winking broadly at each other.

And in a very real sense the engineers were telling the truth—it’s just that they were referring to traction on, say, a 30-degree hillclimb studded with boulders the size of engine blocks. Which is where I found myself, with FCA’s Scott Brown in the passenger seat, in an arrest-me-if-you-can-follow-me-red two-door Rubicon, top removed and windshield folded down. The eight-speed auto box was manually selected to first in low range, anti-roll bar disconnected, and both diffs locked. I noted with approval that (along with the anti-roll bar switch) the JL’s diff-lock selector has been moved to the center of the dash for easy access (in a bright red escutcheon to boot), and hugely simplified from the JK’s: Push down for rear lock, up for front and rear. Amazingly, the new electrohydraulic power steering gave me zero indication that the front wheels were rigidly joined; normally a locked front diff firms up even power steering noticeably.

Much-simplified diff-lock control. "Sway bar" button disconects front anti-roll-bar.

Through the windshield there was a lot of blue Arizona sky, and spotter Jim Horne’s arms motioning me straight up, and up, and then left across the boulders. Scott and I transitioned from being pressed into our seats to being pressed, respectively, against the center console and driver’s door. The side/down slope was enough to make Scott give a little whoop of excitement, and for me to appreciate the integrated roll cage surrounding us. The Jeep, of course, was loafing, idling in that 77:1 crawl ratio at half walking speed, each BFG All-Terrain tenaciously gripping granite (the techs hadn’t even bothered to air them down). A turn right back towards the sky, a pause while Jim wedged an extra rock under the left rear tire, then we were over, and being waved on to the next obstacle by the next spotter. (That particular hill would shortly be closed down for rebuilding after another journalist repeatedly applying too much throttle while ignoring instructions managed to send a bunch of those engine blocks tumbling down the slope.)

Jim Horne guides a Rubicon Unlimited up the hill.

The JL Sahara Matt Scott and I had driven to get to the staging area had impressed me with its capability, and driver-independent traction-control systems are getting better with each generation. But the Rubicon is in a different universe. Even the best ABS-based traction control can’t match the ability to manually lock one or both axle differentials in advance of a limited-traction situation. Flip that center toggle switch upward in the Rubicon and you have Four. Wheel. Drive. Period. Combine that with the disconnectable front anti-roll bar, which hugely increases compliance—and comfort—on a rough trail, and a crawl ratio slow enough to let you watch cactus grow on your way past, plus excellent approach and departure angles (44º and 37º), standard BFG All-Terrains, etc. etc., and you have a vehicle unmatched by anything in its class in terms of backcountry capability—either in the U.S. or the rest of the world.

That much capability necessitates a strong foundation to withstand the stresses involved in powering a 4,300-pound vehicle up a torturous slope. While the JK Rubicon was more than up to the task, the JL raises the bar. The fully boxed chassis now employs 80 percent high-strength steel, with five boxed crossmembers. Torsional rigidity is up by 18 percent, yet, the factory claims, weight is down by 100 pounds. The next-generation Dana 44 axles have been improved as well: The front axle tubes are 10 percent larger in diameter, 14 percent thicker, and twice as strong as the previous versions. End forgings on the Rubicon are 11 percent stronger. Components no driver could ever notice have been studied, critiqued, and tweaked.

FCA's Scott Brown rides along. Matt Scott photo.

FCA’s introduction and their excellent driving course left little doubt that the JL Rubicon is everything the JK Rubicon was, and more. (Some might see the move from BFG Mud-Terrains to All-Terrains as a retrograde step, but it’s not. In a majority of situations not involving mud, ATs are the equal of if not superior to MTs. And the new tires certainly help reduce road noise, and definitely bump fuel economy.) So the Rubicon’s bona fides for competency in extremely rugged terrain remain unmatched by anything in its class. If you’re looking for a vehicle that can serve as a perfectly comfortable daily driver, then be nearly invincible for weekend explorations of any trail you have the skill to drive, it remains the icon.

The question is: If I were considering a Wrangler as an overlanding vehicle—that is, for long-distance, self-sufficient travel on a mixture of paved and dirt roads, with four-wheel drive sections definitely in the mix but little emphasis on difficult passages unless they were unavoidable due to route or weather—and if my funds were not bottomless, which way would I go? I evaluated two approaches, both of them the Unlimited (four-door) body style:

- Go basic and order a Wrangler Sport with suitable options. On FCA’s new Wrangler build site I specced a Sport with the same Pentastar V6 and excellent ZF eight-speed automatic transmission as the Rubicon, the standard black hardtop, Anti-Spin rear diff, all-terrain tires, and a few other relevant bits such as heavy duty electrics (240-amp alternator, 700-amp battery), etc., for $36,305. It would have the simple Command-Trac part-time four-wheel-drive transfer case with ABS-based traction control (which Jeep refers to as a differential brake). To be honest, this system is capable of handling 99 percent of the terrain I have experienced on extended journeys in South America, Australia, and Africa, even completely off-tracks forays into Egypt’s sand seas. (The Anti-Spin diff is designed to seamlessly handle slight differences in cross-axle traction; the more intrusive ABS- based traction control kicks in for more extreme variations.) Jeep lists the cargo capacity if the Sport at a middling 1,000 pounds, not including the driver. (One of the few disappointments of the JL redesign is the lack of a heavier GVWR option. I wonder if the upcoming pickup version will raise this.)

- Finance a bigger chunk and go for the Rubicon. In addition to the drivetrain and suspension features—4:1 transfer case, electric locking differentials front and rear, driver disconnectable front anti-roll bar, 4:11 diff ratios—the Rubicon boasts other standard features not available on the Sport: premium seats, an AC power outlet, a seven-inch touch screen, power heated mirrors, remote keyless entry, plus several premium options. I went through its build list, not going crazy with leather upholstery or any similar spurious extras, but nevertheless equipping it more upscale than the Sport, and came to $48,090. (I could easily have added another $4,000-$5,000 in bling.) Cargo capacity of the Rubicon is even less than the Sport—890 pounds.

Despite the slightly higher GVWR of the Sport, I’m pretty sure that for either vehicle I’d want heavier-duty rear springs and shocks if I planned on traveling with a passenger and a full load of equipment, food, and water. Even a load nearing but not surpassing the factory limit would depress the stock rear springs enough to upset the ride height and headlamp alignment. So that modification would cost about the same for either vehicle. Otherwise, what does one get for the extra $12,000 of the Rubicon besides—let’s not diminish this—the knowledge that anywhere in the world you traveled you would be able to tackle the toughest routes passable by any stock vehicle?

One answer worth considering lies in those next-generation Dana 44 axles, a significant step up in strength and durability from those fitted to the Sport. Note: I absolutely do not think the Sport is under-equipped in that category (as long as you don’t try to cram stupidly oversized tires on it), but the overwhelming priority for an overland vehicle is reliability and durability, and there is no doubt that the Dana 44s would optimize that in a Wrangler.

On the other hand, the higher (i.e. numerically lower) final drive ratio of the Sport—3.45 vs. 4.10—might make for slightly more relaxed freeway cruising at the expense of low-range crawling. However, with the eight-speed auto transmission on each, and taller tires of the Rubicon, I’m not sure how noticeable this will be, and I did not have a chance to directly compare the two, as I only had access to the Rubicon in the dirt.

Of course the extra comfort (I wouldn’t classify them as “luxury”) items standard or available on the Rubicon would make traveling a bit more relaxing.

In the end—and I hope this doesn’t sound like a copout—I would buy the Rubicon if I had the funds, and be completely happy with the Sport if I did not. In fact, I’d leave for a trans-Africa trip in either with no hesitation.

Remembering to pack carefully, of course.

Thanks for the photos, Matt!

Hint: When using “Search,” if nothing comes up, reload the page, this usually works. Also, our “Comment” button is on strike thanks to Squarespace, which is proving to be difficult to use! Please email me with comments!

Overland Tech & Travel brings you in-depth overland equipment tests, reviews, news, travel tips, & stories from the best overlanding experts on the planet. Follow or subscribe (below) to keep up to date.

Have a question for Jonathan? Send him an email [click here].

SUBSCRIBE

CLICK HERE to subscribe to Jonathan’s email list; we send once or twice a month, usually Sunday morning for your weekend reading pleasure.

Overland Tech and Travel is curated by Jonathan Hanson, co-founder and former co-owner of the Overland Expo. Jonathan segued from a misspent youth almost directly into a misspent adulthood, cleverly sidestepping any chance of a normal career track or a secure retirement by becoming a freelance writer, working for Outside, National Geographic Adventure, and nearly two dozen other publications. He co-founded Overland Journal in 2007 and was its executive editor until 2011, when he left and sold his shares in the company. His travels encompass explorations on land and sea on six continents, by foot, bicycle, sea kayak, motorcycle, and four-wheel-drive vehicle. He has published a dozen books, several with his wife, Roseann Hanson, gaining several obscure non-cash awards along the way, and is the co-author of the fourth edition of Tom Sheppard's overlanding bible, the Vehicle-dependent Expedition Guide.