Overland Tech and Travel

Advice from the world's

most experienced overlanders

tests, reviews, opinion, and more

Swarovski NL Pure binoculars . . . a new paradigm?

One of my favorite binocular interactions took place when Roseann and I were caretakers in Brown Canyon, in the Baboquivari Mountains about 50 miles southwest of Tucson.

Among our duties was leading hiking and birding tours along the canyon’s sycamore-lined creek.

After we’d taken one group up to a natural arch on a morning walk, we all gathered on the big shaded porch of the caretakers’ house to have lunch and look at birds on our feeders and in the trees. At the time I was using Leica BN 10 x 42s, one of the best two or three of its type in the world, and one of the guests was an amiable but crusty older fellow who had spent much of the hike teasing me about the fact that his binoculars cost less than a fifth of what mine had.

Now he came and stood by me while we both leaned on the porch rail and scanned the trees, and started right in again.

“I’m sure they’re great and all, but mine do just fine. I just don’t see how those can be worth the money.” I had mostly smiled and shrugged up to this point, biding my time.

Soon, though, he spotted something and said, “Kestrel in the big dead tree on the other side of the creek. Can’t tell if it’s male or female. (Male kestrels are most easily identified by their blue-gray shoulders.)

I looked through the Leicas and said, “Male.”

He eyed me dubiously. So I took off the Leicas and held them out.

He accepted them with an exaggerated show of care and looped the strap around his neck. He looked through them toward the tree, adjusted the bridge to fit his face, looked again. He pulled them down and looked at me, then looked through them again. He did a slow sweep of the canyon, looked up at the top of the ridge, looked down at the blue-throated hummingbird at one of the feeders. Finally he pulled them off and held them out to me, and with a deep, shuddering, what-have-you-done-to-me sigh, said, “Okay. I can see how they’re worth the money.”

Let’s be honest: Not everyone needs a binocular that costs as much as a decent used car. (Side note here: I bounce back and forth randomly between referring correctly to the instrument in question as “a binocular,” and referring to it in the vernacular as “a pair of binoculars,” which of course it really isn’t.)

As a natural-history writer, guide, birder, and hunter I’ve always felt justified in spending whatever it took to carry the best optics, just as an auto mechanic might justify Snap-on tools, or a graphics designer an 18-core iMac Pro. But let’s continue the honesty: Many people, including me, unapologetically derive great satisfaction and joy from using the best of whatever equipment they employ, whether or not it might be a deductible expense. I can justify high-end optics, but in the end I simply enjoy them, and never tire of the sharp intake of breath I experience every time I magically bring a bird or a whale or a distant landmark or a Ferrari on a race track ten times closer.

The stratospheric upper echelon of binocular performance is a battleground in which three manufacturers, and sometimes a fourth, fight for dominance with instruments that are in every sense pinnacle products. These manufacturers—Leica, Swarovski, Zeiss, and occasionally Nikon when the company is feeling feisty—spare no expense to make their flagship product as perfect as it can possibly be, and damn the cost. The best glass, coatings, and prism designs to produce the brightest, sharpest image; the strongest and lightest materials to gain supreme durability, weatherproofness, and comfortable long-session viewing; and the latest technology to stay abreast or incrementally ahead of the current competition’s best.

Thanks to that, “Hey, I’m a pro, I need the best” justification, plus the opportunity to review binoculars a couple dozen times over the years, plus just general binocular geekness (I own . . . several . . . including a Zeiss 10 x 40 BGAT from West Germany, arguably the very first ultra-premium binocular), I feel competent to judge differences in high-end binoculars sometimes measured in a percentage point of light-gathering ability, or a molecule-wide fringe of chromatic aberration, or a couple of feet of field of view, or an ergonomic detail unnoticeable unless you’d had the instrument to your eyes for a solid half hour. For at least the last decade it was only such minute variations that defined the differences among the big three and the notion of which one among a transcendent group was “best.”

Until last month, that is—when Swarovski introduced their entirely new NL Pure line of roof-prism binoculars, in 8 x 42, 10 x 42, and 12 x 42.

I have a connection to Swarovski that goes back to the 1980s, when I bought a pair of their Habicht 10 x 50 porro prism binoculars, magnificent and bulky beasts that I used while guiding sea kayak trips in Mexico, simply strapping them down on the deck of my boat where waves frequently washed over them. They performed flawlessly for a decade until I decided to move to a more compact roof-prism instrument, at which point I sold the Swarovskis for more than I had paid for them.

My current binocular is a Swarovski 10 x 42 EL, a brilliant instrument built in the double-bridge style the big three adopted for their top-end products a few years ago. To get a feel for how good these things are, go outside and look at a car or tree a hundred feet from you, then walk up until you are ten feet from it. That’s what the view is like through the ELs—the world is simply ten times closer. The only things less than perfect about the ELs (for me) is that the molded-in thumb grooves don’t quite match where I put my thumbs—obviously a personal-fit issue—and the fact that the big focus wheel sits slightly behind the neck strap lugs. I like to keep two fingers on the focus wheel because I’ve developed a technique of “walking” my index and middle finger rapidly across the wheel to go instantly from close to far focus, and on this binocular the strap lugs lightly dig into my hands when I do this.

When I pulled the new NL Pure 10 x 42s out of the box, it was apparent the ergonomics were going to be in a different league. The optical tubes of the single-bridge design (which I prefer, although strictly for aesthetics) were markedly constricted in the center, giving the binocular an elegant wasp-waisted look. More important, that constriction made the NLs the easiest full-size binoculars to hold I’ve ever used, even one-handed.

It’s easy to get a full wrap on the narrow barrel

I’m told the engineers accomplished this through the why-didn’t-someone-think-of-this-before strategy of rotating the binocular’s Schmidt-Pecan roof prisms, but I haven’t yet seen an internal view of the optics so I don’t know if any other tricks were employed. In any case, when I tried the NLs I was immediately convinced they were lighter than the ELs—not so, they’re actually a few grams heavier but don’t feel it.

One-handed use is easy with the NL Pure

The focus wheel was another pleasant surprise—it’s now in front of the strap lugs and falls perfectly to hand, or finger as it were. I can finger-walk the Pures from their excellent close focus of just 6.6 feet out to infinity in a couple of seconds.

Focus wheel is perfectly positioned

But ergonomics were almost secondary to the real news. The NL Pure introductory video promised a new high water mark in the field of view for full-size binoculars, and that was an understatement. In the past one brand or another would boast of a field of view three or four feet wider than its competitors at 1,000 yards. I’d have to look through one, rolling my eyes back and forth, then through the other, doing the same, before finally concluding, yep, a bit of difference.

Optics transmit 91 percent of available light. The black inserts can be swapped out for hinged objective-lens covers for those who prefer them.

Not the Pures. I looked through my Leica 10 x 42 Ultravids, then through the NL Pures, and wham. The difference was stunning: 336 feet to a horizon-spanning 399. I looked through my own Swarovski 10 x 42 ELs—until now the company’s top of the line product—and then the NL Pures, and wham. Same difference. The field of view of the 10 x 42 Pures is the wide as the company’s 8.5 x 42 ELs. The only binocular I’m aware of that comes close to the field-of-view performance of the NL Pure is the Zeiss Victory 10 x 42, at 394 feet.

The challenge with providing such a wide field of view is maintaining sharpness all the way out to the edges of the field. The wider the field, the harder that is to do, and the greater likelihood of distortion and chromatic aberration as well. As near as I could tell, the Pures maintain sharpness and color to the edge of their 399-foot vew as well as the ELs do to their 336-foot view—that is, superbly.

Diopter adjustment is on a toggle behind the focus knob

So far, so spectacular. But along with the NL Pures the company sent a new (extra-cost) option: the FRP, (for Forehead Rest Pure, I think). And I have to be honest, when I saw this device for the first time I laughed out loud. It reminded me instantly of the Optigrab, Steve Martin’s ill-fated eyeglass accessory from The Jerk.

Not a gimmick. Really.

The forehead rest is exactly what it says—a small, adjustable pad that plugs into the bridge of the binocular after removing two screws. A dial moves it in and out to achieve gentle but solid pressure on your forehead to help stabilize the view—a problem for some people using 10-power binoculars, and probably a problem for most people using the NL 12-power instrument.

So, in the interest of due diligence, I removed the two little screws, plugged in the Optigr . . . I mean forehead rest, and went outside to try it.

And. Well. Dammit . . . the thing actually works. I’m very steady with 10-power binoculars, but using them with and without the rest I could beyond any doubt feel the difference—and trust me, I didn’t want to feel a difference. I instantly knew of a situation where this device would be a huge advantage for me: When I hunt deer or elk I normally do what is called, illogically, still hunting, which involves moving slowly through habitat and stopping frequently to glass. I always do this one-handed, keeping my other hand on the rifle. And the Pure forehead rest dramatically increased stability when I held the binoculars one-handed. (I often do this when hiking and looking for birds, too, come to think of it. And Roseann does it all the time while sketching.) Suffice to say the FRP works as advertised.

Even the NL Pure soft case is innovative. It opens sideways like a clamshell and the binocular lays in on its side. It’s far easier to access and store them than in the traditional vertical case. Well done Swarovski for rethinking something so mundane.

Quibbles? Okay: The strap incorporates a clever way to adjust its length instantly, but it leaves tails of strap flopping around. Since these weren’t mine I did not try simply cutting them off shorter . . .

Ergonomics, clarity, field of view. For the first time in years, I found a new premium binocular model to be a big leap from its predecessor, and a leap ahead of its competition. If you can justify the expense, you’ll find The Swarovski NL Pure worth every penny. If you can’t justify it, maybe consider a career change?

Swarovski is here.

Warn's "new" M8274 winch

When a product stays in production for a half century with virtually no change to its configuration or specification, you know the original designers were inspired with genius.

Such is the case with Warn’s M8274 winch. Introduced in 1974 as a mere tweak or two upgrade from the even more venerable Belleview winch (from 1959), the 8274 combined excellent power (8,000 pounds) with massive cable capacity (150 feet), and spur drive gearing that was not only superior in strength but more efficient than any other winch driveline on the market—75 percent, compared to 40 percent in the only other winch that can claim equally legendary status, the worm-drive Superwinch Husky.

The 8274 could also claim the fastest loaded and unloaded line speed of any production winch—an “advantage” that to my mind was not all that advantageous, since generally when I’m winching I want the process to proceed as steadily and slowly as possible. But some people like the speed, and in competition 8274s were commonly hotted up with second motors to increase speed still more.

Another advantage to the 8274 became apparent with the advent of synthetic winch line. The brake on the winch is external to the drum, which meant there was no chance of overheating the line when winching in reverse.

The 8274’s only practical disadvantage was its height and foot-forward mounting system, which required a dedicated bumper and a vehicle with clearance for the height. On my FJ40 it was a match made in heaven.

Thus from 1974 through 2019, the 8274 remained virtually unchanged. Now, however, Warn has announced a “completely new” version.

The “new” 8274 now boasts a 10,000-pound capacity thanks to a six-horsepower motor (although they have retained the 8 in the model designation, which referred to the original’s capacity). It can also be had from the factory with synthetic line. Importantly, the original solenoid-based switching mechanism for the motor has been replaced with a waterproof, solid-state Albright contactor. The solenoids, while durable, were not waterproof, and could on extremely rare occasions freeze in the closed position, which meant the winch would keep pulling even if the operator let go of the remote button.

So, why did I state “through 2019” rather than 2020, and why did I put “new” in quotes?

Because we have already seen this winch. It was introduced last year as the 70th Anniversary model (see here), with the same 10,000-pound capacity, Albright contactor, and synthetic line. What Warn has (apparently) done is to simply make the anniversary model the new standard 8274. Even the list price, an eye-watering $3,199, is the same.

Notwithstanding that tiny bit of marketing legerdemain, the new Warn 8274 looks set to enjoy another several decades as the winch against which all others are measured. If you have a serious expedition vehicle with an appropriate mount, there is no better choice.

Warn is here.

A better Hi-Lift handle keeper?

If you own a Hi-Lift jack, you’ve probably dealt or struggled with the issue of how to lock the handle firmly in place during transport.

The spring clip that comes on the jack is worthless (and not designed) for that purpose. The polyurethane collars that slip over the handle and shaft are okay, but in my experience they stick when new, and eventually wear and slip down on the jack if it’s stored upright, or vibrate right off the end if it’s stored horizontally. For a time I just used a piece of One-wrap (hook-and-loop tape), but I’m not a big Velcro fan, and it quickly clogs with dirt when used in such an application.

A few years ago I set out to make something better. With an old sheet of half-inch-thick HDPE plastic—I don’t even remember what from, perhaps a cutting board?—I started playing around with ideas, and eventually came up with what you see here.

It slips easily over the shaft and handle of a Hi-Lift, and you can lock it anywhere you like with the two through-pieces and then the spring clip. It can’t slip. The only disadvantages I’ve found are that it won’t slide over the removable clamping foot if you keep one attached (although you could modify the opening so it could), and it has multiple pieces that might be prone to loss. However, I think it would be easy to modify it with a safety wire that would keep all three plastic bits together.

Always remember to store your Hi-Lift with the operating lever in the “lift” position.

P.S. If you don’t want to make your own, Step22 Gear has a promising alternative, here. I just got one and will be reviewing it soon.

Anti-Gravity Batteries' Battery Tracker

I’m not much of a mobile phone person—in fact I hate the things and would happily revert to a black Bakelite dial phone in a little nook in the hallway. But such is no longer the way of the world.

One bright spot of the new world is the availability of apps, which tend to be far more useful than the average actual phone call. I have the Star Walk astronomy guide—which is pure magic—and a bird guide that not only has descriptions and photos but will play the bird’s song for you. Brilliant. Motion-X GPS of course, and several practical tools such as inclinometers and an OBDII reader.

But way too many apps seem to exist just because they can. I recently got an otherwise excellent LED flashlight to review, the programming of which is accomplished with an app. Seriously? I need to clutter my phone with another program just to tell my flashlight whether to come on bright or dim when I push the button? Absurd.

Thus—even though I’ve been a fan of Anti-Gravity Batteries and their superb Micro-Start since the beginning—I wasn’t sure about their Battery Tracker, which is also paired with an app. Nevertheless I decided to give it a try.

The Battery Tracker is designed to let you monitor battery status via a smart phone. Okay, let’s see how it works.

Well, it works about as simply as one could imagine. Use your smart phone to scan the squiggly square thing on the package. (Roseann chimes in: “Uh, that’s called a QR Code, Mr. Gates.”). And bink, there’s the (free) app. Hook the wires on the tracker to the positive and negative terminals of the battery, and you’re done. The phone pops up with the voltage. I was disappointed the tracker didn’t come with a penny’s worth of double-sided tape to adhere it to the battery, but we had some.

Okay, battery voltage. Wirelessly. I can check it from the living room. I still wasn’t really getting it, so I kept reading the instructions. Aha: you can set the tracker to send you an alert if your battery’s voltage drops into the danger zone. That’s cool. It will also run a cranking test and a charging test to confirm adequate starting power in the battery and adequate charge from the alternator. Definitely a smart thing to do before a major trip.

And yet. I still wasn’t quite fully sold on it for my own use.

Finally I realized the problem. There was nothing wrong with the product; I was just using it on the wrong battery. I swapped it from the starting battery to the auxiliary.

Suddenly it was brilliant.

Our auxiliary batteries are the ones that are working all the time, to run fridges, lights, chargers, and inverters. Some of us install voltmeters in the system to monitor them, but you need to get up from the Kermit chair and go look at it, leaving your campmates ample time to steal your drink and gorge on the snacks. Others of us simply guess how long we can go without charging until the low-voltage cutout on the fridge kicks in. Now a simple glance at the phone will tell you if it’s time to re-orient the solar panels or go for a drive. And the tracker can alert you before the beer gets warm.

But that’s not all. The tracker can give you a 31-day record of charge condition. This would be perfect when setting up an auxiliary battery system, especially with solar input. You can determine if the all-important float voltage is being reached every day—critical to long battery life.

At $36 the Battery Tracker is reasonably priced, and could be used to significantly extend the life of your auxiliary (or main) battery, saving its cost several times over.

Anti-Gravity Batteries is here.

Why you need the new edition of Tom Sheppard's Four-by-four Driving

If you want to be a better driver— and who doesn’t no matter what level we might consider ourselves to be at the moment?—and you don’t have this book, you need it. Trust me on this.

Full disclosure: I receive a bit of commission on every copy sold in the U.S., and I contributed the sections on winching and Hi-Lift/ARB jacks. But that’s not why I want you to buy it.

The reason you need it is because there is no other instructional book on four-wheel-drive technique that does what Tom Sheppard does in this one.

Four-by-four Driving doesn’t simply tell you how to drive in different situations. As the blurb on the back cover states, “I.T.D.S.—It’s the Driveline, Stupid.”

Knowing how to drive is great. Knowing why the vehicle does what it does, knowing how different drivetrains operate and how each reacts to differing terrain, knowing the strengths and weaknesses of each type of four-wheel-drive system, and learning how to exploit those strengths and accommodate those weaknesses, will turn you from a competent driver into a master of the machine and the terrain. I still learn or am reminded of those lessons every time I open my copy.

You can, if you like, just read the section in Four-by-four Driving that covers your own vehicle, but you’ll gain much more if you read through the descriptions of drivetrains and operating systems of vehicles around the world. Not only can you master your Tacoma, you’ll be able to hop in a friend’s Discovery or Wrangler or G-Wagen and master it too. In fact if you dedicate yourself to the first part of this book you could probably be air-dropped anywhere on the planet and stand a good chance of knowing how the dominant local transport works. Suzuki Jimny? Sure. Skoda Karoq Scout? Yep. On the off chance you find yourself in a Rolls Royce Cullinan, you’ll be right at home. And this edition includes, among other updates, full technical details of the new Land Rover Defender. (If you already own the fifth edition, note that the Defender coverage comprises the majority of changes to the sixth.)

Only after explaining drivetrains, traction-control systems, suspensions, and operating systems does the book start in on driving techniques, beginning with what I consider to be the basic skill that must underpin all others: mechanical sympathy.

Then, yes: You’ll learn how to drive on sand, mud, ice, and rocks. You’ll learn how to handle ruts, side slopes, water crossings, hill ascents and descents. Following this comes a chapter on recovery, both solo and assisted (and that brilliant section on winching . . . ).

Finished? Not even close. Now comes a section on advanced driving. If you ever find yourself plopped in the driver’s seat of a 60-year-old Bedford truck with a non-synchro gearbox, you’ll learn how to handle it. Or, want to show off by shifting the transfer case in an FJ40 or Series Land Rover from low to high range, while moving? That’s in there too.

Following all this are sections on expedition basics, tires and tire pressures, loading and lashing, oil types and grades, fuel, water . . .

But it’s in Four-by-four Driving’s former-RAF-test-pilot level of detail explaining how four-wheel-drive vehicles do what they do that the real gold of the book lies. Which explains why, unlike those 30 different watches you can buy that all claim to be “Used by Special Forces,” Four-by-four Driving actually is used as a training manual by special forces in both the U.K. and the U.S. It’s worth every penny.

Available right here.

Not so simple: The simple redirected winch pull

Take any reasonably comprehensive winching course and, once you’ve covered the basic single-line pull, you’ll be introduced to the snatch block—or, more recently, its elegant one-piece alternative, the billet-aluminum recovery ring.

A pulley—which is what both devices are—serves a couple of purposes in a winch system. Most impressively, when a winch line from a vehicle is led through a pulley attached to an anchor and then back to a recovery point on the vehicle, the power of the winch is essentially doubled (minus minor frictional losses) while line speed is halved. (A corollary to this is that by pulling more line off the winch to rig a double-line pull, you are further increasing the power of the winch by reducing the layers of line on the drum. Thus you receive a double benefit during a difficult recovery.)

The other valuable use of a pulley is to redirect a pull—around a corner as it were—when a straight one is either awkward, dangerous, or impossible. It’s frequently used to recover a bogged vehicle when a recovery vehicle equipped with a winch cannot be positioned directly in front of it. A suitable anchor such as a tree is employed as a redirect point, using a tree strap and a pulley.

When you learn how to rig a redirected pull you’ll also learn that this use of a pulley does not multiply the power of the winch, nor does it halve the line speed. The easiest way to figure out whether or not you are multiplying winch power in any situation is to count how many lines are shortening when you engage the winch. For example, in the illustration below labelled Double-line Pull, both the line from the winch to the pulley and the line from the pulley back to the vehicle will shorten as the winch pulls, thus the power is multiplied by two.

On the other hand, in our simple redirected-pull scenario above, only the line running from the pulley to the bogged vehicle will shorten—the distance between the pulley and the winching vehicle will not change. Therefore the winch is operating at its rated power.

But now comes the not-so-simple part. What about the load on the anchor?

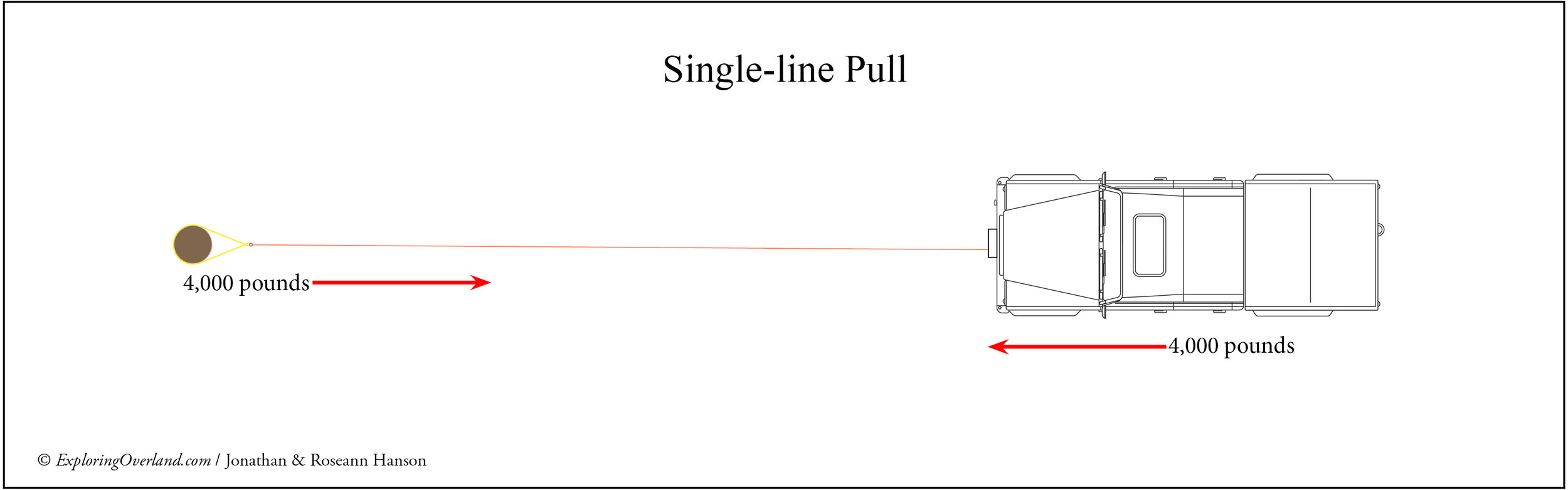

Let’s assume that in all our scenarios, the bogged vehicle needs 4,000 pounds of pull to retrieve it. If the operator rigs a single line pull to the tree anchor directly in front of the vehicle and engages the winch, the load on both the winch and the tree is 4,000 pounds.

If the operator rigs a double-line pull, the vehicle still needs only 4,000 pounds of pull to move. Due to the effects of the pulley the load on each line is halved, to 2,000 pounds; thus the winch is only exerting 2,000 pounds (and only drawing the amperage necessary for that), and the recovery point on the vehicle is also experiencing 2,000 pounds of force. The load on the anchor remains 4,000 pounds.

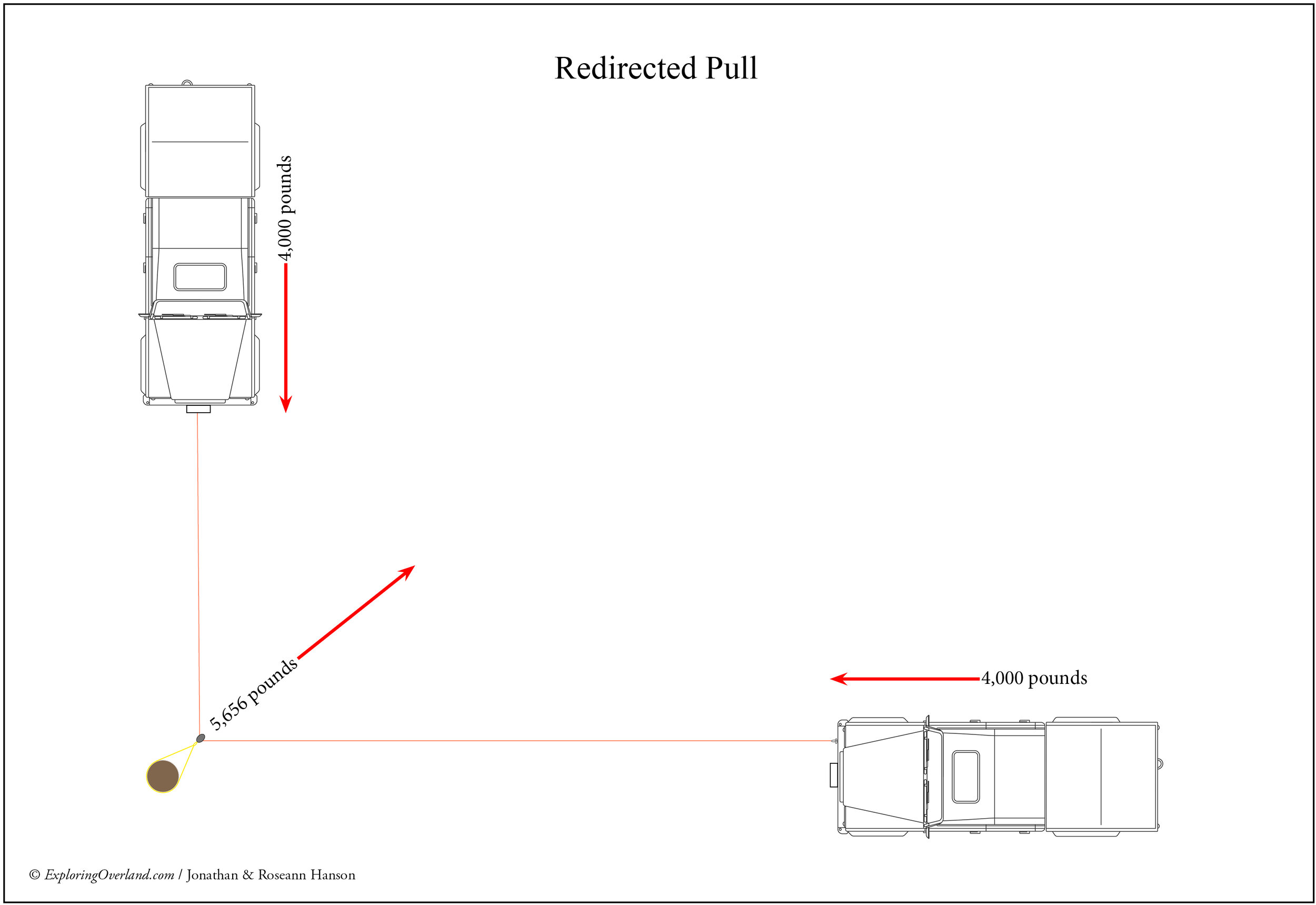

So far so good. Now let’s take another look at our redirected pull, where one vehicle is at 90 degrees to the other. In this scenario, the bogged vehicle still needs 4,000 pounds of force to move. The winch on the recovery vehicle is also subjected to 4,000 pounds—again taking into account slight frictional losses. So the force on the anchor must also be 4,000 pounds, right?

Actually . . . no.

In this case—a 90-degree redirected pull—the force on the anchor will actually be 5,656 pounds, almost 50 percent higher. The force is calculated using the formula:

pull = 2t(cosine x)

. . . where pull is the force on the anchor, t is the force exerted by the winch, and x is one half the angle at which the winch line passes through the pulley (in other words, the direction in which the anchor would move if it failed; in a 90-degree redirect it would be 45 degrees).

So, in our case, 2 x 4,000 pounds is 8,000, multiplied by the cosine of 45º which is .707, equals 5,656 pounds.

There’s more. As the angle between the bogged vehicle and the recovery vehicle narrows, the force on the anchor continues to increase. Imagine the scenario below, in which the recovery vehicle has to be situated directly alongside the bogged one—I’ve been in this situation. In this case, with the angle between the winch lines near zero, the force on the anchor would be (very nearly) doubled, to 8,000 pounds—even though the bogged vehicle is still only subject to 4,000 pounds of pull to free it. Imagine a tougher scenario in which the recovered vehicle took the full might of, say, a 10,000-pound winch to free it. In such a case that pine tree you wrapped your strap around is going to have about 20,000 pounds of force trying to pull it over—and all the hardware attached to it will be subject to the same stress.

You don’t actually have to have a calculator with a cosine function to figure the increase in force if you use a chart such as this, where “factor” equals how much the force on an anchor is multiplied by different angles of redirected pull :

And, in reality, you don’t need to do any figuring or checking at all. All you need to remember is that in any redirected pull, the force on the anchor can be up to twice what the rest of the system is subjected to. And the anchor includes the tree or chocked vehicle or whatever you are rigging to, as well as the tree strap, shackle, and pulley in the anchor assembly.

Non-instinctive effects of physics such as this reinforce the axiom always to use recovery equipment rated for the vehicle and winch, with working load limits (WLL) clearly marked, and adequate safety factors.

Learn how to winch online! Or not.

The greatest thing about the Worldwide Web is the vast amount of information accessible with a few clicks of a computer mouse.

The worst thing about the Worldwide Web is the vast amount of mis-information accessible with a few clicks of a computer mouse.

As part of my explorations of the online overlanding world, I occasionally browse through instructional YouTube videos, and I am frequently reminded how many of them should be called “instructional” videos. Sometimes the information in the latter type is harmless. Other times it is decidedly not harmless. That especially applies when the “instruction” is about winching.

Consider the video I have bookmarked in which the host attempts to demonstrate the party trick of moving a vehicle backward with a front-mounted winch. In essence this is a simple and virtually worthless procedure that involves running the line from the winch through a snatch block anchored to a tree in front of the vehicle, then to another attached to a tree behind the vehicle, then back through a third snatch block mounted on the vehicle’s rear recovery point, and finally to an anchor. When the winch is engaged the mathematics of the line being pulled results in the vehicle moving slowly backward. Aside from the fact that very few of us carry three snatch blocks, the odds of anchors being in exactly the right spot to rig this system where you might get bogged are scant. Our host got around the problem of multiple snatch blocks by simply using shackles instead—with steel winch cable. Ouch. He also utilized a child’s car seat as a winch line damper. Needless to say his attempt failed. However, the furthest anyone really needed to go with this “instructional” video was a glance at the fellow’s “spooled” winch cable.

A rat’s nest just begging for a snarl or jam.

In another demonstration of reverse winching, a cheerful Aussie bloke uses a kinetic strap as a tree saver—pretty much the most egregious never-do-this move you can make when rigging a winch recovery.

However, a recent video I watched, from Bold Canyon Outdoors, was in a way even more confusing, as it boasted decent production values, a well-spoken host, and significantly better equipment. The video offered a basic guide to winching, including a single, double, and triple-line pull.

It started out with a bit of humor, which was fun. But after the host brought out the winch kit he was using—and heavily promoting—from a company called Gear America, and began discussing the procedure, things began to go south. If I went through the video again I could probably pick out more goofs, but what I noticed immediately included the following.

First, he simply introduced a Jeep Wrangler with a winch. He said nothing about winch selection, sizing, mounting—the winch was simply there, taken for granted.

Then, when he introduced the “Gear America Ultimate Winching and Rigging Off Road Recovery Kit” (yes, really), he made no mention of matching the kit to the winch, no mention of working load limits (WLL) or minimum breaking strength (MBS) of the shackles or snatch block. He pulled out a “tow strap” included in the kit. Was it truly a tow strap, or a kinetic-recovery strap? Big difference. You can use an elastic recovery strap to tow with, but it would be dangerous to use a non-elastic tow strap as a kinetic recovery strap. He referred to the bow shackles in the kit as D-rings—not a big deal, you might say, but the little mistakes and omissions were quickly adding up to a not-very-credible presentation.

When the host ran the winch line out to a tree to use as an anchor, he mentioned nothing about choosing an appropriate (i.e. live and large enough) tree to take the strain. He also, critically, failed to check overhead for dead limbs that could be dislodged by the stress of winching. He properly employed a tree saver strap, but positioned it above waist height. A tree strap should be positioned as low as possible to reduce stress on the tree. Finally, when he connected the winch line to the tree strap with a bow shackle, he specified that the shackle pin should be “snug”—an elementary beginner’s mistake. A shackle pin should be snugged, then backed off a quarter turn or so. This is not a safety issue, but a way to ensure the pin doesn’t jam under load.

He then properly advocated employing a winch line damper to help control a recoiling line if a component in the system breaks. He placed the weight in the middle of the line. This is a small point, but I prefer placing the damper closer to the end of the line where the shackle and winch hook are—those are the heavy bits that represent the most danger should either or both come loose.

Next the host demonstrated a double line pull. While doing so, he introduced the Gear America snatch block, and noted that it is “suitable for either synthetic or steel winch line.”

Ugh.

The Gear America snatch block has a steel pulley with what looks like a standard semi-circular groove for the line. That’s perfectly suited for steel cable. A snatch block for synthetic line should ideally have a composite pulley. More to the point, while the steel Gear America pulley could be used with synthetic line, you would certainly not want to do so once it had been used with steel cable, and you most definitely would not want to swap back and forth. Steel cable will leave micro-abrasions on the pulley that are not good for synthetic line. (For the same reason, a winch fairlead—whether hawse or roller—that has been used with steel cable should be replaced if synthetic line is installed on the winch.)

I looked up Gear America, which seems to specialize in low-cost recovery equipment. The “Gear America Ultimate Winching and Rigging Off Road Recovery Kit” actually comprises a pretty basic assortment of kit, including what the website lists as a “tow strap.” Hmm. So I looked up that product separately, and found its description: “Use it as a Tow Strap, Recovery Strap, Tree Saver Strap or Winch Extension Strap, making it an extremely versatile product.”

Oh brother.

I looked at the construction, which is polyester, meaning there will be very little stretch in this thing. Therefore the suggested use as a “recovery strap” is highly problematic, since a recovery strap is commonly made from nylon and designed to stretch and absorb shock when it is used in a kinetic recovery. A novice who had looked at just enough YouTube “instructional” videos to have a vague idea of how to snatch a stuck vehicle could easily break something or rip off a bumper by backing up and taking a run at moving a bogged vehicle with this “multi-purpose” strap. At least the site lists the MBS and WLL of the strap (35,000 and 12,000 lb).

Next I looked at the bow shackles included with the not-going-to-write-it-all-out-again recovery kit—which are actually described there as “D-ring shackles.” They’re 3/4-inch versions, a standard size in thousands of recovery kits, and properly stamped “WLL 4 3/4T,” or 9,500 pounds. With a standard six-to-one safety factor on shackles that works out to a 57,000-pound MBS. However, the description right under the photo of the shackle and its stamp says it has a “10,500-lb WLL and 58,000-lb MBS.” Hmm . . .

9,500 pounds? Or 10,500?

Not to worry about math. Below that is the assurance that you can:

MAKE A BOLD STATEMENT - Our Unique Design Ensures Unprecedented Strength and Looks Amazing on your Jeep or Tuck (sic).

Lastly I looked at the Gear America snatch block, and sure enough it’s listed as being suitable for both steel and synthetic line. Also, the snatch block itself is labeled “9 US ton,” while the description below it says it has a “10,000-pound working load limit,” and an MBS of 10 tons. So . . . which is it, guys? Further, it appears there is no WLL indicated on the product, which could lead a user to assume the “9 US ton” refers to a working load limit—a dangerous assumption.

My impression of the Gear America site, I’m afraid, is that is was conceived and created by some people who thought selling 4x4 recovery gear would be a good business, but who have very little experience with actual 4x4 recovery. Either that or they handed off their website design to someone with no clue, and didn’t do any fact-checking.

Going back to the Bold Canyon Outdoors video, I realized the host was simply parroting most of what the Gear America advertising stated regarding their products. But that’s no excuse: If you’re going to post an “instructional” video that involves a potentially hazardous activity (the one in question has had 8,000 views), you really should strive to get every detail correct.

Shackles: Are yours doing their job?

Proper shackle angle on an Old Man Emu suspension

I wonder if Obadiah Elliot had any clue, when in 1804 he patented a system of stacked steel plates designed to smooth the ride of a carriage, that his invention would still be in use two centuries later.

To be sure, the leaf spring has been eclipsed in sophistication by coil, torsion, and air springs, yet its simplicity, ruggedness, and low cost keep it standard equipment on the rear axles of millions of pickups and four-wheel-drive vehicles, as well as on the axles of larger freight-hauling trucks.

It’s not so much the cost of the spring itself that makes leaf-spring suspension systems cheaper to manufacture—it has to do more with the fact that a leaf spring also comprises its own locating mechanism. A coil or air-sprung beam axle requires a leading or trailing arm (or multiples) to secure it fore and aft, and a transverse arm such as a Panhard rod to locate it side to side. The leaf spring does both all on its own. Additionally, the stress a leaf spring applies to the chassis is divided between its front and rear mounting points, while the perch of a coil spring has to take all the load, requiring sufficient reinforcement.

Perhaps the biggest disadvantage of the leaf spring—that is, in the common configuration with multiple leaves—is inter-leaf friction, which not only hinders springing action but can vary or increase as, for example, the leaves become rusty. Some manufacturers such as Old Man Emu address this with a nylon pad at the end of each leaf, which can be lubricated.

There’s one situation, incidentally, when that interleaf friction can be an advantage—if you blow a shock absorber (as we recently did on our Land Cruiser Troopy), inter-leaf friction attenuates the endless cycling (bouncing) that would otherwise occur. If you’ve ever driven a coil-sprung vehicle with bad (or no) shocks, you’ll know what I mean.

Those of you with leaf springs at one or both ends of your vehicle likely have never given much thought to the shackles—those brackets that connect the free end of the spring to the chassis. But they perform a critical function, and their orientation can affect several aspects of suspension performance.

A leaf spring in its static position has a specified eye-to-eye length. When it flexes as the vehicle travels over a bump or through a hole, the spring “lengthens” or “shortens”—obviously it actually does neither; as it flexes the arch in the spring simply decreases or increases, changing the eye-to-eye distance. A leaf spring attached rigidly to the chassis at both ends could not flex at all, so the shackle travels through an arc to allow this. Clearly, then, you want the shackle oriented so it does this job as effectively as possible.

Take a look at this diagram.

Ignore for a moment everything but the angle at which the shackle meets the spring at the eye. This shows that angle as 90 degrees to the datum line—a line drawn straight between the eyes of the spring. For most practical purposes we can think of this as essentially right angles to the spring itself—an easy orientation to ascertain visually.

The most obvious and important result of this angle is that it lets the spring flex to its maximum extent both when compressed and extended. You can see that if the shackle were angled as in “A,” the spring could flex a lot downward (as the shackle pivots forward), but when compressed, the shackle would quickly bind against the chassis. Exactly the opposite is the case with the shackle at “B.” The spring has plenty of travel when compressed, but very little when extended. Another danger of a shackle angled as at “B” is that if the spring flexes too much the shackle can invert and lock itself against the chassis, completely immobilizing the spring.

You might also read or hear that the angle of the shackle can affect the ride quality of the spring—and this is where things get vague.

Note that this diagram claims that a shackle oriented at “A” will stiffen the ride while a shackle at “B” will soften it. I could find no explanation as to the physics of this supposed effect. On the other hand, I found a source claiming exactly the opposite. This one noted that with the shackle at “B,” when the spring compresses the shackle has to travel slightly downward in its arc before rising to the rear, and this jacks the chassis slightly upward, exacerbating the effect of a bump. Makes sense.

Not finished, however. Yet another fellow, with experience setting up racing vehicles, argues adamantly that the shackle has no effect either way on ride quality unless it actually binds. He points out that no matter what, the force from the spring is virtually straight up and down at the axle; the slight fore and aft movement imparted from the pivoting shackle is indiscernable. (He uses this fact also to argue against shackle-reversal kits as a waste of money.)

While the ride question remains unresolved, there’s no doubt that proper a 90-degree shackle angle allows the spring to do its job through the maximum possible travel in both compression and extension.

Look at the opening photo, which shows the rear of my FJ40 and its Old Man Emu suspension. The shackle angle is, as one would expect from the company, spot on (the front is as well).

In contrast, look at the shackle angle on the front springs of our Troopy:

Much closer to “B” in the diagram, no? These springs were installed at a shop in Perth, Australia, after we took it in to have them diagnose a worrying clicking noise I could both hear and feel through the steering wheel, and which neither Graham Jackson nor I were able to diagnose in the field except to be pretty sure it was in the steering. But the shop diagnosed worn springs, so we let them replace both sides.

We picked up the vehicle the day before we were scheduled to containerize both our and Graham and Connie’s Troopy for shipping to Africa—and as I drove away from the shop the clicking was there as loud as ever. Some testy and hasty negotiating resulted in a refund of all our labor charges, but the springs stayed on. (After getting the vehicle home I disassembled the steering and found indeed that was where the noise was coming from—just loose bolts in the tilt mechanism.)

Examining the springs in Durban I realized they had too much arch, resulting in this poor shackle angle. Whatever you believe regarding shackle angle and ride quality, these springs also definitely ride more harshly then the previous set, so I’m on a mission to fix both issues.

The first and most obvious approach is to remove a leaf in the springs. This isn’t necessarily as simple as it sounds, because removing the wrong leaf could create stress risers in the remaining leaves and lead to breakage. (So-called “add-a-leaf” kits can do this as well.) However, it looked to me that removing the bottom leaf on these springs wouldn’t compromise the rest of the pack, and the bottom leaf was the only one not captured with a clamp (or rebound clip to give it its proper name). So I jacked up the front end, loosened the U-bolts, and pulled the bottom leaves.

Notice the near-total lack of a wear pattern on the tips of the leaves.

After tightening everything again, I took the Troopy for a drive to settle everything then examined the results. Note the shackle angle in the first Troopy photo, and compare it to the “after” photo below.

If you’re thinking, “I don’t see the slightest difference,” congratulations. I don’t see one either. Clearly those bottom leaves are doing nothing at all—at least when the vehicle is static. They probably don’t provide any resistance until the spring is significantly compressed.

Since this is in no way an existential threat, I’m re-evaluating. I might still try removing another leaf, or I might just live with it for now—I certainly don’t intend to spring for new springs just yet . . .

Hint: When using “Search,” if nothing comes up, reload the page, this usually works. Also, our “Comment” button is on strike thanks to Squarespace, which is proving to be difficult to use! Please email me with comments!

Overland Tech & Travel brings you in-depth overland equipment tests, reviews, news, travel tips, & stories from the best overlanding experts on the planet. Follow or subscribe (below) to keep up to date.

Have a question for Jonathan? Send him an email [click here].

SUBSCRIBE

CLICK HERE to subscribe to Jonathan’s email list; we send once or twice a month, usually Sunday morning for your weekend reading pleasure.

Overland Tech and Travel is curated by Jonathan Hanson, co-founder and former co-owner of the Overland Expo. Jonathan segued from a misspent youth almost directly into a misspent adulthood, cleverly sidestepping any chance of a normal career track or a secure retirement by becoming a freelance writer, working for Outside, National Geographic Adventure, and nearly two dozen other publications. He co-founded Overland Journal in 2007 and was its executive editor until 2011, when he left and sold his shares in the company. His travels encompass explorations on land and sea on six continents, by foot, bicycle, sea kayak, motorcycle, and four-wheel-drive vehicle. He has published a dozen books, several with his wife, Roseann Hanson, gaining several obscure non-cash awards along the way, and is the co-author of the fourth edition of Tom Sheppard's overlanding bible, the Vehicle-dependent Expedition Guide.