Overland Tech and Travel

Advice from the world's

most experienced overlanders

tests, reviews, opinion, and more

The new Land Rover Defender . . . in brief

My full review of the new Defender is scheduled for the spring issue of Wheels Afield, and as that was contracted I can’t offer all my thoughts here. However, I can offer a few, and a general conclusion.

My basic conclusion (Roseann’s as well) is that if Land Rover had named this vehicle anything but “Defender,” Land Rover fanatics would have greeted it rapturously. It’s really only the heady baggage of that name that created the uproar.

Over the course of five days we employed it for everything from serious rock crawling to freeway driving, and everything in between. And it handled them all with more aplomb and balance than any vehicle either of us has experienced, including JLR’s own premium models.

How so? Because the Defender’s all-independent air suspension offers 90 percent of the highway comfort of the Discovery and Range Rover—in other words, lots—while clearly being more biased toward backcountry capability than either. Exactly what most overland travelers I know want. The superior ground clearance and approach/departure angles were apparent while maneuvering around and over boulders, while Rock Crawl mode on the Terrain Response menu provided plenty of traction. Yes, I would prefer a full manual front locker instead of the traction-control version supplied, but with the center and rear diffs locked there was never anything we couldn’t climb.

Styling? It will certainly never be mistaken for a Series II, but some of that was inevitable in this day of aerodynamics and safety systems. I still give a thumbs down to the Angry Birds headlamp look and the Martha Stewart sample swatch of body color stuck in the middle of the greenhouse.

All is forgiven once you step inside. A dashboard I never dreamed would make it beyond the prototype stage in fact went straight to production, and it is simply stunning. Bentley should accomplish such elegance in a dash.

More important, the cargo area with rear seats down is eminently practical—rubber matted and perfectly rectangular. There is just enough room for my 5’9” to lie down inside; if, for couple-only travel, you removed the rear seat squabs (the back edges of which protrude above the flat floor) you could easily arrange a platform six inches longer.

On the road any resemblance to the old defender vanishes. My test vehicle had the Ingenium 3.0-liter straight six (hurrah for straight sixes!), electric supercharged and turbocharged, with 395 hp and 407 lb.ft. The owner’s manual recommends “not driving for long periods above 100 miles per hour.” I’ll bet no warning like that has ever appeared in a Defender manual before.

Of course . . . sigh . . . the big question, as always with Land Rover, will be reliability. There have already been a couple of alarming experiences documented on YouTube and elsewhere. I’m praying to the overlanding Gods that the Slovakia production plant can exceed its predecessor in Solihull in this department. Yes, that’s right: The British icon is no longer built in Britain. Some will gasp in horror; some will think smart move.

I will say this: Roseann and I both agreed we’d be happy to own one.

As long as we got to keep our original one too . . .

One-Case Toolkit – Episode 3 – Tool Rolls and Cases (Online Workshop)

This is part three of the One-Case Toolkit series online. Please note we had some bandwidth and camera-quality technical issues on this recording, so parts of the over-head camera show-and-tell stutter a bit, but the information is solid!

Assembling a quality set of tools for a field repair kit is only half the job. For tools to function efficiently and make repair jobs easier, they need to be stored properly, in a way that protects them, reduces noise, and above all keeps them organized and logically accessible. In this segment Jonathan will discuss ways to do that, from Pelican cases to Wolf Packs to Zarges boxes, and a variety of tool rools.

An interactive Q & A session is included.

Length: 1 hour, including Q&A

Resources from the Episode:

Company websites:

http://www.adventuretoolcompany.com

http://www.blueridgeoverlandgear.com

Tool Storage Products:

Step22 Pangolin $145

Step22 Stingray box $85

ATC Wrench Roll $60

ATC Shop Roll $100

Blue Ridge Tool Bag $136

Blue Ridge Recovery Bag $70

7POverland sells their recovery kit in this bag https://7p.io

Socket rails: Amazon—Casoman 6-piece ABS socket organizer ($19.97)

Tools mentioned:

Hammer – https://www.parktool.com/category/tools

Ground cloth – Rescue Essentials QuikLitter https://bit.ly/2N56HmM

and https://www.blueridgeoverlandgear.com/collections/tools/products/trail-creeper-multi-mat

Nissan electric van camper concept

Nissan has introduced an interesting all-electric van in Europe, called the e-NV200 Evalia (why not just Evalia I have no idea). In its standard form (below) it looks good, and promises a range of “up to” a middling 187 miles.

Now the company has released images of a pop-top camper concept, shown adventuring in snowy conditions somewhere. Consider that for a moment. An all-electric vehicle obviously uses a lot of energy to heat the interior in frigid weather, which means that “up to” maximum range is going to be butchered. In fact one of the publicity shots shows a couple who look for all the world as though they’ve just awakened from an frigid night to find their vehicle stone-cold dead and immobile, and are dully trying to heat some water for coffee to stave off hypothermia while waiting for the concept vehicle’s roof-mounted solar panel to recharge the battery bank enough to drive home on—a process that shouldn’t take more than a week if they don’t turn on a single LED accent lamp in the interim.

However, in the next photo they look much, much happier—I suspect because in the meantime they’ve pulled out the front seats and burned them to warm up and/or signal for help.

Ah, well, I guess that didn’t work. Here they are preparing to attempt to ski back to civilization.

No word on when or if the Evalia will be released in the U.S.—or whether the couple survived.

The kerosene lantern . . . still perfect.

After a (very) leisurely holiday break, I thought I would bring in the new year with an eye-rollingly obvious metaphorical piece on camp lighting, symbolizing 2021’s new beginning in either calendar or political terms, or both if you prefer. (Edit: I started this piece before January 7. Perhaps I need to wait a bit before actually turning on any metaphorical lights in the darkness.)

This is a specific bit of camp lighting, however, and one we keep coming back to no matter how much we experiment with alternatives. I’m referring to the classic kerosene lantern (aka hurricane lantern or storm lantern).

The hurricane lantern—that is, the universal style you’ll recognize that incorporates a hollow tube on each side of the glass globe, and a perforated cap above—is not the simple device most people believe. It came about as a product of evolution and ingenuity.

The first moderately efficient oil lamp was invented by Francois-Pierre Aime Argand, the son of a Swiss watchmaker, in the late 1700s. His lamp employed a fuel tank at the bottom, of metal or pottery, with a wick controlled by a knob, and a glass globe to provide some protection for the flame. It was a huge improvement on earlier, open-flame oil lamps with no control, which flickered with the slightest air movement, but not very bright due to poor oxygen supply, and still susceptible to gusts of wind. Also, if tipped over or broken it could easily start a fire.

Later oil lamps incorporated perforated rings at the base of the globe, which allowed fresh air to enter at the base of the flame, creating a hotter and thus brighter light. These were still susceptible to gusts, however. These lamps are referred to as “dead flame” lamps, since they rely on a simple, unchanneled supply of air.

In 1869 a young man named John Irwin, whose father had complained about oil lamps that blew out, received a patent for the “hot blast” lantern, which employed hollow tubes arcing from the base of the burner assembly to the vented top. These tubes returned some of the heated air from the burning wick to the base, and by providing this draft-free supply almost completely shielded the flame from gusts or movement. Robert Dietz, a manufacturer of oil lamps in New York, quickly bought the rights to produce the hot blast lantern.

Four years later Irwin introduced the even more revolutionary cold blast lantern, which has survived nearly unaltered to this day. In a cold blast lantern, the hot air rising from the flame, which is depleted in oxygen, is vented away from the tubes, which draw in only fresh air to feed the flame, significantly enhancing efficiency. Another happy characteristic of the cold blast style is that if the lantern is tipped over, the flame extinguishes itself, an enormous benefit in safety. While Dietz makes a retro hot blast model, virtually all hurricane lanterns you find today are of the cold blast type.

The Dietz company went on to produce millions of cold blast kerosene lanterns, eventually starting production in China in 1957—at the time more in an effort to capture developing-world sales than to save production costs. As things turned out, of course, the China factory was the only one to survive.

Meanwhile, in 1877, a German silverware maker named Karl Hermann Nier started producing miner’s lamps and household lanterns. In 1902 he established the Nier-Feuerhand (literally, fire-hand) company and began manufacturing high-quality cold blast lanterns, incorporating many patented improvements along the way. By the 1930s the Feuerhand company was the largest maker of storm lanterns in the world.

The end of WWII changed that, as the family’s manufacturing facility was in Beierfeld, which became part of East Germany. The company’s machinery was confiscated and shipped to the Soviet Union, and the family fled to West Germany, where they eventually managed to resume production. Eventually rights to the name were bought by Petromax—a legendary maker of gas pressure lanterns. Todays’ Feuerhand company produces exactly one model, the #276 Baby Special, still made in Germany.

So . . . to our camp lighting—and, specifically, to our dining lighting.

Dining lighting is different than general camp lighting. We have an extensive collection of devices for the latter, ranging from plug-in 12V LED strips to rechargeable LED lanterns to propane lanterns to a pressurized white-gas Coleman lantern. The LED lamps are cold and harsh for atmospheric dining, and the pressure lanterns are too noisy at a small table. But candle lanterns, which we tried, are really not bright enough.

We were reminded about the correct way to do things by Graham Jackson and Connie Rodman, on a trip across Australia. We’d been experimenting with a (very nice) rechargeable LED lantern, but Graham and Connie had brought their customary kerosene lantern, and when both were put on a table the LED’s glow looked gruesomely sepulchral next to the golden yellow of the kerosene flame. We fixed things next trip by purloining one of the half-dozen Feuerhand lanterns we use for casual lighting at our off-the-grid desert place outside Tucson.

The Feuerhand #276 is Goldilocks perfect. It’s silent, casts a warm light exactly bright enough for comfortable dining and conversation without being glaring (look up and you can still see the stars), and simply adds a lovely comforting air to a camp meal. It’s not so big that it steals table space, yet runs for hours on a single fill.

Admittedly, a kerosene lantern is a bit more bother than a 12V appliance. It needs to be stored upright, and unless you’re also into charmingly obsolete brass camp stoves (more on that later), it takes fuel you can use in nothing else. But trust me, it’s worth it.

A wonderful source for kerosene lanterns and the history thereof is W.T. Kirkman, here.

The saga of JUE 477

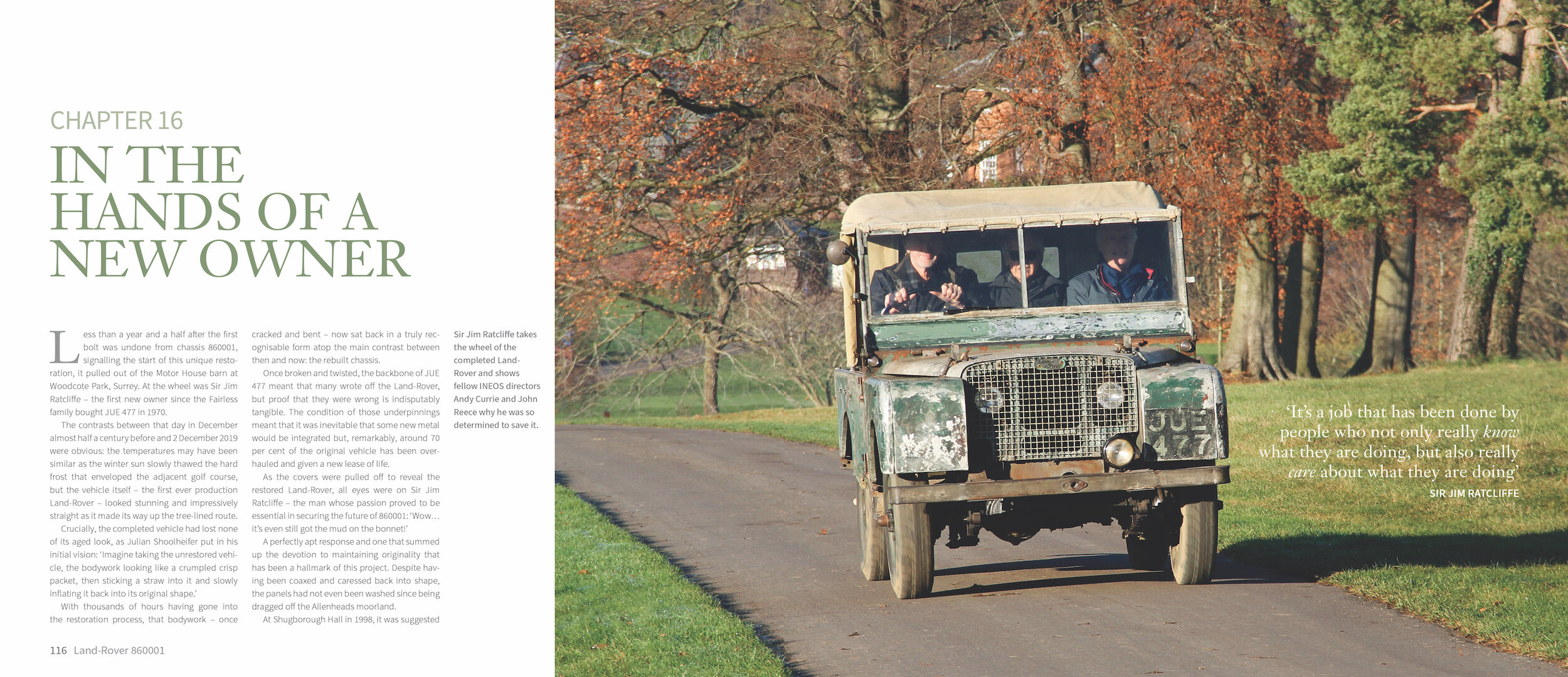

JUE 477 before . . .

The world almost lost this thing.

The very first production Land Rover, chassis number 860001, was earmarked to be presented to HM King George VI after it rolled off the assembly line in 1948. At the last minute, Rover Company officials decided it would be better to give him a later model, after any initial teething problems had been worked out. Instead, 860001 was handed over to a Mr. Searle within the company, probably to be used as a specimen for the first factory repair manual.

After this duty, 860001 was unceremoniously sold to a civilian, Professor Ewan McEwan, in 1950, registered JUE 477, after which it faded into obscurity and passed through several owners until, in 1970, a fellow named David Fairless noted in his pocket diary, “Bought Land Rover, £15.” Not a misprint.

Fairless used the Land Rover on his farm in Hexam, but at some point parked it in a field next to a stone wall due to mechanical issues.

And there it sat, exposed to the wet summers and harsh winters of northern England.

For 25 years.

The story of what follows is told—and superbly photographed—by Martin Port, in JUE 477—The Remarkable History & Restoration of the World’s First Production Land Rover, a copy of which is now in my bookcase.

In a supremely ironic twist of fate, JUE 477 was eventually purchased by Sir James Ratcliffe, the billionare CEO of the INEOS chemicals group, who has recently been making big waves with his Ineos Grenadier—a project unapologetically designed to envision what the next generation Defender might have been if its design had not constrained by corporate fealty to shareholders and the need to, above all else, be attractive to a wide range of customers.

From the hulk of what even to a Land Rover expert would have appeared a total loss, Ratcliffe’s team tackled what is without doubt the most intensive—and sensitive—restoration I’ve ever followed.

. . . and—yes—after restoration. Simply glorious.

It would have been easy to throw a new chassis, new panels and shiny paint, and mostly new parts on JUE 477, bolt in a few of the original bits, and call it a “restoration.” Instead the team went to extraordinary lengths to keep and repair as much of the original as possible. Eighteen months later, the result is, as the title of the book suggests, remarkable.

While JUE 477’s mechanicals were treated to a thorough rebuild to render it mechanically perfect, the team made the laudable decision to keep the Land Rover’s appearance as one might have expected had it been properly maintained but constantly used throughout its 72 years of life.

Astonishingly, despite the fact that the vehicle’s chassis had been sunk in acidic Northumberland soil for a quarter century, head restorer Julian Shoolheifer and workshop manager Richard Spikins were able to use at least some of every crossmember, main rail, and outrigger while welding in replacement bits. They straightened and reinforced the original Birmabright body panels—then left them exactly as they were, with splotches of the original Light Green paint showing through later splotches of Deep Bronze Green.

The finished JUE 477 is, simply put, perfect—infinitely more evocative and appropriate than a concours restoration would have been.

The book does suitable justice to the work of the team. Martin Port’s studio photographs could be framed and hung as art—or used as a detailed template for one’s own restoration. The description of the mechanical work, as well, could be a guide for what to look for and what to do if contemplating tackling an old Land Rover engine and running gear.

I like old vehicles of all types, and I’ve read and owned many articles and books covering restorations of classic Porsches, Triumphs, and other makes. I can’t remember one that achieved the same combination of description and illustration as Martin Port’s work. If you have the slightest practical or emotional interest in old Land Rovers, I recommend it most highly.

Porter Press is here. Also available on Amazon.

The turbodiesel Jeep Gladiator Rubicon in brief

It’s well-known I’m a huge fan of Jeep’s Wrangler Unlimited and, more recently, the long-anticipated Gladiator. I recently spent a week with a Gladiator Rubicon equipped with the 3.0-liter V6 turbodiesel, and I can say it’s made me even more of a fan.

The diesel is a significantly updated version of the engine that’s been available in the Ram pickup for several years. Among other tweaks, the block has been modified to reduce weight by 15 pounds while increasing stiffness. Power in the Gladiator is 260 hp and 442 lb.-ft., the latter available virtually full-fat from 1400rpm past 2800. Now that is a proper truck engine—none of this 4500rpm torque peak silliness common to so many gasoline V6 “truck” engines these days. It’s mated with one transmission, a superb ZF eight speed, honestly the only transmission it needs (I know, I know).

Besides effortless off-idle power in traffic and on 35-degree climbs alike, the turbodiesel returns excellent fuel economy. First I calibrated the computer’s fuel economy estimates the old-fashioned analog way and found them to be accurate within three percent. In a week of mostly around-town driving, plus a strenuous day of low-range use, the Gladiator turned a tick over 23 mpg. On the level stretch of 65mph highway out to our desert place, the computer bounced back and forth between 29 and 30mpg. That’s outstanding in a 5,000-poundish (with the 270-pound-heavier diesel) truck on 33-inch all-terrain tires.

Cynics point out how many hundreds of thousand of miles one needs with that economy to make up for the $4,000 premium of the diesel. They’re missing the point, which is that a high-torque turbodiesel is simply a better engine for a 4x4 truck, fuel economy notwithstanding. And once the pain of the initial price is gone, you’re still left with the long-term satisfaction of mid-size sedan frugality and a 500-mile freeway range.

Accepting the inevitable compromise in breakover angle of its 19-inch longer wheelbase (compared to a Wrangler Unlimited), the Gladiator diesel proved totally unflappable on a well-known four-wheel-drive circuit in Redington Pass east of Tucson. It even took the challenging Three Feathers rock face in stride, helped by excellent marshalling from my friend Brian DeArmon. Elsewhere, despite the wheelbase, I only made solid rock contact twice—and those were both on the front radius arm mount—user error as I came down off boulders too quickly. The center skid plate (which desperately needs a stouter aftermarket solution) only scraped lightly a couple of times.

The only downside to the truck I drove—and it is significant—is payload. The highest payload available in a gasoline-engined Gladiator is an okay 1700 pounds. The diesel in the Gladiator Sport drops that to 1,325 pounds, and the diesel/Rubicon option cuts it even further to a measly 1,075 pounds—not very much for a pickup. Subtract the weight of four occupants and you’re left with less than 500 pounds of actual cargo.

Personal opinion, not suggesting this, do not attempt at home: Given that the Sport and Rubicon share virtually everything load-capacity-oriented except springs and shocks, if I were lucky enough to own my test Gladiator and wanted to put something like an Alu-Cab shell on it, I’d have no hesitation in simply uprating the rear springs and shocks to handle the load.

In a world where proper body-on-boxed-frame, solid-axle, expedition-worthy 4x4s are disappearing, FCA continues to work magic on the Wrangler line, bringing it up to modern safety and comfort standards while retaining its capability, durability, and, last but not least, damn good looks.

Installing an external water tap

The camper conversion in our Toyota Land Cruiser Troop Carrier had one significant disadvantage: The closed roof covered the sink and water tap in the galley counter; to use it we had to raise the pop top. The Expedition Centre in Sydney had installed an extra water line from the chassis-mounted 95-liter tank to the rear of the vehicle, fitted with a simple twist valve, from which we could get water via gravity feed. However, it was extremely slow, and its parked position tucked up into the chassis was a pain to access and guaranteed it would be filthy—no help when you wanted to wash your hands. Also, a raised bend in the line meant that once the level in the tank dropped below half, we could get nothing out of it.

On our last trip across Australia, jealously watching Graham Jackson and Connie Rodman access pressurized water through a convenient tap at the back of their Troopy, we knew we needed a similar arrangement. With our Land Cruiser back home in Arizona I was able to tackle the task.

I bought a solid brass Wadeo rain barrel ball valve tap with a bulkhead fitting. Using this meant I would have a semi-permanent fitting in the bumper and an easily replaceable tap. I selected a spot on our Kaymar bumper where the tap would be well-protected by one of the swingaway latches from accidental impacts, then drilled through the (thick!) bumper and installed the bulkhead fitting and tap.

We’ve used Shurflo 12VDC pumps for the water system out at our desert property for years, with excellent results, so I ordered a model 4009-101-E65 on-demand pump. This is a fairly bulky unit, but I found a good mounting spot behind the Land Cruiser’s right rear wheel well, tucked up inside the fender area. There is flat sheet metal here, a void behind it where wiring runs for the vehicle’s tail lamps and rear window wiper, then the exterior body panel. With a right-angle drill I was able to make four holes to bolt the pump’s flexible bracket securely to the fender. Since the Shrflo pump is an on-demand unit and is self-priming, I was able to use the gravity-feed line to supply the pump, since it can draw water over the loop in the line to access water all the way to the bottom of the tank. A half-inch line runs from the outflow through the back of the Kaymar bumper to the tap.

A future addition might be a sheet-metal guard underneath the pump

Graham and Connie’s water pump had a master switch inside the vehicle, to prevent a mischevious passer-by from turning on the tap and draining the tank—an excellent idea. Our Blue Sea auxiliary power fuse block is in a recess in the cabinetry behind the (right side) driver’s seat. I grounded the water pump to the wheel-well sheet metal, and ran its hot line into the interior, behind the cabinetry up to the fuse center, and through a 20-amp-capacity toggle switch. Every point on the fuse block is utilized, so I simply siamesed the new pump onto the fuse for the sink pump, knowing that we’d never be using them simultaneously.

Interior switch prevents water theft. Fuse doubles for both inside and outside H2O pumps.

It’s a luxury to have on-demand pressure water outside, not only for washing hands and filling bottles, but rinsing dishes as well.

Brass cap keeps grit out of the tap.

EDIT: Reader Bill Ruttan kindly pointed out that on the Amazon ad he found for this tap, there was a warning that it was “not for potable water” as there is lead content. I looked back at the page from where I bought ours and found no such warning. Nevertheless, I found similar products that were certified lead-free, such as this one, so look for those rather than the one I got if you’re concerned about it. Will I bother to switch ours? Hmm . . .

One-Case Tool Kit – Episode 2 – Wrenches and torque wrenches (online workshop)

Part two in Jonathan’s series on his legendary One-Case Toolkit.

Don’t even think about using pliers on that nut. Aside from a socket, a wrench is the only proper way to fasten or remove a nut of bolt without damaging it. But what wrenches should you carry? How big should you go? What about ratcheting wrenches and box wrenches? We’ll also discuss torque “wrenches,” and why you should have and use one regularly.

RESOURCES FROM THE WORKSHOP:

OVERVIEW: THE CONTENTS OF THE ONE-CASE TOOL KIT

From the workshop chat, some of the products and tips mentioned by viewers:

Knipex pliers wrench solves most of the stated issues with adjustable size.

The original style beam torque wrenches weren't (aren't) ratcheting. That's probably where the name got set.

With a beam torque wrentch , one can measure the torque as one removes the fastener, in case the torque specifications are not available. I use it to measure torque while removing head bolts on a engine with a blown head gasket to pinpoint which head bolts are less tight and /or which cylinder could have issues.

I learned today to get a torque adaptor in order to save space. Thank you. Axle nuts may go up to 250 ft. lbs.

Okay, on a R1200GS the Rear wheel drive to swinging arm, M12 x 1.5 is 100 Nm (74 ft-lbs)

In aircraft accident investigation the torque to remove fasteners is routinely measured

Engine crankshaft pulleys will approach 250 ft-lbs also.

I believe break away torque when loosening a nut is typically higher than the original tightening torque. So I’d be careful trying to determine appropriate torque that way.

Tech engineer here, a good factory torque spec will assume a level of cleanliness and thread treatment. more friction in the threads mean you need more torque to achieve a given tension. most anti seize will lower friction and thus torque required compared to dry. but if manual says to anti seize and torque to x, hopefully the engineer already accounted for it and you don’t need to adjust.

http://www.torque-rod.com/

My experience with the torque rod is they are not very accurate. I was tested them on a machine in my lab, I would not trust them.

For fasteners without factory specs available, there are tables of standard torques that have different values for different thread lubrication conditions. Bossard has a good fastener handbook PDF you can find online for metric ones.

I love my Knipex pliers, very durable and user friendly. Always get More tools.

I've seen some tables where based on fastener size there are (typical) applicable torque specifications. There's a DIN standard, if my memory's not wrong.

‘Load indicating washer’ are the ones that squirt at right torque. Hardish to find in metric sizes in small QTYs in US

Hint: When using “Search,” if nothing comes up, reload the page, this usually works. Also, our “Comment” button is on strike thanks to Squarespace, which is proving to be difficult to use! Please email me with comments!

Overland Tech & Travel brings you in-depth overland equipment tests, reviews, news, travel tips, & stories from the best overlanding experts on the planet. Follow or subscribe (below) to keep up to date.

Have a question for Jonathan? Send him an email [click here].

SUBSCRIBE

CLICK HERE to subscribe to Jonathan’s email list; we send once or twice a month, usually Sunday morning for your weekend reading pleasure.

Overland Tech and Travel is curated by Jonathan Hanson, co-founder and former co-owner of the Overland Expo. Jonathan segued from a misspent youth almost directly into a misspent adulthood, cleverly sidestepping any chance of a normal career track or a secure retirement by becoming a freelance writer, working for Outside, National Geographic Adventure, and nearly two dozen other publications. He co-founded Overland Journal in 2007 and was its executive editor until 2011, when he left and sold his shares in the company. His travels encompass explorations on land and sea on six continents, by foot, bicycle, sea kayak, motorcycle, and four-wheel-drive vehicle. He has published a dozen books, several with his wife, Roseann Hanson, gaining several obscure non-cash awards along the way, and is the co-author of the fourth edition of Tom Sheppard's overlanding bible, the Vehicle-dependent Expedition Guide.