Overland Tech and Travel

Advice from the world's

most experienced overlanders

tests, reviews, opinion, and more

Anti-Gravity Batteries' Battery Tracker

I’m not much of a mobile phone person—in fact I hate the things and would happily revert to a black Bakelite dial phone in a little nook in the hallway. But such is no longer the way of the world.

One bright spot of the new world is the availability of apps, which tend to be far more useful than the average actual phone call. I have the Star Walk astronomy guide—which is pure magic—and a bird guide that not only has descriptions and photos but will play the bird’s song for you. Brilliant. Motion-X GPS of course, and several practical tools such as inclinometers and an OBDII reader.

But way too many apps seem to exist just because they can. I recently got an otherwise excellent LED flashlight to review, the programming of which is accomplished with an app. Seriously? I need to clutter my phone with another program just to tell my flashlight whether to come on bright or dim when I push the button? Absurd.

Thus—even though I’ve been a fan of Anti-Gravity Batteries and their superb Micro-Start since the beginning—I wasn’t sure about their Battery Tracker, which is also paired with an app. Nevertheless I decided to give it a try.

The Battery Tracker is designed to let you monitor battery status via a smart phone. Okay, let’s see how it works.

Well, it works about as simply as one could imagine. Use your smart phone to scan the squiggly square thing on the package. (Roseann chimes in: “Uh, that’s called a QR Code, Mr. Gates.”). And bink, there’s the (free) app. Hook the wires on the tracker to the positive and negative terminals of the battery, and you’re done. The phone pops up with the voltage. I was disappointed the tracker didn’t come with a penny’s worth of double-sided tape to adhere it to the battery, but we had some.

Okay, battery voltage. Wirelessly. I can check it from the living room. I still wasn’t really getting it, so I kept reading the instructions. Aha: you can set the tracker to send you an alert if your battery’s voltage drops into the danger zone. That’s cool. It will also run a cranking test and a charging test to confirm adequate starting power in the battery and adequate charge from the alternator. Definitely a smart thing to do before a major trip.

And yet. I still wasn’t quite fully sold on it for my own use.

Finally I realized the problem. There was nothing wrong with the product; I was just using it on the wrong battery. I swapped it from the starting battery to the auxiliary.

Suddenly it was brilliant.

Our auxiliary batteries are the ones that are working all the time, to run fridges, lights, chargers, and inverters. Some of us install voltmeters in the system to monitor them, but you need to get up from the Kermit chair and go look at it, leaving your campmates ample time to steal your drink and gorge on the snacks. Others of us simply guess how long we can go without charging until the low-voltage cutout on the fridge kicks in. Now a simple glance at the phone will tell you if it’s time to re-orient the solar panels or go for a drive. And the tracker can alert you before the beer gets warm.

But that’s not all. The tracker can give you a 31-day record of charge condition. This would be perfect when setting up an auxiliary battery system, especially with solar input. You can determine if the all-important float voltage is being reached every day—critical to long battery life.

At $36 the Battery Tracker is reasonably priced, and could be used to significantly extend the life of your auxiliary (or main) battery, saving its cost several times over.

Anti-Gravity Batteries is here.

Not so simple: The simple redirected winch pull

Take any reasonably comprehensive winching course and, once you’ve covered the basic single-line pull, you’ll be introduced to the snatch block—or, more recently, its elegant one-piece alternative, the billet-aluminum recovery ring.

A pulley—which is what both devices are—serves a couple of purposes in a winch system. Most impressively, when a winch line from a vehicle is led through a pulley attached to an anchor and then back to a recovery point on the vehicle, the power of the winch is essentially doubled (minus minor frictional losses) while line speed is halved. (A corollary to this is that by pulling more line off the winch to rig a double-line pull, you are further increasing the power of the winch by reducing the layers of line on the drum. Thus you receive a double benefit during a difficult recovery.)

The other valuable use of a pulley is to redirect a pull—around a corner as it were—when a straight one is either awkward, dangerous, or impossible. It’s frequently used to recover a bogged vehicle when a recovery vehicle equipped with a winch cannot be positioned directly in front of it. A suitable anchor such as a tree is employed as a redirect point, using a tree strap and a pulley.

When you learn how to rig a redirected pull you’ll also learn that this use of a pulley does not multiply the power of the winch, nor does it halve the line speed. The easiest way to figure out whether or not you are multiplying winch power in any situation is to count how many lines are shortening when you engage the winch. For example, in the illustration below labelled Double-line Pull, both the line from the winch to the pulley and the line from the pulley back to the vehicle will shorten as the winch pulls, thus the power is multiplied by two.

On the other hand, in our simple redirected-pull scenario above, only the line running from the pulley to the bogged vehicle will shorten—the distance between the pulley and the winching vehicle will not change. Therefore the winch is operating at its rated power.

But now comes the not-so-simple part. What about the load on the anchor?

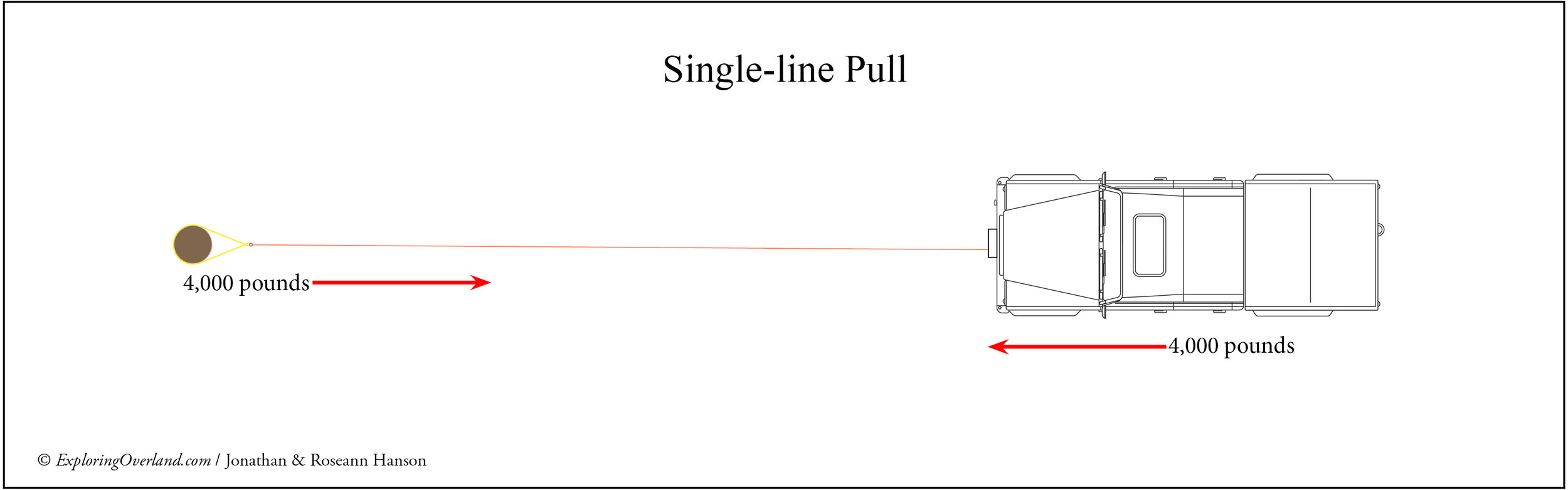

Let’s assume that in all our scenarios, the bogged vehicle needs 4,000 pounds of pull to retrieve it. If the operator rigs a single line pull to the tree anchor directly in front of the vehicle and engages the winch, the load on both the winch and the tree is 4,000 pounds.

If the operator rigs a double-line pull, the vehicle still needs only 4,000 pounds of pull to move. Due to the effects of the pulley the load on each line is halved, to 2,000 pounds; thus the winch is only exerting 2,000 pounds (and only drawing the amperage necessary for that), and the recovery point on the vehicle is also experiencing 2,000 pounds of force. The load on the anchor remains 4,000 pounds.

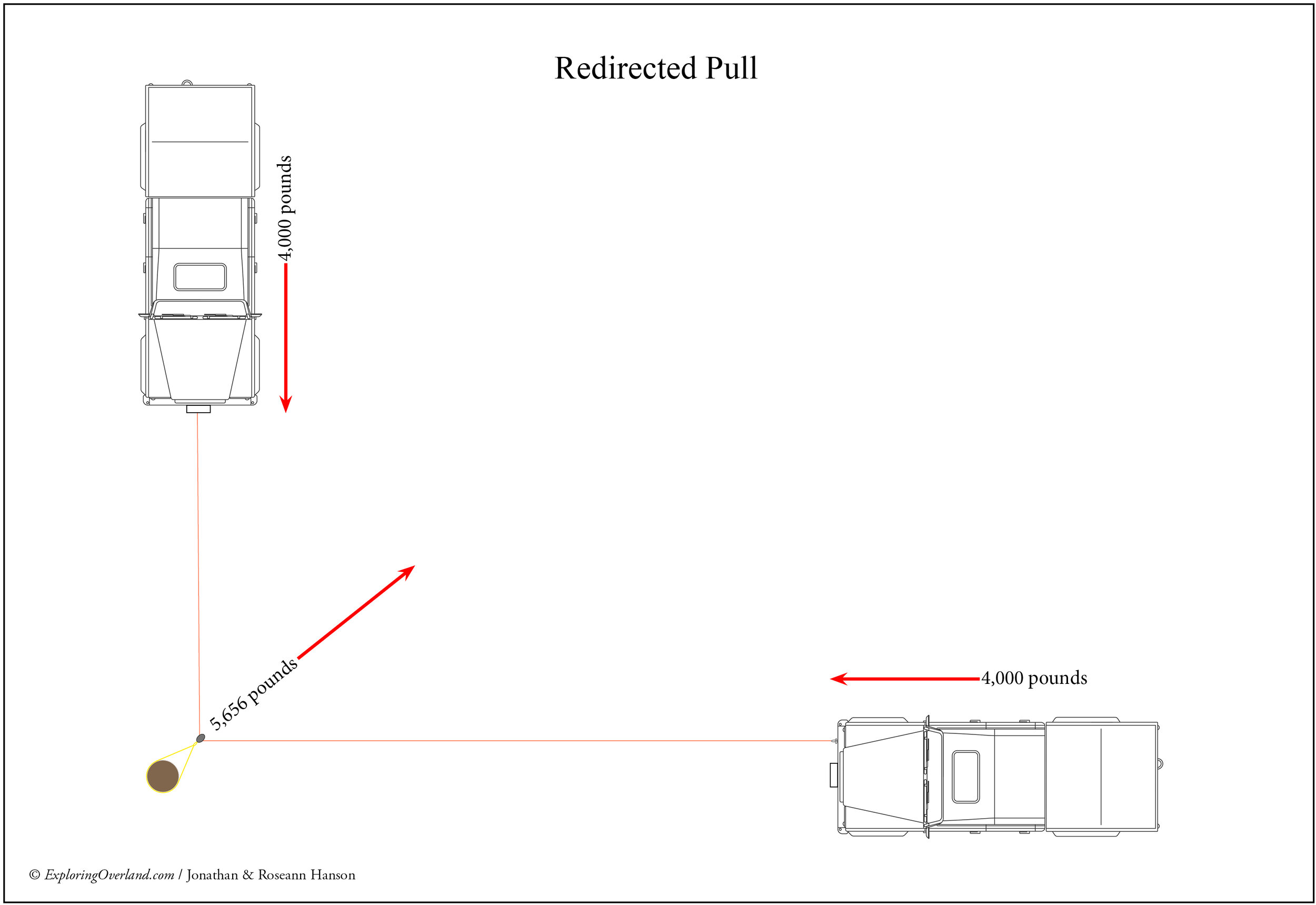

So far so good. Now let’s take another look at our redirected pull, where one vehicle is at 90 degrees to the other. In this scenario, the bogged vehicle still needs 4,000 pounds of force to move. The winch on the recovery vehicle is also subjected to 4,000 pounds—again taking into account slight frictional losses. So the force on the anchor must also be 4,000 pounds, right?

Actually . . . no.

In this case—a 90-degree redirected pull—the force on the anchor will actually be 5,656 pounds, almost 50 percent higher. The force is calculated using the formula:

pull = 2t(cosine x)

. . . where pull is the force on the anchor, t is the force exerted by the winch, and x is one half the angle at which the winch line passes through the pulley (in other words, the direction in which the anchor would move if it failed; in a 90-degree redirect it would be 45 degrees).

So, in our case, 2 x 4,000 pounds is 8,000, multiplied by the cosine of 45º which is .707, equals 5,656 pounds.

There’s more. As the angle between the bogged vehicle and the recovery vehicle narrows, the force on the anchor continues to increase. Imagine the scenario below, in which the recovery vehicle has to be situated directly alongside the bogged one—I’ve been in this situation. In this case, with the angle between the winch lines near zero, the force on the anchor would be (very nearly) doubled, to 8,000 pounds—even though the bogged vehicle is still only subject to 4,000 pounds of pull to free it. Imagine a tougher scenario in which the recovered vehicle took the full might of, say, a 10,000-pound winch to free it. In such a case that pine tree you wrapped your strap around is going to have about 20,000 pounds of force trying to pull it over—and all the hardware attached to it will be subject to the same stress.

You don’t actually have to have a calculator with a cosine function to figure the increase in force if you use a chart such as this, where “factor” equals how much the force on an anchor is multiplied by different angles of redirected pull :

And, in reality, you don’t need to do any figuring or checking at all. All you need to remember is that in any redirected pull, the force on the anchor can be up to twice what the rest of the system is subjected to. And the anchor includes the tree or chocked vehicle or whatever you are rigging to, as well as the tree strap, shackle, and pulley in the anchor assembly.

Non-instinctive effects of physics such as this reinforce the axiom always to use recovery equipment rated for the vehicle and winch, with working load limits (WLL) clearly marked, and adequate safety factors.

Learn how to winch online! Or not.

The greatest thing about the Worldwide Web is the vast amount of information accessible with a few clicks of a computer mouse.

The worst thing about the Worldwide Web is the vast amount of mis-information accessible with a few clicks of a computer mouse.

As part of my explorations of the online overlanding world, I occasionally browse through instructional YouTube videos, and I am frequently reminded how many of them should be called “instructional” videos. Sometimes the information in the latter type is harmless. Other times it is decidedly not harmless. That especially applies when the “instruction” is about winching.

Consider the video I have bookmarked in which the host attempts to demonstrate the party trick of moving a vehicle backward with a front-mounted winch. In essence this is a simple and virtually worthless procedure that involves running the line from the winch through a snatch block anchored to a tree in front of the vehicle, then to another attached to a tree behind the vehicle, then back through a third snatch block mounted on the vehicle’s rear recovery point, and finally to an anchor. When the winch is engaged the mathematics of the line being pulled results in the vehicle moving slowly backward. Aside from the fact that very few of us carry three snatch blocks, the odds of anchors being in exactly the right spot to rig this system where you might get bogged are scant. Our host got around the problem of multiple snatch blocks by simply using shackles instead—with steel winch cable. Ouch. He also utilized a child’s car seat as a winch line damper. Needless to say his attempt failed. However, the furthest anyone really needed to go with this “instructional” video was a glance at the fellow’s “spooled” winch cable.

A rat’s nest just begging for a snarl or jam.

In another demonstration of reverse winching, a cheerful Aussie bloke uses a kinetic strap as a tree saver—pretty much the most egregious never-do-this move you can make when rigging a winch recovery.

However, a recent video I watched, from Bold Canyon Outdoors, was in a way even more confusing, as it boasted decent production values, a well-spoken host, and significantly better equipment. The video offered a basic guide to winching, including a single, double, and triple-line pull.

It started out with a bit of humor, which was fun. But after the host brought out the winch kit he was using—and heavily promoting—from a company called Gear America, and began discussing the procedure, things began to go south. If I went through the video again I could probably pick out more goofs, but what I noticed immediately included the following.

First, he simply introduced a Jeep Wrangler with a winch. He said nothing about winch selection, sizing, mounting—the winch was simply there, taken for granted.

Then, when he introduced the “Gear America Ultimate Winching and Rigging Off Road Recovery Kit” (yes, really), he made no mention of matching the kit to the winch, no mention of working load limits (WLL) or minimum breaking strength (MBS) of the shackles or snatch block. He pulled out a “tow strap” included in the kit. Was it truly a tow strap, or a kinetic-recovery strap? Big difference. You can use an elastic recovery strap to tow with, but it would be dangerous to use a non-elastic tow strap as a kinetic recovery strap. He referred to the bow shackles in the kit as D-rings—not a big deal, you might say, but the little mistakes and omissions were quickly adding up to a not-very-credible presentation.

When the host ran the winch line out to a tree to use as an anchor, he mentioned nothing about choosing an appropriate (i.e. live and large enough) tree to take the strain. He also, critically, failed to check overhead for dead limbs that could be dislodged by the stress of winching. He properly employed a tree saver strap, but positioned it above waist height. A tree strap should be positioned as low as possible to reduce stress on the tree. Finally, when he connected the winch line to the tree strap with a bow shackle, he specified that the shackle pin should be “snug”—an elementary beginner’s mistake. A shackle pin should be snugged, then backed off a quarter turn or so. This is not a safety issue, but a way to ensure the pin doesn’t jam under load.

He then properly advocated employing a winch line damper to help control a recoiling line if a component in the system breaks. He placed the weight in the middle of the line. This is a small point, but I prefer placing the damper closer to the end of the line where the shackle and winch hook are—those are the heavy bits that represent the most danger should either or both come loose.

Next the host demonstrated a double line pull. While doing so, he introduced the Gear America snatch block, and noted that it is “suitable for either synthetic or steel winch line.”

Ugh.

The Gear America snatch block has a steel pulley with what looks like a standard semi-circular groove for the line. That’s perfectly suited for steel cable. A snatch block for synthetic line should ideally have a composite pulley. More to the point, while the steel Gear America pulley could be used with synthetic line, you would certainly not want to do so once it had been used with steel cable, and you most definitely would not want to swap back and forth. Steel cable will leave micro-abrasions on the pulley that are not good for synthetic line. (For the same reason, a winch fairlead—whether hawse or roller—that has been used with steel cable should be replaced if synthetic line is installed on the winch.)

I looked up Gear America, which seems to specialize in low-cost recovery equipment. The “Gear America Ultimate Winching and Rigging Off Road Recovery Kit” actually comprises a pretty basic assortment of kit, including what the website lists as a “tow strap.” Hmm. So I looked up that product separately, and found its description: “Use it as a Tow Strap, Recovery Strap, Tree Saver Strap or Winch Extension Strap, making it an extremely versatile product.”

Oh brother.

I looked at the construction, which is polyester, meaning there will be very little stretch in this thing. Therefore the suggested use as a “recovery strap” is highly problematic, since a recovery strap is commonly made from nylon and designed to stretch and absorb shock when it is used in a kinetic recovery. A novice who had looked at just enough YouTube “instructional” videos to have a vague idea of how to snatch a stuck vehicle could easily break something or rip off a bumper by backing up and taking a run at moving a bogged vehicle with this “multi-purpose” strap. At least the site lists the MBS and WLL of the strap (35,000 and 12,000 lb).

Next I looked at the bow shackles included with the not-going-to-write-it-all-out-again recovery kit—which are actually described there as “D-ring shackles.” They’re 3/4-inch versions, a standard size in thousands of recovery kits, and properly stamped “WLL 4 3/4T,” or 9,500 pounds. With a standard six-to-one safety factor on shackles that works out to a 57,000-pound MBS. However, the description right under the photo of the shackle and its stamp says it has a “10,500-lb WLL and 58,000-lb MBS.” Hmm . . .

9,500 pounds? Or 10,500?

Not to worry about math. Below that is the assurance that you can:

MAKE A BOLD STATEMENT - Our Unique Design Ensures Unprecedented Strength and Looks Amazing on your Jeep or Tuck (sic).

Lastly I looked at the Gear America snatch block, and sure enough it’s listed as being suitable for both steel and synthetic line. Also, the snatch block itself is labeled “9 US ton,” while the description below it says it has a “10,000-pound working load limit,” and an MBS of 10 tons. So . . . which is it, guys? Further, it appears there is no WLL indicated on the product, which could lead a user to assume the “9 US ton” refers to a working load limit—a dangerous assumption.

My impression of the Gear America site, I’m afraid, is that is was conceived and created by some people who thought selling 4x4 recovery gear would be a good business, but who have very little experience with actual 4x4 recovery. Either that or they handed off their website design to someone with no clue, and didn’t do any fact-checking.

Going back to the Bold Canyon Outdoors video, I realized the host was simply parroting most of what the Gear America advertising stated regarding their products. But that’s no excuse: If you’re going to post an “instructional” video that involves a potentially hazardous activity (the one in question has had 8,000 views), you really should strive to get every detail correct.

The ARB Pure View 800 flashlight . . . up to standard?

Anyone who has read my equipment reviews over the last 15 years knows I’m a loyal fan of the ARB line of products. My FJ40 Land Cruiser has worn Old Man Emu suspension and IPF driving lamps for at least a couple of decades, and more lately has an ARB locking rear diff and High Output compressor, plus a branded fridge—and I replaced the IPF lamps with ARB’s superb Intensity LED units. Our Tacoma has an ARB winch bumper and rear diff. The Land Cruiser Troopy we recently shipped to the U.S. from Africa is fairly bristling with ARB equipment, from the front bumper and Intensity driving lamps to the ARB Twin compressor and more.

Rather incredibly—or perhaps not—not a single one of those items has ever failed.

Even though I’m lucky enough to have been sponsored for much of this later equipment, my respect for ARB’s products came about through a straight retail relationship. The first OME suspension I installed on the FJ40 cost significantly more than those offered by other makers, but the company’s reputation convinced me it would be worth the extra cash, and that indeed proved to be the case, as it was with the then-state-of-the-art halogen IPF lamps. Every ARB product since has thoroughly proved its value-for-money to me before I recommended it to others. Still, someone who simply chanced on all our vehicles lined up could be excused for thinking I’m a secretly paid shill for the company.

Now, however, I have in front of me the new ARB Pure View 800 flashlight, which I’ve been using for a month or so. And for the first time, my reaction to an ARB product is basically a shrug of the shoulders. Not that it is by any means a bad flashlight; it simply breaks no real new ground and includes no genuinely outstanding features (well, one, which I’ll get to).

The 800 refers to the flashlight’s maximum output of 800 lumens—an astounding figure just five years ago, but today merely good (and no doubt accurate—many of the claims you see for cheap internet flashlights are wildly exaggerated). The pattern is just about perfect—a penetrating central spot with an even cone of more diffuse illumination surrounding it. Clicking (or half-pressing) the large rear “tactical” switch again gets you a 400-lumen beam, another step goes to 200, and another to a strobe. Running time is claimed, in order, as “up to” 1.5, 4, 7, and 24 hours (although why one would want to leave a strobe on for 24 hours is beyond me). These strike me as no more than ordinary run times despite the chunky body of the Pure View and its lithium-ion battery. But at least it’s rechargeable.

I also have an issue with the circuitry in the switch. When you turn the light off for more than a few seconds, it reverts to the highest setting rather than staying where you left it. So if you turn it off on low in your tent before going to sleep, then turn it on in the middle of the night for a toilet excursion, you and any tent-mate will be blinded by the 800-lumen beam. I’d rather have the option of choosing my own setting. Additionally, I do not recall ever using a strobe function on any of the three thousand flashlights my wife claims I have owned (it’s no more than two thousand). I would have much preferred a 10 or 15-lumen low beam suitable for reading or walking around, one that would have then had a run time measured in hundreds of hours. The 200-lumen “low” setting is far too bright for reading or looking at a map, or even most camp chores.

The Pure View charges via a micro-USB port cleverly hidden behind a rotating collar, which keeps it dust-free and dispenses with the usual rubber plug that inevitably breaks. Nice. However, when charging you must remember to turn on the flashlight before plugging it in, at which point the lamp goes off and a red “charging” light surrounds the charging port until a green “charged” light replaces it. If you forget to turn on the light, you’ll get a false green “charged” light but the light will not in fact be either charged or charging. Charging time is slow—four to five hours, limited by the capacity of the micro USB—yet ARB warns not to exceed six, so you should not simply leave the light plugged in overnight to charge. Incidentally, that outstanding feature I mentioned? It’s the included charging cord—a red-and-black fabric-wrapped cable of superb sturdiness and style. I’m actually considering ordering spares for my other micro-USB appliances. (The included belt holster is also excellent.)

Just as I was becoming concerned that I might be being too hard on the Pure View, I was walking along with it dangling by the lanyard when one end of the lanyard pulled free of its plug and the flashlight whacked to the ground (with no damage). But really?

Don’t get me wrong—the Pure View is a fine flashlight I’ll be happy to keep around. And—importantly—it’s priced very competitively at $57, with a two-year warranty (one year on the battery). But, unlike so many of ARB’s other products, it does not stand out from a crowded field. And until the company adds a true low-power setting (an easy modification, I suspect) I wouldn’t recommend it as one’s only all-around flashlight.

The big question: roof tent or ground tent?

The sleek but expensive Autohome Columbus in carbon fiber

Of all the requests for advice I receive, only choosing a vehicle seems to create more angst than the question of whether to buy a roof tent or a ground tent.

In simple economic terms this makes sense, since—especially if you decide on a roof tent—the outlay will likely be second only to the vehicle in terms of the hit on your overlanding budget. In fact I know people who have accomplished major journeys in vehicles that cost less than several roof tent models I can name.

But it’s also an important “lifestyle” choice, if you will, since carrying, deploying, and living with and in a ground tent is an entirely different proposition than doing so with a roof tent—even a roof tent with an add-on ground-floor room (or “mullet,” as a friend nicknamed the dangling appendage). So let’s look at the pros and cons of each.

Cost. Easy win for the ground tent here. The least expensive, made-in-China, soft-shell roof tents nudge $1,000. Premier products from Eezi-Awn, Tepui, iKamper, and others frequently top $3,000. And the size medium carbon-fiber hard-shell Columbus from Autohome will set you back a palpitation-inducing $5,600. By contrast, a 10’x10’, made-in-the-U.S. Springbar Traveler ground tent, one of the finest portable cabins on earth, costs $950. The 8’x8’ Turbo Tent Pine Deluxe 4 (from China), one of my favorite standing-headroom ground tents, is $495. And if you’re on a budget and don’t need standing headroom, there are dozens of options starting at under $200 from companies such as Slumberjack and Sierra Designs.

Classic, comfortable, and durable: the Springbar

Weight. Another win for the ground tent—with a couple of footnotes. That $5,600 carbon-fiber Autohome Columbus still weighs 92 pounds—and you’ll need a roof rack sturdy enough to support that weight while in motion and another 250-300 pounds when occupied. The soft-shell Front Runner “Featherlight” weighs 88 pounds. Larger and more feature-laden soft- and hard-shell roof tents typically weigh between 150 and 200 pounds. On the other hand, the 10’x10’ Springbar ground tent, made from substantial canvas and supported by substantial poles, weighs 62 pounds including poles and stakes. The 8’x8’ Pine Deluxe Turbo Tent weighs 42 pounds. Many other ground tents with as much interior volume as a large roof tent weigh less than 15 pounds. It’s true that roof tent weight includes a mattress, but that’s a matter of, at most, ten pounds.

The footnotes? Obviously the 62 pounds of the Springbar, or even the 42 pounds of the Pine Deluxe 4, is weight you’ll have to wrestle every time you pitch it—not so with a tent attached to the roof. Mount it once and forget it (unless you need to remove it between trips, either for handling and fuel economy or to avoid looking like an OVERLANDER every time you go grocery shopping). Importantly, the added weight of the roof tent is positioned in the worst possible place to add weight. Trust me that a 150-pound roof tent on an 80-pound roof rack will result in a noticeable difference in the on-road handling of even a substantial vehicle, and will make side slopes on trails more interesting.

Room. A runaway win for the ground tent. Even the most humongous roof tent is no larger than a good-sized backpacking tent. There are no roof tents with standing headroom for anyone taller than a four-year-old. Even a “mullet” only adds what is essentially a changing room. By contrast that Springbar Traveler will accommodate two full-size cots, plus a table and chairs or two smaller kid’s beds. You say you’re six foot five? You’ll still be able to stand up inside. The Pine Deluxe 4 is actually even taller at the peak.

In inclement weather, when you might be stuck inside during daylight hours, the contrast is even sharper (unless you’ve masochistically confined your ground tent to a backpacking model). Inside the 100 square feet of the Springbar you can walk around, sit across from your tentmate at a table to play cards or work, or catnap. Your luggage is out of the way under your cot. Cooking inside is easy. You can warm the space with a portable propane heater.

A Pine Deluxe 6 Turbo Tent, 10 feet square

Pitching. This is not as simple a question as it seems. Ground tents are intrinsically more involved to pitch, given unpacking and unfolding them, staking, running guylines, installing a fly, assembling cots or inflating mattresses, etc. Some are faster than others—the canopy of the Turbo Tent, for example, with its integral frame structure and spring-loaded joints, goes up in a flat minute. But you still need to add the fly and stakes. The Oz Tent is hyped for its rapid pitch, but it still requires stakes and guylines too. I got the pitching time for a Springbar down to a leisurely 15 minutes solo, or 10 with help.

Roof tents are universally marketed for their simple and rapid pitch, and for some models this is so. Hard-shell clam-shell models (hinged at the front), for example, are absurdly easy to deploy: You simply undo the latch(es) and hydraulic struts raise the roof. Done in five seconds. Some hard-shell box-style tents have the same system. Closing is just as simple and quick.

Soft-shell roof tents, however, vary widely in ease of deploying and, especially, stowing. The transit cover can be easy or difficult to remove before deploying the hinged floor and watching the canopy bloom. Window awnings need spring struts installed from inside, and if you’ve added a changing room you essentially have a ground tent to deal with as well, which must be attached to the frame of the tent at the top and staked out at the bottom. But it’s the process of stowing a soft-shell tent—and especially re-installing the transit cover—that can be the most time-consuming. I’ve done a lot of cursing while trying the stretch Velcroed covers back over several models I’ve reviewed. Nevertheless, on balance a ground tent will most likely take more time to pitch and stow than a roof tent.

A Technitop soft-shell roof tent with annex (or “mullet”)

Wind and precipitation resistance. This is more a function of the individual model rather than the type. A roof tent, of course, has the advantage of being bolted to a two or three-ton ground anchor, so there’s scant chance of it blowing away. And hard-shell roof tents, both the clam-shell and box style, tend to be superbly wind resistant. Soft-shell roof tents, on the other hand, can be okay or really bad. I’ve seen few that have adequately strong supports for the window and door awnings, and in general rain flies tend to be very poorly secured and prone to maddening flapping. Whether or not the tent itself is wind-resistant, it’s perched atop a vehicle with suspension and acts as an effective sail, so boat-like rocking can be a factor in getting a peaceful night’s sleep.

Any ground tent must be staked to be secure, and if possible I stake out guylines as well—I’ve never experienced a tent that was too wind-resistant. Staking can be problematic if not virtually impossible in several substrates: sand, mud, or slickrock, for example. The Springbar is the only big ground tent I’ve ever tried that comes with adequate stakes. Buy big ones; you won’t be sorry.

I’ve slept in roof tents that leaked and in ground tents that leaked, so again this is more a function of quality control than one style or the other.

You can’t beat the space in a ground tent

Sleeping comfort and bedding storage. Unless you suffer from claustrophobia, as my wife does (she once nearly knifed her way out of a smallish clam-shell tent after a midnight attack), actual comfort could be considered a tossup. Most roof tents come with thick, comfortable mattresses, on which you can use sleeping bags or standard bedding and pillows—which in many models can also be stored inside. Ventilation is generally excellent, and you’re up where breezes are unhindered and more free from dust than at ground level.

For any ground tent you must separately arrange (and store) cots or mattresses plus sleeping bags. With that said, a good cot topped with a thick Thermarest and a flannel-lined sleeping bag provides one of the most transcendent sleeps on the planet—right up there with being partway to the sky in a roof tent, like a kid in a tree fort. Take your pick. (One P.S.: With cots as your beds, it’s much easier to sleep outside on clear nights than it is to extract the mattress from a roof tent.)

Fuel economy/cargo space. Even the sleekest hard-shell roof tent will add significant aerodynamic drag, and with one of the big soft-shell designs on your rack you might as well be towing a drogue parachute. Clearly a ground tent stored inside the vehicle presents no such issues—but then a big ground tent might take up so much space you’ll be tempted to strap other gear to a roof rack. Win to the ground tent as long as you can avoid a roof load.

Other trade-offs. A roof tent is nice if the substrate is muddy, when a ground tent would wind up slimy outside and possibly in. Climb the ladder to the roof tent, remove your muddy shoes and store them in the pocket provided for just that purpose on many models, and your little home stays spic and span. On the other hand (you knew there’d be one), if the ground is muddy it means it’s been raining and is likely to rain more, and we’ve already discussed how much nicer it is to be holed up in a spacious ground tent. Take your pick.

In some situations, a ground tent can be left in place to reserve your campsite while you go exploring in the vehicle. A roof tent obviously needs to be put away completely to do so.

Rather counterintuitively, leveling the tent is easier when it’s attached to the vehicle, as you can use blocks or even rocks under the tires. A ground tent needs actual level ground. Also it’s usually easier to reorient a vehicle and roof tent than it is a staked and guyed ground tent, to account for shifting breezes.

A ground tent is way easier to move between vehicles, or to loan out to a friend.

Much has been made of the safety factor of a roof tent in regions with large mammalian predators, especially Africa. Honestly, after quite a few nights spent in both roof and ground tents on the continent, I find this a weak argument. Predators very, very rarely mess with tents, much less try to gain entrance. Yes, I’ve seen the YouTube video of the lions pawing at the ground tent, but I’ve also seen the one of the elephant disassembling the roof tent. Either is an extremely unlikely situation. And if you’re worried about creepy crawly things like snakes sliding into your ground tent and cozying up to you in the middle of the night, keep the door zipped shut.

So there you have it, and I’m sure there are other arguments for each. If you’re already a fan of one or the other you’ll find it easy to count up enough arguments in your favor. Otherwise, perhaps this list will help tip you one way or the other, depending on your own priorities.

Part Souq, an international resource for parts

Whenever possible I try to buy parts for our vehicles locally. For the newer ones this is generally no problem, but automobile dealers seem to be increasingly reluctant to stock parts for any model more than a few years old. And when you begin your conversation with the counter person with, “I have a 1973 . . .” he looks at you like you just stepped out of a time machine. (It would be fun to run with this some time, and as he’s looking futilely at his screen for spark plugs to fit a 46-year-old FJ40, say something like, “So, do you think Nixon will resign?”)

If parts for the 40 flummox the dealer, imagine the situation with a 1993 HZJ75 Troopy that was never even officially imported into the U.S. I don’t even try.

Fortunately there are several specialty Land Cruiser shops around the country that carry at least the commonly needed items for 70-Series Land Cruisers, and a few have surprisingly extensive inventories. In part this is due to the happy fact of a model that has changed very little over its 35-year history. Cruiser Outfitters and cruiserparts.net are good sources.

However, even these enthusiast outlets can’t carry everything. And supposing you’re looking for something really arcane—like say, a Toyota factory floor mat in “sable,” the brown that is our interior color?

Some time ago I was introduced to an online parts source called PartSouq.com—“souq” being the Arab term for a market. (Amazon, I understand, recently bought the English/Arabic-language E-commerce site souq.com; I have no idea if the two are related.) I called up the site, clicked on the Toyota section (the site lists 20 brands and claims 17 million parts in its database). A prompt asked me for the VIN of the Troopy, so I retrieved that, typed it in, hit enter—and was rewarded with a complete catalog of parts for a 1993 Toyota Land Cruiser HZJ75. Engine, transmission, chassis, electrical, body—it was all there, with diagrams. I went to the interior section, hovered over the floor mat part number, 58510B (when you do this, the list on the side scrolls automatically to the correct placement), and clicked on that. It showed four factory floor mats available, three in gray, one in sable. The sable mat was located in . . . Oman? Yep. “Ships in one day,” it said.

Needless to say, clicking “Buy now” on a $310 item located halfway around the world took a leap of faith. Only the rave reviews I’d read of the site gave me the courage to do so. Shipping was nearly a hundred dollars—hardly unexpected.

What was unexpected was finding the large box containing our new Toyota factory HZJ75 floor mat, in sable, at our commercial mail service four days later. The mat was perfect, and a welcome replacement for the sadly (and hazardously) chewed-up original.

So if you can buy your parts locally, please do so to support your nearby economy. But if you can’t find it close, and the factory made it, there’s a really good chance it will show up on a PartSouq.com search.

The $50 MV50 air compressor. Yay or nay?

The ubiquitous MV50 air compressor, which is sold under a dozen different brands as near as I can tell, is not one I usually recommend. When they work, they work okay—not nearly as well as a truly high-quality compressor from Viair or ARB or Extreme Outback, but okay. Certainly the MV50 is a far better choice than those $29 plastic-bodied units with built-in flashlights that plug into the cigarette lighter. The MV50 has a metal body, and connects directly to the vehicle’s battery, which allows it to draw half-way decent amperage and thus put out halfway decent volume.

The problem with the MV 50s with which I’ve had experience has been consistency. Some owners have brilliant luck with them and wouldn’t use anything else; others have had them fail weeks into ownership. Yet so popular are they that you can easily find articles on hacking the unit for better reliability.

Recently I’ve been alerted to the MV50—in this case sold as a Masterflow Tsunami MF-1050—selling for under $50 on the Pep Boys eBay store (here at publication), with free shipping. At that price it’s a tempting bargain, even given the random instances of early failure.

I still urge those who ask me to spend til it hurts on their compressor, and I’ve never once had anyone come back and say he was sorry he bought an ARB Twin or an Extreme Outback ExtremeAir or even a Viair 400P. But if you really, really can’t afford that kind of money, at $50 the MV50 is a decent proposition—and way, way better than no compressor at all.

An odd winch bumper

I’m always on the lookout for inspiring—or horrifying—modifications and accessories on the four-wheel-drive vehicles I spot anywhere in the world. But this curious example was right here in Tucson.

I’ve written many times about the critical need to have visual and tactile access to the winch drum, and if this Jeep actually had a winch mounted to the bumper the operator would certainly have that access. But the plate securing the roller fairlead stumps me. For the life of me I cannot figure out the point of having it angled the way it is. The best wild guess I could come up with is that it vaguely mimics the look of the “stingers” so popular in a certain segment of the 4x4 community; however, it certainly wouldn’t function as one, and looks to me like it would hamper the function of the fairlead.

With no winch mounted it’s difficult to be certain, but it appears the winch line would skim the bottom of the cutout for the fairlead very closely indeed when the drum was full. Since the side rollers are angled, a side pull would result in the line partially dragging on the roller, reducing its effectiveness—a minor flaw to be sure, since given a hawse fairlead the line drags all the time. However, on a steep uphill pull (a common winching scenario) with a side pull factor thrown in, the line would be at a very steep angle near the top of the side roller.

Finally, on a general note: While I’m no welding expert, the bead along the winch plate and fairlead plate is really sloppy, and looks as though it might be lacking adequate penetration as well.

An odd winch bumper, to be sure.

Hint: When using “Search,” if nothing comes up, reload the page, this usually works. Also, our “Comment” button is on strike thanks to Squarespace, which is proving to be difficult to use! Please email me with comments!

Overland Tech & Travel brings you in-depth overland equipment tests, reviews, news, travel tips, & stories from the best overlanding experts on the planet. Follow or subscribe (below) to keep up to date.

Have a question for Jonathan? Send him an email [click here].

SUBSCRIBE

CLICK HERE to subscribe to Jonathan’s email list; we send once or twice a month, usually Sunday morning for your weekend reading pleasure.

Overland Tech and Travel is curated by Jonathan Hanson, co-founder and former co-owner of the Overland Expo. Jonathan segued from a misspent youth almost directly into a misspent adulthood, cleverly sidestepping any chance of a normal career track or a secure retirement by becoming a freelance writer, working for Outside, National Geographic Adventure, and nearly two dozen other publications. He co-founded Overland Journal in 2007 and was its executive editor until 2011, when he left and sold his shares in the company. His travels encompass explorations on land and sea on six continents, by foot, bicycle, sea kayak, motorcycle, and four-wheel-drive vehicle. He has published a dozen books, several with his wife, Roseann Hanson, gaining several obscure non-cash awards along the way, and is the co-author of the fourth edition of Tom Sheppard's overlanding bible, the Vehicle-dependent Expedition Guide.