Overland Tech and Travel

Advice from the world's

most experienced overlanders

tests, reviews, opinion, and more

Designing a Vehicle Build, Including a Virtual Troopy Tour – Free online workshop

Have you ever daydreamed about designing, and then actually building, your “dream vehicle” for overland adventure? In this free Overland Tech and Travel workshop, we walk you through how we started keeping field notes on their “perfect overland vehicle” in the 1990s, and then by 2016 began the process of buying, designing, and building our ultimate overlanding vehicle, a 1993 Land Cruiser Troop Carrier converted to a pop-top camper in Australia and eventually—after 29,000 kilometers and four years exploring Australia and southern Africa—imported home to Arizona.

RESOURCES FROM THE WORKSHOP:

Download PDF of build and specs. (left)

Download PDF of additional specs, resources. (this information also copied below)

Download vehicle weight / distribution report.

IMPORTATION – The U.S. allows virtually any vehicle over 25 years old to be imported without the need to conform to current standards. That means Troopies powered by the 1HZ engine—introduced in 1990—are now eligible.

AUStoUSA.com Darwin Troopy: $16,000 U.S. 1993, eligible for importation in 2018. [bought June 2016]. 244,800 km / 152,000 miles on odo.

Expedition Centre in Sydney. Daniel Fluckiger, Australian/Swiss owner

Mulgo aluminum pop-top conversion for the Troopy (and the Defender 110). Full standing headroom in the back, drop-down double bed with mattress; when closed raises the height of the vehicle only 30mm.

Arrived in Australia mid-July 2016 for a three-week crossing of the Simpson Desert.

FIRST ROUND OF ACCESSORIES FOR 2016 MADIGAN LINE / SIMPSON DESERT

Warn XD9000S winch in existing ARB bumper, spooled w/100 feet of 3/8-inch Dyneema.

ARB Intensity 21 round LED lamps

National Luna NL50 fridge/freezer combination

125-watt photovoltaic panel

Brackets for MaxTrax at front of roof

Second round of modifications (2017), Tasmania & RED DESERT CENTER TRIPS

Cabinetry per CAD drawings

95-liter stainless-steel water tank between chassis rails

ARB Twin air compressor

Kaymar rear bumper/carrier

Recaro Specialist M seats and SupaFit covers

Eezi-Awn Bat 270 awning, two side panels

Third round of modifications (2018) WESTERN AUSTRALIA DESERT CROSSING

Ultimate Suspension springs, twin-tube gas shocks, “Sumo” springs

180-liter Long Ranger rear fuel tank

New 16x7 wheels and BFG All-Terrain tires

INSURANCE: progressive.au. and then Assurantiekantoor Alessie (Neth.) for Africa

SHIPPERS: International Vehicle Shipping Services (IVSSUK); Trade Ocean in Namibia

COST: Total investment to date, not including the Recaro seats or repairs, is $43,000 US.

MILEAGE TO DATE: 18,000 mi / 29,000 km over 4 years, 3 continents

Will it, or won't it? The new Defender Hard Top.

Small(er) diameter steel wheels? Check. Coil springs? Check. (air springs optional on the 110). Seat delete for more cargo space? Check. Lower price? Check.

All this is fine, but as far as I’m concerned the best thing about the Defender Hard Top is that it deletes the bizarre body-color side panel for a business-like solid rear quarter. It’s the only version of the new Defender in which, if you squint just the right way, you can kinda sorta see a few styling elements from the original Defender—the flat back (“Verticality,” in LR manager Gerry McGovern-speak), the outward bulge of the body below the greenhouse. These elements are present on the standard Defender as well, but they are completely overshadowed by that illogical square of body color stuck where no body color should be.

(I’m not even going to mention the “Adventure Pack” Flintstones lunchbox option available for the same spot.)

From Land Rover’s press office, here’s the rundown on the Defender Hard Top.

Land Rover has experienced unprecedented global demand for New Defender 90 and 110 since its successful world premiere last September and the new Hard Top models will be the next additions to the legendary bloodline.

Defender’s aluminium-intensive D7x body architecture is three times stiffer than the best body-on-frame designs. Sharing its strong body structure and next-generation Electrical Vehicle Architecture (EVA 2.0) with passenger models, the Defender Hard Top is being developed by Land Rover Special Vehicle Operations to deliver unrivalled durability, practicality and toughness.

Michael van der Sande, Managing Director, Land Rover Special Vehicle Operations, said: “We will maximise the functionality and usability of New Defender’s cargo area, with tough materials and clever storage solutions to ensure it surpasses the capability of any previous Defender Hard Top.”

The 90 and 110 Hard Tops will both feature independent coil-sprung suspension, with advanced electronic air suspension also available on the 110. Both set-ups will provide outstanding off-road geometry, with ground clearance of 291mm, while the 110 Hard Top will have approach, breakover and departure angles of up to 38, 28 and 40 degrees respectively (in Off-Road height). Full technical details will be confirmed later this year.

Nick Collins, Land Rover Vehicle Line Director, said: “New Defender 90 and 110 Hard Top will be the toughest, most capable and most connected commercial 4x4s we have ever produced. They have been engineered to meet global safety standards and deliver impressive long-haul comfort, giving businesses and professionals the best of all worlds.”

An impressive payload and towing capacity of up 3,500kg* will combine to make New Defender the ultimate commercial 4x4. The flexible cabin has no second or third-row seats, but the optional front-row jump seat means it will still accommodate up to three people. Land Rover’s clever ClearSight Rear View mirror system preserves rearward visibility when the jump seat is occupied, or when the load space is full. It uses a live video feed from a rear-facing camera to give drivers an unobstructed view at all times.

New Defender Hard Top will be a world-class tow vehicle, with a raft of technologies to help hitch, drive and reverse safely while pulling a trailer. Land Rover’s intelligent Advanced Tow Assist system takes the stress out of difficult reversing manoeuvres by letting drivers steer trailers with their fingertips using a rotary controller on the centre console.

The maximum wading depth of 900mm is also supported by a new Wade programme in the Terrain Response 2 system, which ensures drivers can ford deep water with complete confidence – so important supplies will always get through.

So far this sounds like a new Defender a real overlander could appreciate.

But will it come to the U.S.? Sadly, all indications are that it won’t. The Hard Top is aimed at commercial users, and Land Rover has hope measured in negative integers of breaking into any commercial market in the U.S. The press release for the Hard Top was not even forwarded to U.S. news sources.

In all logical probability our choices will be restricted to the more upmarket versions of the Defender. They will still be impressively capable vehicles, but more expensively equipped and mounted with larger-diameter wheels and rear seats. And that panel.

If I got one, the first thing I’d do would be to take it to a body shop and have that panel painted.

Paraphrasing Mick Jagger:

“I see that panel and I want it to turn black. No color any more I want it to turn black . . .”

Step 22 Gear's Silent Jack

I know what you’re thinking, but keep reading. This isn’t just another polyurethane handle keeper.

Some time ago I wrote about my homemade Hi-Lift jack keeper, here. It functions superbly in terms of keeping the jack handle secured, with no possibility of the keeper shifting. However, my keeper does nothing to reduce the rattling of a stowed Hi-Lift, which can be annoyingly loud if, say, you have the jack mounted on a roof rack above the driver or passenger window, as many of us do, or vertically in front of a door, as some FJ40 and Jeep owners do.

Enter the Step 22 Gear Silent Jack. The polyurethane handle keeper is more or less the same as a hundred others—although I found it fit tighter (better) than most. The trick to this keeper is the second molded piece that wedges between the base of the handle and the shaft:

This piece locks the entire jacking mechanism solid, completely eliminating movement. Remove the jack’s foot (easy with Step 22’s spring-loaded base-plate pin) and there is no noise, period.

The fit is very tight—I had to squeeze hard to get the handle keeper over the handle and shaft with the wedge in place—but that indicates to me it should stay effective for a long time. You also have an extra piece to keep track of, but that shouldn’t be a big deal. I found it t be a simple but worthwhile update to the standard poly handle keeper.

Step 22 is here. Take a look at their equipment cases too. I’m hoping to try one of their tool cases soon.

"Bespoke" Autohome tent for the new Defender

It’s astonishing how quickly aftermarket companies can produce accessories for new vehicles—especially highly complex products as winch bumpers and suspension systems.

In the case of Autohome’s new “bespoke” roof tent for the new Land Rover Defender, the designers probably didn’t have to work too hard. As near as I can tell from the specifications, the Defender tent is identical to Autohome’s stock Columbus Small XL clamshell model that you can install on any Plebeian 4Runner or Pathfinder, except perhaps for the color. Looking at the photo, it’s possible the company altered the profile of the side door a bit to better match the Defender’s optional side ladder, but that seems to be it.

Regardless of how actually “bespoke” it is, Autohome tents are of uniformly excellent quality, so if you’ve bought or ordered a new Defender and are planning to install a roof tent on it, these are worth considering.

NATO fuel can FAIL (in context)

I can smugly claim to be a pioneering adopter of the NATO jerry can—pioneering, at least, in terms of North American overland travelers.

Like most U.S. 4x4 owners in the 1980s I carried spare fuel in the typical “Blitz” can, developed by our military during WWII. And I loathed them.

Their wide screw-in caps leaked. Always. No matter how I levered them closed with the biggest screwdriver I owned, any exposure to burning Arizona sun in weather over, say 60ºF would cause fumes and fuel to seep out around the gasket. As if that weren’t bad enough, fully half the ones I owned also leaked around the crimped bottom seam. The screw-in spouts available for the cans leaked as well, and were glacially slow in dispensing the contents. Filling the FJ40’s tank from one of the infernal things was always a smelly, protracted, curse-rich job.

At some point back then—perhaps in an early Tom Sheppard article, I don’t exactly remember—I read about and saw a photo of the NATO can, the genetically identical descendant of the brilliant WWII German Wehrmacht fuel container.

The Germans had developed a fuel can that was formed in two vertical clamshell haves and perimeter-welded together, creating an absolutely leakproof container. The spout/filler, likewise, was welded on, and secured with a cammed lid that put tremendous pressure on the sealing gasket yet opened easily. It was long enough to eliminate the need for a separate spout in many circumstances. The three handles were designed so that one man could carry two empty cans in each hand or a balanced full one in each, and so that full cans could be quickly passed down a line of soldiers unloading them from a truck or plane. When necessary, a separate, leakproof pour spout used the same cammed attaching system and incorporated a breather that quickly emptied the contents with zero spillage.

In the North African Campaign of 1940 and 1941, the British charged with holding back the Italians from the Suez Canal received their fuel in squarish four-gallon containers so criminally flimsy they were universally referred to as Flimsies. On a transport flight, a ship, or a truck carrying supplies to the front, it was accepted that 20 to 30 percent of the fuel would be lost through leaking or bursting Flimsies (at least one ship was lost to the resulting fire). Their best feature was that the tops were easy to cut off, so the bottom could be filled with petrol-soaked sand and lit to use as a cooker. The hack was known as a Bengazi Burner.

From left, an early (WWI-era), strong but heavy British two-gallon container, two Flimsies, and a Wehrmacht fuel can.

Once the Germans showed up to reinforce the Italians, Brits did not have to wrestle with national pride to scrounge and employ the superb containers Rommel left behind on his retreat to Tunisia. They sent examples home, the MOD with a similar lack of false pride immediately began replicating them—and the rest is history.

Except . . . some of those Wehrmacht cans were also sent stateside. And instead of simply copying them, those in charge of U.S. procurement decided to cut costs. They substituted a crimped bottom seam for the welded seam, and simplified the lid as well. In fact the only feature carried over was the triple handle. While our troops might not have been dismayed by a little leaking fuel, they couldn’t have known what they were missing when it took them two minutes or more to empty a Blitz can into a Jeep while under fire, while German soldiers were filling their Kubelwagens in half the time.

Thus, in 198 . . .? I found a source for surplus NATO jerry cans and bought two at hideous expense—I think they were $50 each at the time when a new Blitz can could be had for $8.99.

And I’ve never looked back. I’ve never had a NATO can leak through a spout gasket, even when the can was only half full of fuel in 100º-plus weather and the sides of the can bulged from the expanding air inside. I’ve stored them full on their sides without issue. Roseann and I drove through Baja in our FJ55 with a full NATO can secured inside—no, not a smart thing to do, but it never even gave off a whiff of odor.

In 1993 I had a beautiful rear spare-tire rack and jerry-can holder made for the FJ40 by a company in New Mexico called Stout Equipment (sadly no longer in existence). I decided it needed a pair of cans of equal style, and found two surplus German cans, marked “Treibstoff Feuergefärlich 20L.” They were undated but in excellent condition, and each came with a tag holder next to the spout, along with a selection of metal tags to slip in to the holder to identify the contents.

For the next 27 years those two used cans served as my auxiliary fuel containers. Every few years I repainted them with a rattle can; once I treated them to new filler gaskets. They served flawlessly.

Until the other day.

I walked out to the Land Cruiser, smelled fuel, and noticed a stain under the rear carrier. After two and a half decades of being clamped down on the rack (and whatever service came before that), a tiny stress crack, perhaps an eighth of an inch long, had opened up on one side. I decanted the gasoline into the 40 and set the can aside to dry.

If this had happened in the field I could have repaired it with some JB Weld and carried right on using it, but I think it’s earned an honorable retirement.

And the final good thing is, this product is entirely recyclable and/or biodegradable. I seriously doubt many of the military’s current plastic Scepter fuel cans will still be in service in 30-odd years, and when they are retired there’s a good chance they’ll wind up in tiny bits circulating in the Pacific Ocean.

Long live the NATO fuel can.

New, high-quality NATO fuel (and water) cans are available from Wavian.

Our 2012 Tacoma — ready for a new home (Update: SOLD)

We are selling our 2012 Toyota Tacoma, which has given us eight years of nearly flawless service.

Specifications:

Extracab SR5 4x4

4.0-liter V6, six-speed manual transmission (millennials need not apply . . . kidding!)

Power windows, locks, and mirrors

Bucket seats

Factory stereo/CD

Temperature/compass, backup camera in the rear-vew mirror

17-inch factory alloy wheels (5)

More:

ARB winch bumper, Warn 9.5XP winch with synthetic line

ARB locking rear differential with High Output air compressor and tire inflation

Yaesu two-meter radio

Trailer brake controller

Brand new BFG All-Terrain tires (5)

Brand new Bilstein shocks

Brand new brakes front and rear

New clutch at 50,000 miles

Mud mats plus the original factory carpet mats

Mechanically I think it would be difficult to find a truck in better condition. At 89,000 miles it has had nothing but synthetic fluids in the engine and drivetrain. The engine oil is still translucent at each service interval.

The bad:

Two dime-sized spots of touch-up paint high on the right rear fender

A fairly deep scratch on the glove box door and scuffing on the rear seat backs

Minor chipping on the edge of the driver’s door

The truck is ready for new adventures—$18,500 makes it yours.

Email for a look and drive [location: Tucson, Arizona]. Note: Mask required! No mask, no drive, no sale. Thank you.

Warn's "new" M8274 winch

When a product stays in production for a half century with virtually no change to its configuration or specification, you know the original designers were inspired with genius.

Such is the case with Warn’s M8274 winch. Introduced in 1974 as a mere tweak or two upgrade from the even more venerable Belleview winch (from 1959), the 8274 combined excellent power (8,000 pounds) with massive cable capacity (150 feet), and spur drive gearing that was not only superior in strength but more efficient than any other winch driveline on the market—75 percent, compared to 40 percent in the only other winch that can claim equally legendary status, the worm-drive Superwinch Husky.

The 8274 could also claim the fastest loaded and unloaded line speed of any production winch—an “advantage” that to my mind was not all that advantageous, since generally when I’m winching I want the process to proceed as steadily and slowly as possible. But some people like the speed, and in competition 8274s were commonly hotted up with second motors to increase speed still more.

Another advantage to the 8274 became apparent with the advent of synthetic winch line. The brake on the winch is external to the drum, which meant there was no chance of overheating the line when winching in reverse.

The 8274’s only practical disadvantage was its height and foot-forward mounting system, which required a dedicated bumper and a vehicle with clearance for the height. On my FJ40 it was a match made in heaven.

Thus from 1974 through 2019, the 8274 remained virtually unchanged. Now, however, Warn has announced a “completely new” version.

The “new” 8274 now boasts a 10,000-pound capacity thanks to a six-horsepower motor (although they have retained the 8 in the model designation, which referred to the original’s capacity). It can also be had from the factory with synthetic line. Importantly, the original solenoid-based switching mechanism for the motor has been replaced with a waterproof, solid-state Albright contactor. The solenoids, while durable, were not waterproof, and could on extremely rare occasions freeze in the closed position, which meant the winch would keep pulling even if the operator let go of the remote button.

So, why did I state “through 2019” rather than 2020, and why did I put “new” in quotes?

Because we have already seen this winch. It was introduced last year as the 70th Anniversary model (see here), with the same 10,000-pound capacity, Albright contactor, and synthetic line. What Warn has (apparently) done is to simply make the anniversary model the new standard 8274. Even the list price, an eye-watering $3,199, is the same.

Notwithstanding that tiny bit of marketing legerdemain, the new Warn 8274 looks set to enjoy another several decades as the winch against which all others are measured. If you have a serious expedition vehicle with an appropriate mount, there is no better choice.

Warn is here.

Need some Covid reading?

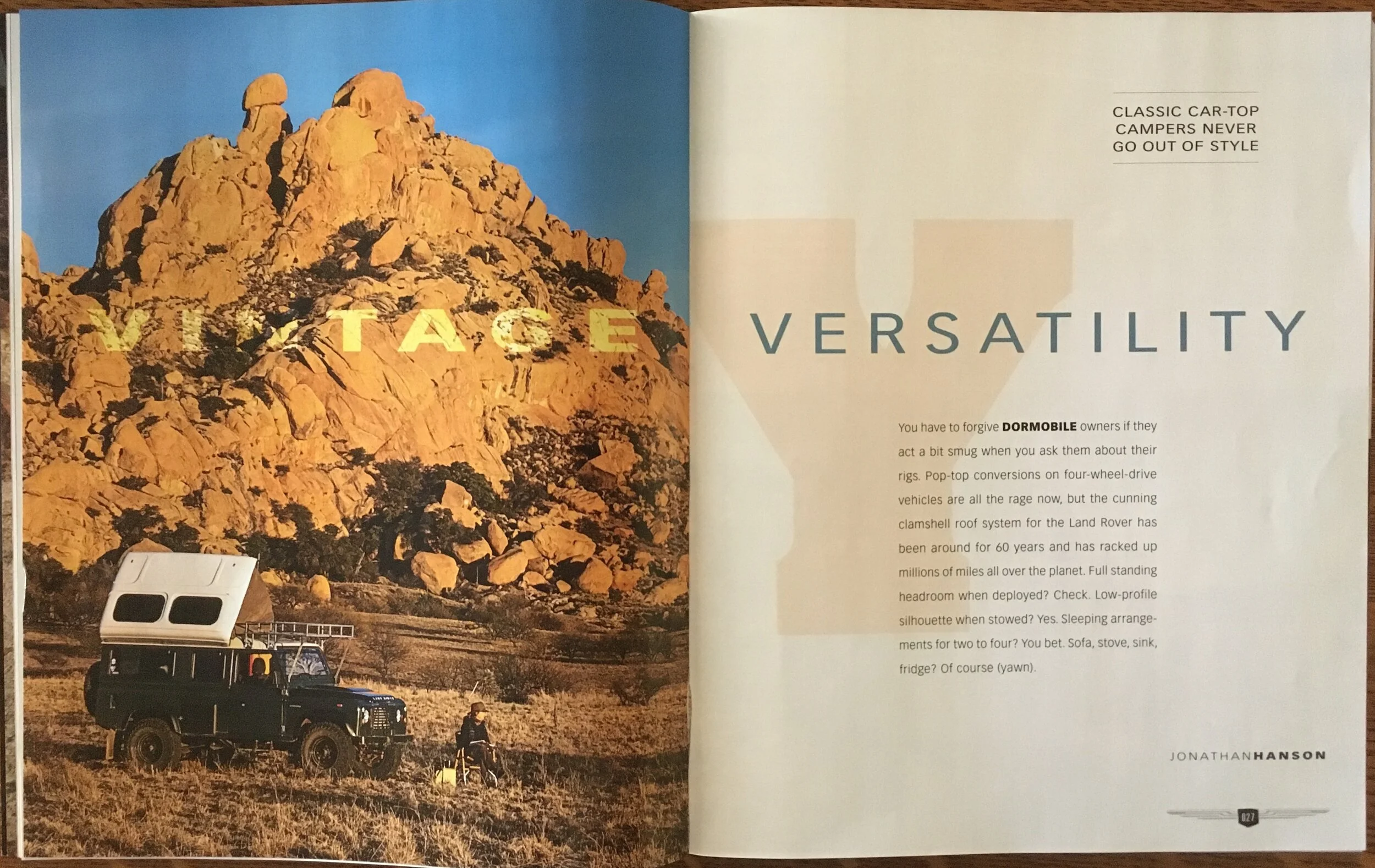

May I suggest the spring 2020 issue of Wheels Afield? In addition to an article about overlanding through Namibia in search of desert elephants and black rhino, and another featuring a fabulous custom Land Rover Defender 110 Dormobile—both by yours truly—there is another piece on exploring Baja by my friend Chris Collard.

If, as I suspect, your local bookshop is closed, you can order a copy here, for $10 postpaid.

Help me keep getting assignments! Thank you.

Hint: When using “Search,” if nothing comes up, reload the page, this usually works. Also, our “Comment” button is on strike thanks to Squarespace, which is proving to be difficult to use! Please email me with comments!

Overland Tech & Travel brings you in-depth overland equipment tests, reviews, news, travel tips, & stories from the best overlanding experts on the planet. Follow or subscribe (below) to keep up to date.

Have a question for Jonathan? Send him an email [click here].

SUBSCRIBE

CLICK HERE to subscribe to Jonathan’s email list; we send once or twice a month, usually Sunday morning for your weekend reading pleasure.

Overland Tech and Travel is curated by Jonathan Hanson, co-founder and former co-owner of the Overland Expo. Jonathan segued from a misspent youth almost directly into a misspent adulthood, cleverly sidestepping any chance of a normal career track or a secure retirement by becoming a freelance writer, working for Outside, National Geographic Adventure, and nearly two dozen other publications. He co-founded Overland Journal in 2007 and was its executive editor until 2011, when he left and sold his shares in the company. His travels encompass explorations on land and sea on six continents, by foot, bicycle, sea kayak, motorcycle, and four-wheel-drive vehicle. He has published a dozen books, several with his wife, Roseann Hanson, gaining several obscure non-cash awards along the way, and is the co-author of the fourth edition of Tom Sheppard's overlanding bible, the Vehicle-dependent Expedition Guide.