Overland Tech and Travel

Advice from the world's

most experienced overlanders

tests, reviews, opinion, and more

Vehicle-dependent Expedition Guide, edition 4.1a

I’m happy to announce that we just received a shipment of the Vehicle-dependent Expedition Guide, edition 4.1a. As you might surmise from that “4.1a,” this is a tweak of edition 4.1 rather than an entire re-write as that one was. Notable updates can be found in the electronics and navigations sections as well as scattered here and there. Most obvious is a drive and critique of the new Defender.

I’ve been asked by owners of previous VDEG edition if this one is worth upgrading to. If you own any edition prior to 4.1, I’d say absolutely (also if you’re one of several people I know who have diligently collected every edition). Tom and I drastically updated 4.1 and added almost 100 pages, with much more information of value to North American readers. If you have a copy of 4.1 and are not considering a new Defender, or a long-range trip dependent on GPS navigation, you’re probably fine. Fair enough?

The three-and-a-quarter pound, 600-plus page VDEG remains, quite simply, the bible for anyone contemplating overland travel, from three-day jaunts into nearby national forests, to multi-month transcontinental research expeditions. Along with Four-by-four Driving, it is used as a reference by Special Forces units in two countries.

Available here.

Antigravity’s new LiFePO4 batteries

One morning in the early 1990s, when I was still leading sea kayaking tours in Mexico, I found myself stranded on a remote beach at the end of a tour with a suddenly dead Sears Die-Hard battery in my FJ40 (this was before I’d ever heard of a dual-battery system). Rather embarrassed, I got a jump start from a client, sent everyone home ahead of me, then drove the entire way back to Tucson, towing a trailer full of kayaks, without turning off the engine. (It took some doing to convince the U.S. customs people I wasn’t just preparing to do a runner after I was pulled into the inspection lane. In an FJ40 pulling a trailer? They could have caught me on foot.)

Not the best place for battery failure.

The battery was well within its pro-rated warranty period, so once home I got a new one for around half price. But that really wasn’t the point, was it? If I’d sent everyone home before discovering the dead battery, I would have had a very long walk to the nearest fishing village—I certainly couldn’t have push-started an FJ40 solo in beach sand. I was also aware of other circumstances I’d been in that could have been as bad or worse if a battery had failed. My experience with Die-Hards—then the much-hyped premier battery on the market—was that they lasted an average of two years before failing, usually abruptly.

There had to be a better way. I did some research (remember when that took actual effort?), which led me to news of a recently available type of über SLA (sealed lead acid) battery called a “gel cell” or AGM (for absorbed glass matt). A company called Optima made them, and the one that suited my FJ40 was around $130 special order—an outrageous price when a Die-Hard went for $55. I winced and ordered one anyway, and that first red-top Optima lasted six years before—very politely—showing signs of weakening. Thus, not only did it prove less expensive in the long run, it saved me at least two battery failures that could have happened anywhere. The AGM battery (I switched to Odyssey later on) became my standard battery configuration—as did a dual-battery system.

Twenty five years later there is a new über battery on the market, with a price as startlingly higher than a typical AGM as that Optima was higher than the Die-Hard. Does the lithium iron phosphate, or LiFePO4, battery represent as much of a leap as the AGM did? Can an overlander on a modest budget justify spending $800 or more for a single battery?

I’d like to find the answer—for myself as well as readers who might be contemplating the upgrade. So I’ll be installing a new dual-battery system in our Land Cruiser Troop Carrier, using one of Antigravity’s new DC-100-VI deep-cycle LiFePO4 batteries, along with one of their already introduced LiFePO4 starting batteries.

Not your father’s car battery . . .

I’ve been a fan of Antigravity’s products since their pioneering, pocket-sized Micro-Start jump-starting unit, which I embraced very early on and with which I’ve astonished more stranded motorists than I can count, including dozens at several Overland Expos who immediately headed for the Antigravity booth to buy their own. I also astonished, and rather horrified, Scott Schafer, the founder of the company, when I called to tell him that Tim Scully and I had successfully daisy-chained three Micro-Starts and performed an excellent field weld. That function was definitely not within his original design goals—yet we still have all three of those units and they still work perfectly.

NOT recommended!

Given that history, I have every expectation that Antigravity’s LiFePO4 automotive batteries will display similar quality. But I had to promise Scott I wouldn’t try welding with them.

So what’s all the fuss about LiFePO4 technology?

Most articles covering lithium batteries (to use the convenient shorthand) immediately mention the weight savings. And that aspect is impressive—The 100-amp-hour deep-cycle battery Antigravity sent me weighs 30.5 pounds; an equivalent Odyssey AGM unit weighs 69.5. Switching to a dual-battery system employing both starting and deep-cycle lithium units will, in our case for example, completely offset the weight of our 60-liter National Luna fridge-freezer. With a case of beer inside.

Thus there is an obvious advantage in energy density to the lithium battery. However, it’s even greater than the weight difference implies.

Consider a deep-cycle AGM battery and a deep-cycle LiFePO4 battery, each rated at 100 amp hours. While that seems equivalent on the surface, in delivery it is not. As soon as a draw is placed on an AGM battery, its voltage begins to drop in a more or less linear fashion. Once that voltage drops below 10.5 or so, a 12V appliance such as a fridge will shut itself off. At that point the battery retains nearly 50 percent of its theoretical energy, but it is unavailable to a 12V appliance because the voltage is too low.

By contrast, the energy delivery of a LiFePO4 battery is a nearly flat line that remains above 12 volts until the unit is almost fully discharged, at which point it drops off rather rapidly. Thus you get far more actual available power from a lithium battery than you would from an “equivalent” AGM.

But that’s not all. A LiFePO4 battery is also capable of accepting a charge at three to four times the rate of an AGM battery. A typical AGM in a vehicle can take as long as 10 hours to recover from a completely discharged state. A LiFePO4 battery can be recharged completely in four. And while an AGM battery typically can withstand around 300 such discharges, a lithium battery can withstand around 2,000—which brings up the last comparison: lifespan and amortized cost.

Currently a high-quality LiFePO4 battery costs two and a half to three times as much as a high-quality AGM battery from a manufacturer such as Odyssey. However, it appears likely the lithium battery will outlast the AGM battery by about the same factor—if not more. Thus over time the LiFePO4 battery should recoup its cost—and that doesn’t count the hassle of having two or three AGM batteries fail in that time. On an amp-hour basis, there’s no comparison—the LiFePO4 delivers far more energy over its lifespan.

(This obviously assumes that you keep your vehicle for a long time, or that you swap the lithium batteries from old truck to new truck, and say, “Get your own!” to the buyer of the old one.)

There are other advantages. For example, the Antigravity lithium starting battery has a built-in wireless jump-start feature. Leave the lights on or in some other way run down the battery, and it will shut itself down while retaining sufficient starting power to start the vehicle. Just tap a button on a wireless key fob to activate it; you don’t even need to open the hood. (You can also hit the button on the battery itself.)

So . . . end of argument? Not quite.

The bête noire of the LiFePO4 battery is temperature, or rather temperature extremes. Most lithium automotive batteries, including the Antigravity unit, can be used (i.e. discharged) at temperatures down to -20ºC (-4ºF). However, they cannot be charged at temperatures lower than about 0ºC (32ºF). The Cliff’s Notes reason for this is that, when recharging at temperatures above 0ºC, the lithium ions are absorbed by the porous graphite that comprises the anode—the negative side of the battery. Below this, the lithium instead begins sticking to the outside of the graphite, a process called lithium plating. This not only reduces efficiency but can permanently damage the battery.

Keep in mind that these critical numbers represent the internal temperature of the battery, not the ambient air temperature. As the outside temperature drops, the internal battery temperature will lag significantly. A night that drops to freezing or even several degrees below is unlikely to chill the internals to critical level—and we never charge batteries at night anyway. Also, drawing power from the battery—even for efficient LED camper lights—raises its internal temperature somewhat.

Fortunately, each Antigravity battery incorporates a sophisticated battery management system (BMS), which prevents charging when the temperature drops too low. So you don’t have to worry about damaging the battery; however, this aspect might be important if you camp for long periods in persistently below-freezing weather. Antigravity is also preparing to introduce a LiFePO4 battery with an automatic internal heat source that runs off the battery itself, as some other manufacturers have done. We don’t feel the need for this in our application—for Roseann, the words “snow” and “camping” never appear in the same sentence.

(As usual, clever owners who adopted LiFePO4 technology ahead of the rest of us have figured out their own hacks to deal with the low-temperature issue. Some have combined a simple temperature-controlled switch such as this with an inexpensive 12V heating film like this.)

(Another parenthetical aside: While researching all this I came across an article detailing the efforts of NASA scientists to extend the low-temperature parameters of lithium batteries—of obvious importance when sending them into space. The article noted that engineers had significantly extended these parameters by using an electrolyte formation of—ready?—1.O MLiPF6EC+DEC+DMC+EMC (1:1:1:2 v/v) and 1.O M LiPF6 EC+DEC+DMC+EMC (1:1:1:3 v/v). If they’d only called me I would have suggested that in the first place.)

Very high temperatures can also affect LiFePO4 performance. The listed upper limit for discharging the Antigravity deep-cycle battery is 55ºC (131ºF). For this reason, some owners install their lithium “house” batteries inside the vehicle or camper rather than in the engine compartment. This has the doubled effect of keeping the battery warmer on cold nights, especially if any kind of heat source is used in the camper for the comfort of occupants.

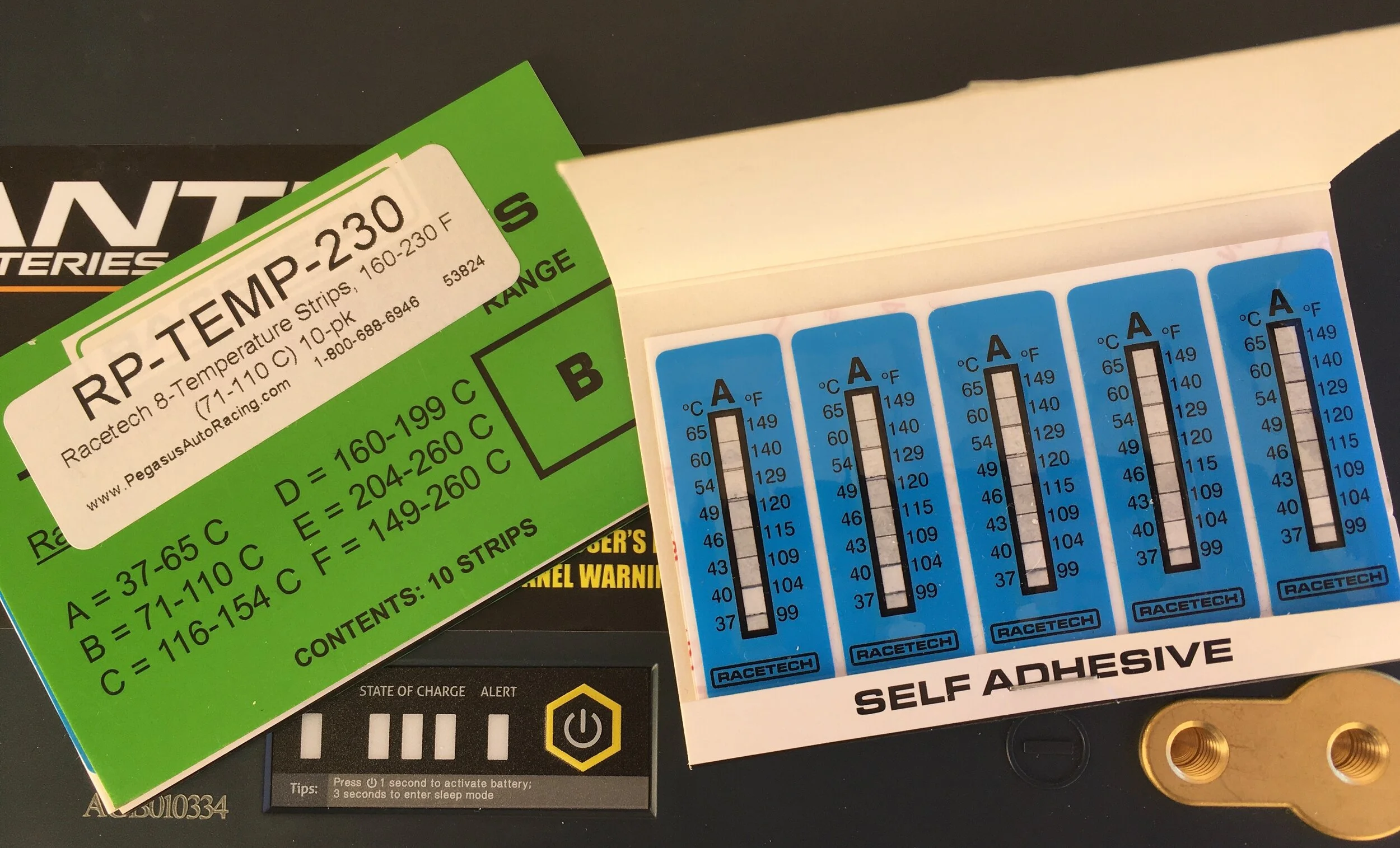

I’ve decided to take a slightly bolder approach, partially as an experiment to see the effects of different installations. Our Troopy has the stock dual-battery tray in the engine compartment, and I plan to mount both batteries there and monitor the temperature extremes they experience, using (in part) Racetech stick-on temperature strips, which record the high temperatures reached on the surface to which they’re attached.

The other part? That will be courtesy the built-in Bluetooth connectivity of each battery, which will enable me to monitor, through my iPhone:

Battery voltage

Current/amps going in or out

Watt output

State of charge percentage (SOC)

Interior temperature

Individual cell voltage

Number of cycles the battery has experienced

In addition to that internal temperature readout, the state of charge in percent will be especially helpful—given the LiFePO4’s characteristic of maintaining flat voltage delivery, it’s difficult if not impossible to ascertain the state of charge by voltage alone, as on an AGM battery.

Our Troopy’s battery tray is in the back right corner of the engine compartment, looking from the front of the vehicle. The 1HZ diesel’s exhaust manifold is on the opposite side of the engine, which will help mitigate heat gain. I also plan to have fabricated a metal heat shield that will block the inside faces of the batteries, to help even more. I’ll add some sort of heat barrier to the sheet metal as well. In a few months the southern Arizona summer should give us some solid data on the effects on both batteries; then we can re-evaluate their placement.

I’m going to take the opportunity to replace the existing cables and terminals with new ones, and clean up the rather tangled routing resulting from adding on the winch, driving lamps, and National Luna isolator.

There is one other cost factor to consider when considering a LiFePO4 battery. As I mentioned, a lithium battery has a very different charging profile from an AGM battery. Thus, for the deep-cycle unit I’m installing in the Troop Carrier, I’ll need to swap the existing DC-DC charger, designed for AGM batteries, for one that includes a setting for lithium batteries and is suitable for routing and managing both alternator and solar power to the Antigravity battery. Such units can run from about $300 to $400. This is pretty much a one-time outlay, but it still needs to be factored into the initial investment.

I’ll be doing regular updates here as soon as the starting battery arrives.

Book debut: Trail of the Jaguar

Jonathan’s new 400-page novel, Trail of the Jaguar: A Clayton T. Porter Adventure debuted at the Tucson Festival of Books online March 6 and 7, and you can pre-order now for delivery after March 15.

What could be better than a thriller that features endangered jaguars and an HZJ75 Land Cruiser pickup chasing the bad guys?

From a reviewer:

“The drug cartel madness of the Borderlands, combined with the corruption of federal agents, is suddenly dropped into the lap of wildlife photographer, biologist, and tactically trained anti-poacher Clayton T. Porter, whose reaction in self defense initiates a cascade of violent events. His discovery of internationally threatened jaguars being employed as executioners by a drug cartel, and used as targets in canned hunts by unscrupulous U.S. physicians, leads to assaults on those closest to Clayton. Buckle up for a wild ride through the hinterlands of southwest Arizona and northwest Mexico as Porter embarks on a journey of total retaliation.”

Dexter K. Oliver, author of The Raven’s Beak and Journal of a Wayfaring Writer

Publisher : Natural Selection Press

Language : English

Paperback : 400 pages

ISBN : 978-0-9910019-5-8

Item Weight : 14.1 ounces

Dimensions : 8 x 1 x 5 inches

Printed in the U.S.A.

Pre-order signed copies now, to be shipped after the Tucson Festival of Books—HERE.

Used 4x4? Digital odometer? Beware . . .

A confession: Back in the days before Roseann straightened me out, my friend Michael and I once rented a cheap econobox to drive from Tucson to San Jose, California, and back, to see the flat-track motorcycle races there. The least expensive contract specified a total of 200 miles for our rental period—and wouldn’t you know, we turned that car back in with 187 miles on the mechanical odometer.

Employing a bit of legerdemain was easy on those odometers, using little more than a screwdriver and a pen knife. When digital odometers became standard, I remember thinking those days were over.

Apparently not.

A friend recently bought a Toyota pickup advertised with 187,000 miles. Through a bit of miscommunication between husband and wife, the Carfax report was not studied until after the purchase—at which point it was discovered the truck had covered about twice that distance.

It turns out that, with a simple and cheap tool, a digital odometer can be altered with far more ease than a mechanical model. And according to reports such as this one, it’s becoming more and more common.

Caveat emptor.

Used G-Wagen, anyone?

This showed up on a media site I subscribe to that amalgamates vehicle news from around the world. The, er, heavily modified vehicle is coming up for auction, the property of a “famous footballer (soccer, that is) who wishes to remain anonymous.”

If I owned this thing I’d want to remain anonymous too. Yet clearly he didn’t care about anonymity while he owned it.

Why would someone do this to an SUV? Just buy an AMG sedan!

Old Man Emu suspension

Let’s be honest: Drivers of newer Jeep Wranglers, first-generation Land Rover Defenders, and Mercedes Benz G-Wagens—all of them equipped with solid axles front and rear but also supple coil suspension—have every right to snicker at the 19th-century leaf springs gracing all four corners of 1984-1999 Land Cruiser Troop Carriers, and the rear axles of Troopies to this day (Tom Sheppard are you reading?).

Did I say 19th century? The first crude “elbow” leaf springs appeared on carriages in France in the 1600s. But the elliptical leaf spring, patented by Obadiah Elliott in 1804, would be recognizable by any Land Cruiser owner today.

Why has Toyota stuck with semi-elliptic leaf-spring suspension for so long on the Troop Carrier and its derivatives, especially when other versions of the Land Cruiser have had all-coil suspension since 1991? Two reasons, essentially: simplicity and cost.

A leaf spring not only performs its primary function of suspending the vehicle, it also locates the axle front to rear and side to side. A coil spring does neither; the axle must be located front to rear by either trailing or leading arms, and side to side by a panhard rod or something similar. This increases complexity and cost and, some would argue, decreases strength and reliability (a notion with which I do not agree.)

Of one comparison there is little doubt: A leaf spring cannot match a coil spring in ride comfort or compliance.

The major reason for this is the combination of interleaf stiction—which resists the sliding movement of the leaves in the first place—and friction, as, once set in motion, each leaf in the spring pack slides back and forth along the underside of the leaf above it with bumps and dips, while the leaf below slides along that one’s underside, and so on—all this in a pack that might have ten or more leaves. Even with brand-new springs still covered in factory paint and grease, interleaf stiction and friction is inevitable. Once the springs are a couple of years old, paint worn off and rust in its place, it only gets worse.

This interleaf friction can have benefits, for example in the event of shock absorber failure—a leaf-sprung vehicle with one or even all of its shocks removed is bouncy but drivable, as the interleaf friction affords a damping effect. A coil-sprung vehicle minus shocks is dangerous, as a coil spring has scant internal stiction or friction. But that’s a microscopic upside.

Thus the challenge facing a suspension designer working with leaf springs is to create a spring that will carry the necessary load, which is easily done by employing more or thicker leaves, while as much as possible reducing stiction and friction to enhance ride comfort, which is easily done by employing thinner or fewer leaves. You see the problem.

When Roseann and I bought our 1993 Troopy, sight unseen, from 6,000 miles away (we in the U.S.; the Troopy in Darwin, Australia) we were fully aware that we were taking chances on numerous aspects of the vehicle’s condition. Mostly that condition turned out to be just fine, aside from significantly more rust than had been advertised. However, after having the vehicle shipped to Sydney, we then embarked on several major modifications, also long distance, some of which worked and some of which did not.

The big one, the Mulgo pop top, met all our expectations, and Daniel at the Expedition Centre was a pleasure to work with. Likewise, the Warn winch and ARB Intensity driving lamps he installed were everything previous experience had led us to believe they would be. Cabinetry Roseann sketched and emailed and which Daniel had fabricated turned out perfect in function and adequate in construction (I would have chosen better plywood and not left poorly filled screw holes so obvious). Daniel installed Recaro seats, a massive improvement on the sagging stock units, and a 90-liter water tank that has been awesome.

After our first Australia trip, across the Simpson Desert via the Madigan Line, it was apparent the existing suspension was inadequate to carry the increased weight of our modifications. I was strongly inclined to go with Old Man Emu as a replacement, having had it on our FJ40 for a couple of decades. But we were nudged toward a company with the modest title of Ultimate Suspension, who provided us with a sophisticated graph of the existing suspension’s performance or lack thereof. They installed a new set of springs and shock absorbers, as well as a set of “Sumo Springs” on the rear axle—an add-on I resisted but was assured would be excellent for helping to support the load.

That suspension definitely supported the load. Compliance? I suspect steamrollers have more. This was especially apparent in the rear, where the Sumo Springs further inhibited axle movement. Since they are nothing but elongated rubber doughnuts, I wasn’t surprised.

Nevertheless, we completed three more trips in Australia and Tasmania on that suspension—mostly. On our last leg, to Perth on the west coast, where we were to container our vehicle, along with Graham Jackson and Connie Rodman’s, for the crossing to Africa, the Troopy developed a mysterious noise amplified through the steering column. Graham and I failed to locate it, but a shop in Perth assured us it was the front springs, even though by then I suspected it was in the steering column itself. They installed a complete new set of front springs just one day before we had to leave the vehicles at the port. As I drove away after paying, the noise was still there (it indeed later proved to be a harmless steering column clunk). I drove back and took the shop manager for a ride. He quickly admitted the wrong diagnosis, but by then it was too late to replace the “old” springs, so we got a large chunk of refund.

On our drive across southern Africa, through South Africa, Botswana, and Namibia, we soon realized the new front springs were even worse than the Ultimate springs. They had far too much arch, so that the shackle angle was completely wrong (it should be at or close to 90 degrees to the spring). Ugh.

Once back home with the Land Cruiser, we stewed over the waste of money but were too busy with other projects Finally, while helping Graham lead a trip through Utah and Colorado, I became terminally annoyed at the reduction in off-pavement capability the Ultimate/Perth suspension was causing, along with the reduction in the compliance of my lumbar disks. Once home, I got under the Troopy, only to find one of the Ultimate shocks, which by that point had perhaps 15,000 miles on it, totally blown, in addition to which one of the Sumo Springs had ripped free of its base plate. As an experiment, I pulled the smallest leaf out of the front springs, which made scant difference in the bad shackle angle or the ride.

Sumo Springs . . . gone!

That did it. After a consultation with Kurt at Cruiser Outfitters, I ordered a complete Old Man Emu suspension system. OME springs are individually specced for load, so I specified heavy in the front, to accommodate the ARB bumper and winch, and Heavy Plus in the rear, to accommodate the cabinetry, pop-top, rear Kaymar bumper, rear Long Ranger 180-liter fuel tank, etc. etc. . . .

The springs came with matched shocks, greasable anti-inversion shackles, a new steering stabilizer, even new bushings and hardware for the ends of the front anti-roll bar (or “stabilizer” bar). Over the course of a weekend I installed everything, then went for a drive. Ten minutes later I came back and put Roseann in the passenger seat. About a hundred yards down our residential street she said, “Wow!” Yeah, the difference was that stark. A hundred-mile trip the next day confirmed the massive improvement in ride and compliance.

Why? Measuring the total thickness of the spring packs at the spring seat (the thickest part), was somewhat surprising: The Ultimate and OME rear springs were exactly the same thickness (9.7cm), as were the Perth and OME front springs (5cm). However, the OME springs employed more and thinner leaves to achieve this thickness—12 versus 11 leaves on the rear, 8 versus 7 in the front. Also, unlike either the “Ultimate” rear or the Perth front springs, OME employs nylon anti-friction pads at the tips of the most normally active leaves. Far from being just a gimmick, I found these to work exactly as advertised on my FJ40, as long as I pried apart the leaf ends and gave each pad a shot of grease every year or so. They also do wear out eventually and must be replaced, so should be considered a maintenance item.

Anti-friction pads are visible here

Unlike the Ultimate springs, the OME springs are also tapered and diamond-cut at the tips, which ARB claims distributes the load over a larger surface area—which would also reduce friction. I have no testing results to back this up, but it is obviously a more expensive way to build a spring leaf so one assumes there is a good reason to do so.

Square-cut, untapered “Ultimate” leaves

Versus diamond-cut, tapered OME leaves

Finally, the greasable shackles contribute a bit to the overall flexibility of the springs. Only the center pin of each bushing is greasable, because the bushing only rotates around that pin, not the outer circumference.

Right now the Troopy sits exactly level (with proper shackle angles), with mostly everything aboard but without the rear fuel tank filled. On our first long trip I’ll do so and evaluate the stance; it’s possible to add another leaf there if necessary. The ride is so much improved that I wouldn’t hesitate to do so if needed.

Greasable shackles . . . and correct angle

And, next time, I’ll listen to my own experience and not be talked into the “Ultimate” solution.

The 2022 Nissan Frontier

Apparently the execs at Nissan finally realized with some alarm that the Frontier pickup was in danger of upending the VW Beetle’s claim to the longest unchanged model run in automotive history.

I can understand why they waited so long. Never a smashing sales success—although, astonishingly, it outsold the underwhelming new Ford Ranger in the latter’s debut year—the Frontier was nevertheless always a solid workhorse that remained just the right size while its competitors grew with each generation. In 2015 Roseann and I drove a Nissan Navara, the twin of the Frontier except for the former’s exquisite turbodiesel engine, most of the length of South America and were impressed with its unassuming competence. Still, 16 years is a geologic era in truck model lifespan, so Nissan is introducing a “brand new” Frontier this summer. Why the quotes? Because apparently the chassis is more or less identical to the previous generation—far from a bad thing, as it is a fully boxed unit compared to the sales leader Tacoma’s partially boxed counterpart. (Four wheel disc brakes also carry over, of course, shaming Toyota’s antediluvian rear drums.)

Perhaps inevitably, body dimensions have expanded, although each body style remains an inch or two smaller in each direction than the equivalent Tacoma. Styling? It’s more or less generic current-midsize-pickup normal, although the front end is pleasingly crisper than the Tacoma.

There’s a “new” V6 (introduced during the last model year)—a direct-injection 3.8-liter, following the current, lamentable fashion trend of producing more horsepower than torque: a healthy 310 hp versus 281 lb-ft. I couldn’t find any information on where in the power band each of those occurs, but I’m willing to bet the torque peak is north of 4,000 rpm, as is the case with all competitors’ gasoline engines. Personally I think a truck engine should have a torque peak below 3,000 (or even 2,500) rpm, but aside from diesel engines I’m afraid this is a characteristic of the past. I will allow that current eight, nine, and ten-speed transmissions are able to make the most of this kind of high-rpm power band, but it’s essentially worthless for a manual transmission, requiring a wince-inducing level of clutch slippage to get underway with any kind of load. Fortunately the Frontier will have an up-to-date nine-speed auto, once again leaving Toyota in the dusty storerooms of the archaeological museum with its six-speed. (I’m half-expecting Toyota to re-introduce a carbureted engine in the next Tacoma, assuring us that it’s “better off road.”)

The new Frontier will have a seven-selection mode dial for various off-pavement situations, following, of course, along with everyone else on Land Rover’s Terrain Response dial introduced a decade and a half ago.

Otherwise? Well, we still don’t have a new Frontier to inspect in person, but it was clear from the media introduction that there will be no earth-shaking innovations in the truck. What will it take for some mid-size pickup maker to blow through the envelope with, say, coil-spring rear suspension with automatic load leveling (Range Rover, 1970)? Variable valve timing that could lower the torque peak for low-range four-wheel-drive or towing situations (my own thought invention)? Intelligent weight sensors at each corner that could detect when a tire was about to lose traction and lock the axle before any wheel spin occurs (also my own thought invention)?

As long as manufacturers can keep selling trucks built the way they are now, and temporarily edge past each other’s sales with styling tweaks, larger infotainment screens, and a few extra horsepower, probably not for a while . . .

The True North Collections Jeep Wrangler

A post in a Land Rover group on Facebook alerted me to this: the True North Collections Jeep Wrangler—described in TNC’s words as, “AN AMERICAN LEGEND REIMAGINED.”

Uh oh. Any time I see the word “re-imagined” these days, the first thing I think of is a ghastly tart job on some unfortunate, formerly workmanlike and practical classic vehicle: diamond-pleated, contrasting-stitched, distressed-leather upholstery, digitized (and leatherized) dashboard, video monitors in the headrests of the Recaro seats, extraneous exterior styling bits. Usually you’ll find special badging embossed in the leather and/or displayed in bronze escutcheons on the fenders.

(There are exceptions. Singer’s glorious “re-imagined” Porsches reach a sublime plateau of craftsmanship and performance we might have expected had God spent the eighth day working on his personal 911. Another story entirely. But in general such projects have all the taste of a Middle Eastern potentate’s bathroom.)

My initial reaction to the TNC Wrangler—advertised as a 2017 model with only 400 miles on the odometer— was that for some inexplicable reason they tried to turn a Jeep Wrangler Unlimited into an original-version Land Rover Defender 110. Second reaction—same thing. The all-white U.N. paint job recalls the 500 limited-edition NAS 110s of 1993-1995. There’s the raised, Defenderesque roof with not one, but two Alpine windows, just so we get the point. folding, Defenderesque steps. The weird white solid-disk wheels, however, don’t very well replicate Land Rover Wolf wheels. De rigueur tail lamp brush guards are there. But, no checker plate on the bonnet?

Then there are the limb risers.

On all but a very few vehicles, limb risers (also called brush wires) are more or less the ultimate poseur accessory. They were originally designed for vehicles that had to push through extremely thick brush—think overgrown Central America rain forest. A few regions in the U.S. grow vegetation quickly enough that vehicles on a legitimate route might employ them effectively—narrow forest trails back east, for example. Otherwise, unless you’re driving somewhere you probably shouldn’t be, they’re strictly a fashion statement.

Look at these closely. Assuming an owner of a TNC Wrangler might actually take his vehicle somewhere limb risers might be necessary, I’m dubious that the flimsy looking mounting hardware would hold up to the stress of shoving chest-high branches and limbs up to roof height. And if it did? Take a look at the roof rack, which will function as a beautiful limb-catchment device, with a front mounting bracket a good three feet behind the front edge. Any limbs raised there would be stuffed into the gap between roof and rack, and either rip the rack off its mounts or rip bushels of branches off passing trees and leave them wedged in place. An automatic firewood-gathering device, perhaps? Let’s hope you didn’t pick up a fer-de-lance with the kindling. Additionally, the dinky Hella driving lamps perched atop the front bumper’s bull bar would either be ripped off as well or at the very least wind up aimed skyward.

There’s a winch in the bumper as well, but I can’t tell anything about it from the photos, and the TNC site is silent on its specs.

On to the interior, about which, sure enough, TNC says, “We took the stock interior and elevated it with bespoke vintage inspired brown leather.” The photos only show snippets, but I have to say this facet of the vehicle at least appears restrained and handsome—if you’re into leather upholstery in an overlanding vehicle. They also note “billet aluminum shifter, AC vents, and knobs to replace the original plastic.” (Have you ever thoughtlessly grabbed a billet aluminum shifter that’s been basking in the summer Arizona sun for an hour or two? I have.)

Obviously I’ve not seen this vehicle in person, much less driven it. But it’s fair to wonder about their target customer. A serious explorer, or just someone who wants the look and attention? Perhaps the final paragraph in the pitch is a clue:

“Included with the sale of this Wrangler is our bespoke leather luggage option, and handmade bespoke key tag with the Edition # of the vehicle as well as a coffee table book with breathtaking imagery of this Jeep in city and mountain settings. There is no truck/suv on the market today, this unique and with this much press anywhere in this price range.”

If you’re interested, the True North Collections site is here.

Hint: When using “Search,” if nothing comes up, reload the page, this usually works. Also, our “Comment” button is on strike thanks to Squarespace, which is proving to be difficult to use! Please email me with comments!

Overland Tech & Travel brings you in-depth overland equipment tests, reviews, news, travel tips, & stories from the best overlanding experts on the planet. Follow or subscribe (below) to keep up to date.

Have a question for Jonathan? Send him an email [click here].

SUBSCRIBE

CLICK HERE to subscribe to Jonathan’s email list; we send once or twice a month, usually Sunday morning for your weekend reading pleasure.

Overland Tech and Travel is curated by Jonathan Hanson, co-founder and former co-owner of the Overland Expo. Jonathan segued from a misspent youth almost directly into a misspent adulthood, cleverly sidestepping any chance of a normal career track or a secure retirement by becoming a freelance writer, working for Outside, National Geographic Adventure, and nearly two dozen other publications. He co-founded Overland Journal in 2007 and was its executive editor until 2011, when he left and sold his shares in the company. His travels encompass explorations on land and sea on six continents, by foot, bicycle, sea kayak, motorcycle, and four-wheel-drive vehicle. He has published a dozen books, several with his wife, Roseann Hanson, gaining several obscure non-cash awards along the way, and is the co-author of the fourth edition of Tom Sheppard's overlanding bible, the Vehicle-dependent Expedition Guide.